Abstract

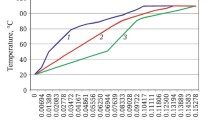

The Stal’proekt Institute has developed state-of-the-art plants for drying and high-temperature heating of steel-teeming ladles. Two new plants for drying tundish ladle lining have been designed for machine No. 6 for continuous billet casting at the Oskol’skii Electrometallurgical Works. Plants for drying and heating 30-ton teeming ladles to a temperature of 800°C and for high-temperature heating of ladle lining (1200°C) have been designed for a currently constructed metallurgical works. All these plants recover flue gas heat and use it for heating air supplied for combustion, thus decreasing the consumption of fuel. The process of drying and heating of lining is analyzed using a mathematical model developed at the institute. The plants are equipped with automatic control systems controlling the temperature schedule of drying and heating the lining. The specified plants ensure cost-effective operation in an automatic mode

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

__________

Translated from Novye Ogneupory, No. 10, pp. 21–25, October, 2006.

Rights and permissions

About this article

Cite this article

Chaikin, B.S., Mar’yanchik, G.E., Panov, E.M. et al. State-of-the-art plants for drying and high-temperature heating of ladles. Refract Ind Ceram 47, 283–287 (2006). https://doi.org/10.1007/s11148-006-0109-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11148-006-0109-7