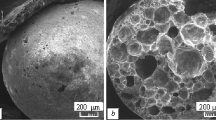

Information is provided about the thermal conductivity of highly porous refractory specimens prepared using kaolin, clay, combustible, sintering additives, and also foam. Data for the properties of samples of lightweight refractories prepared by different methods are analyzed. The emphasis is on combination of specimen heat insulation and strength properties The thermal conductivity achieved for foam samples is 0.37 W/(m·K) at 650°C in combination with satisfactory compressive strength of 3.8 MPa.

Similar content being viewed by others

References

Yu. P. Gorlov, Technology of Heat Insulation and Acoustic Materials and Objects [in Russian], Vysshaya Shkola, Moscow (1989).

Y. Guzman, “Certain principles of formation of porous ceramic structures. Properties and applications (review),” Glass Ceram., 60, 280 – 283 (2003).

G. V. Samsonov, A L. Borisova, T. G. Zhidkova, et al., (G. V. Samsonov, editor), Physicochemical Properties of Oxides: Handbook [in Russian], Metallurgiya, Moscow 91978).

V. G. Mikul’skii, editor, Building Materials [in Russian], ASV, Moscow 92000).

E. M. Dyatlova, R. U. Popov, and E. Yu. Bogdan, “Heat insulation ceramic materials based on refractory and clay refractory raw material of the Belarus republic,” Ogneupor. Tekhn. Keram., No. 6, 3 – 8 (2018).

Li Meiting, Luo Xudong, Zhang Guodomg, et al., “Effect of blowing-agent addition on the structure and properties of magnesia porous material,” Refract. Ind. Ceram., 58(7), 60 – 64 (2017). https://doi.org/10.1007/s11148-017-0054-7.

M. S. Manylov, S. V. Filimonov, O. N. Shornikova, et al., “Thermophysical properties of carbon-carbon materials based on graphite foam,” Refract. Ind. Ceram., 58(1), 113 – 116 (2017). https://doi.org/10.1007/s11148-017-0064-5.

V. N. Sokov, V. V. Sokov, and A. É. Beglyarov, “Theory and practice of creating composite chamotte heat-resistant heat insulation,” Internet-vestnik VolgGASU, Ser. Politem, No. 1(15). www.vestnik.vgasu.ru.

I. D. Kashcheev (editor) Refractories for Industrial units and Boilers: Handbook, in 2 Vol., Vol. 1 [in Russian], Intermet Inzhiniring, Moscow (2000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 5, pp. 126 – 131, May, 2021.

Rights and permissions

About this article

Cite this article

Urazaeva, E.M., Rumi, M.K., Nurmatov, S.P. et al. Influence of Production Factors on Lightweight Refractory Thermal Conductivity. Refract Ind Ceram 62, 299–304 (2021). https://doi.org/10.1007/s11148-021-00597-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-021-00597-2