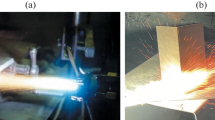

Results of comprehensive research on the use of exhaust gases from an internal combustion engine (ICE) as the source of hot hydrocarbons instead of propane-butane or natural gas to reduce oxidative processes are presented. Introduction of hot hydrocarbons in exhaust gases from an ICE is shown to reduce significantly the redox potential of a plasma-torch plasma jet with respect to the sprayed material. An experimental mobile multifunctional plasma installation is developed and enables air-plasma spraying and melting of applied wear-resistant coatings. In this case, the exhaust gases from an ICE are used as the plasma-forming gas.

Similar content being viewed by others

References

V. S. Loskutov, V. M. Rogozhin, and A. F. Puzryakov, “Plasma spraying as a technological method for treating materials,” Tr. MVTU, No. 237, No. 1, 3 – 27 (1977).

V. V. Kudinov and V. M. Ivanov, Plasma Spraying of Refractory Coatings [in Russian], Mashinostroenie, Moscow (1981).

A. Hasui and O. Morigaki, Surfacing and Spraying [translated from Japanese by V. N. Popov], V. S. Stepin and N. G. Shesterkin (eds.), Mashinostroenie, Moscow (1985).

V. V. Kudinov, P. Yu. Pekshev, V. E. Belashchenko, et al., Plasma Deposition of Coatings [in Russian], Nauka, Moscow (1990).

V. V. Kudinov and G. V. Bobrov, Deposition of Coatings by Spraying. Theory, Technology, and Equipment [in Russian], Metallurgiya, Moscow (1992).

A. I. Sidorov and S. V. Kartsev, “Effectiveness of plasma spraying followed by melting,” Mekh. Elektrif. Sel’sk. Khoz., No. 12, 20 – 23 (2000).

A. F. Puzryakov, Theoretical Bases of Plasma Spraying Technology [in Russian], Izd. MGTU im. N. E. Baumana, Moscow (2008).

I. N. Kravchenko, Yu. A. Kuznetsov, A. V. Kolomeichenko, and S. V. Kartsev, “Method for plasma deposition of antifriction wear-resistant coatings on titanium alloys,” Svar. Proizvod., No. 11, 42 – 45 (2019).

I. N. Kravchenko and S. V. Kartsev, Highly Effective Resource- saving Plasma Technologies for Depositing Protective Coatings, Scientific-Technical Collection. No. 10, Izd. BTU pri Spetsstroe Rossii, Balashikha, 87 – 94 (2005).

V. I. Kalita and D. I. Komlev, Plasma Coatings with Nanocrystalline and Amorphous Structures [in Russian], Lider M, Moscow (2008).

N. A. Sosnin, S. A. Ermakov, and P. A. Topolyanskii, Plasma Technologies. Handbook for Engineers [in Russian], Izd. Politekhn. Univ., St. Petersburg (2013).

I. N. Kravchenko, M. N. Erofeev, and M. A. Glinskii, “Promising directions for research and use of plasma technologies in mechanical engineering,” in: Tribology — Mechanical Engineering: Proceedings of the XIIth International Scientific-Technical Conference Dedicated to the 80th Anniversary of IMASH RAN [in Russian], Inst. Komp’yuternykh Issledovanii, Moscow, 253 – 256 (2018).

I. N. Kravchenko, M. A. Glinskii, S. V. Kartsev, et al., Resource- conserving Plasma Technologies for Repairing Reprocessing Equipment [in Russian], INFRA-M, Moscow (2020).

M. F. Zhukov, V. Ya. Smolyakov, and B. A. Uryukov, Electric- arc Gas Heaters (Plasmotrons) [in Russian], Nauka, Moscow (1973).

A. V. Donskoi and V. S. Klubnikin, Electroplasma Installations in Mechanical Engineering [in Russian], Mashinostroenie, Leningrad (1979).

A. S. Koroteev, V. M. Mironov, and Yu. S. Svirchuk, Plasma Torches: Designs, Characteristics, Calculations [in Russian], Mashinostroenie, Moscow (1993).

S. S. Samotugin, I. I. Pirch, and V. A. Mazur, “Optimizing the design of plasma torches for surface hardening of materials,” Svar. Proizvod., No. 12, 32 – 35 (2002).

V. A. Okovityi, A. I. Shevtsov, O. G. Devoino, and V. V. Okovityi, Rep. Belarus Pat. 14,906, IPC C23C4 / 04, “Plasma torch for coating deposition,” Oct. 30, 2011.

Yu. S. Bogdanov, “Arc plasma torch for deposition and its potential industrial use,” Vestn. Polots. Gos. Univ., Ser. B: Prikl. Nauki, No. 2, 155 – 158 (2010).

S. S. Samotugin and V. A. Gagarin, “Principles for improving plasmotron construction for surface hardening of machine slideways,” Vestn. Priazov. Gos. Tekh. Univ., No. 26, 168 – 174 (2013).

S. V. Anakhov, Yu. A. Pykin, and A. V. Matushkin, “Methods for calculating and designing plasmotrons for metal cutting,” Svar. Proizvod., No. 4, 22 – 28 (2019).

S. V. Kartsev, I. N. Kravchenko, and V. Yu. Gladkov, “Mobile plasma installation for deposition of wear-resistant coatings,” in: Technologies for Repair, Restoration, Strengthening, and Renewal of Machines, Mechanisms, Equipment, and Metal Constructions [in Russian], SPBPU, St. Petersburg, 215 – 220 (2004).

I. N. Kravchenko, S. V. Kartsev, and V. Yu. Gladkov, “Mobile plasma installation,” ZhKKh Stroitel‘stvo, No. 3, 58 (2005).

S. V. Kartsev, I. N. Kravchenko, and A. Yu. Gurtsiev, RU Pat. 66,341, IPC C23C4/00, “Installation for plasma spraying,” Sept. 10, 2007; Appl. No. 2007113494/22; Apr. 11, 2007; Byull. No. 25.

S. V. Kartsev, RU Pat. 92,238, IPC H01J1/02, “Plasmotron for plasma melting,” Mar. 10, 2010; Appl. No. 2009123241/22, Jun. 18, 2009; Byull., No. 7.

S. V. Kartsev and V. N. Varlamov, “Composition of exhaust gases from an internal combustion engine,” in: Collection of Scientific Works. No. 14, Izd. VTU pri Spetsstroe Rossii, Balashikha, 142 – 145 (2007).

S. V. Kartsev, I. N. Kravchenko, and V. N. Varlamov, “ICE as a source of hot hydrocarbons for plasma installations for hardening and restoring machine parts,” Remont Vosstanov. Moderniz., No. 1, 11 – 13 (2008).

V. M. Amosov, B. A. Karelin, and V. V. Kubyshkin, Electrode Materials Based on Refractory Alloys [in Russian], Metallurgiya, Moscow (1976).

L. M. Yakimenko, Electrode Materials in Applied Electrochemistry [in Russian], Khimiya, Moscow (1977).

B. S. Gavryushenko and A. V. Pustogarov, “Study of plasmotron electrodes,” in: Electrode Processes and Erosion: Collection [in Russian], Inst. Teplofiz. Sib. Otd. Akad. Nauk SSSR, Novosibirsk, 85 – 122 (1977).

M. F. Zhukov, I. M. Zasypkin, A. N. Timoshevskii, et al., Electric-arc Thermal Plasma Generators [in Russian], Nauka, Sib. Otd. Ross. Akad. Nauk, Novosibirsk (1999).

S. V. Kartsev, “Operational characteristics of plasmotron electrodes of a plasma installation,” Remont Vosstanov. Moderniz., No. 7, 29 – 31 (2008).

V. E. Kuznetsov, A. A. Kiselev, R. V. Ovchinnikov, and Yu. D. Dudnik, “Electrodes of one-phase alternating current plasmotrons and materials for their fabrication,” Nauchno-Tekh. Vedomosti SPbGPU. Fiz.-Mat. Nauki, No. 2 (146), 100 – 104 (2012).

M. F. Zhukov, A. S. Anypakov, and G.-N. B. Dandaron, Electrode Processes and Erosion of Plasmotron Electrodes: Collection [in Russian], Inst. Teplofiz. Sib. Otd. Akad. Nauk SSSR, Novosibirsk (1977).

A. D. Rychkov and V. V. Salomatov, “Mathematical modeling of electrode erosion processes in electric-arc generators of low-temperature plasma,” Izv. Tomsk. Politekh. Univ., 305(2), 61 – 66 (2002).

D. I. Subbotin, V. E. Kuznetsov, A. I. Litvyakova, et al., “Study of alternating current plasmotron copper electrode erosion products,” Zh. Tekh Fiz., 87(11), 1637 – 1640 (2017). DOI: https://doi.org/10.21883/JTF.2017.11.45122.2064.

V. E. Kuznetsov, A. A. Safronov, V. N. Shiryaev, et al., “Investigation of the parameters of electrode erosion in direct and alternating current plasma torches,” Prikl. Fiz., No. 3, 24 – 30 (2019).

G. K. Klimenko and A. A. Lyapin, “Constructions of electric arc plasmotrons [electronic resource], Izd. MGTU im. N. E. Baumana, Moscow (2011).

V. L. Dzyuba, K. A. Korsunov, and V. S. Gavrysh, “Improved operating effectiveness of a plasmotron for spraying,” in: Modern Technologies, Materials, Machines, and Equipment [in Russian], MGTU, Mogilev, pp. 48, 49 (2002).

S. E. Vinogradov, V. V. Rybin, F. G. Rutberg, et al., “Investigation of wear mechanisms of plasmotron electrodes,” Vopr. Materialoved., No. 2, 52 – 59 (2002).

V. E. Kuznetsov, R. V. Ovchinnikov, V. A. Spodobin, et al., “Investigation of method of rod electrode lifetime increase and time of continuous operation of high-voltage electric-arc alternating current plasma torches with power from 5 to 50 kW,” Izv. Vyssh. Uchebn. Zaved., Fiz., 50(9 – 2), 206 – 209 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 7, pp. 51 – 56, July, 2020.

Rights and permissions

About this article

Cite this article

Kravchenko, I.N., Kartsev, S.V. & Kuznetsov, Y.A. Use of Hot Hydrocarbons in a Plasma Installation for Application of Wear-Resistant Coatings. Refract Ind Ceram 61, 399–403 (2020). https://doi.org/10.1007/s11148-020-00492-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-020-00492-2