Abstract

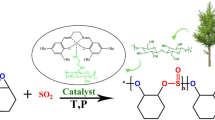

SO4 2−/TiO2 solid acid catalyst, a kind of green catalyst, was introduced as an alternative of sulfuric acid in the synthesis of cellulose acetate (CA). It has been investigated that SO4 2−/TiO2 presented prominent catalytic activity during this process. The degree of polymerization of CA obtained using SO4 2−/TiO2 catalyst was 1.7 times higher than that using H2SO4, which could influence the mechanical properties of CA considerably. In addition, the SO4 2−/TiO2 solid acid catalyst exhibited perfect reusability in the acetic acid system for cellulose acetylation, with traces of SO4 2− leached during the reaction confirmed by NH3-TPD. It was investigated by XRD that the polymorphic of catalyst transformed from amorphous TiO2 to anatase TiO2 with the increase of calcination temperature and prolongation of calcination time, improving the catalytic activity of SO4 2−/TiO2 solid acid catalyst. The higher crystallinity it had, the better catalytic activity the SO4 2−/TiO2 catalyst exhibited. However, due to the decomposition of SO4 2− on the catalyst surface, confirmed by TG-MS analysis, the catalytic activity of SO4 2−/TiO2 catalyst decreased sharply when the calcination temperature was above 550 °C. The structure of SO4 2−/TiO2 solid acid catalyst has been investigated by FT-IR, and it can be confirmed that the SO4 2− group was bidentate coordinated with TiO2.

Similar content being viewed by others

References

Zhang Y, Yin C, Zhang Y, Wu H (2013) Synthesis and characterization of cellulose carbamate from wood pulp, assisted by supercritical carbon dioxide. Bioresources 8(1):1398–1408

Chen H-Z, Wang N, Liu L-Y (2012) Regenerated cellulose membrane prepared with ionic liquid 1-butyl-3-methylimidazolium chloride as solvent using wheat straw. J Chem Technol Biotechnol 87(12):1634–1640

Rodrigues Filho G, Monteiro DS, da Silva Meireles C, de Assunção RMN, Cerqueira DA, Barud HS, Ribeiro SJL, Messadeq Y (2008) Synthesis and characterization of cellulose acetate produced from recycled newspaper. Carbohydr Polym 73(1):74–82

Akkaya A (2013) Covalent immobilization of urease to modified ethyl cellulose. Fibers Polym 14(1):22–27

Doh SJ, Lee JY, Lim DY, Im JN (2013) Manufacturing and analyses of wet-laid nonwoven consisting of carboxymethyl cellulose fibers. Fibers Polym 14(12):2176–2184

Kim SS, Ryoo KY, Lim J, Seo B, Lee J (2013) Cellulose fibers coated with m-aramid for medical applications. Fibers Polym 14(3):409–414

Satgé C, Granet R, Verneuil B, Branland P, Krausz P (2004) Synthesis and properties of biodegradable plastic films obtained by microwave-assisted cellulose acylation in homogeneous phase. Comptes Rendus Chim 7(2):135–142

Cao Y, Wu J, Meng T, Zhang J, He J, Li H, Zhang Y (2007) Acetone-soluble cellulose acetates prepared by one-step homogeneous acetylation of cornhusk cellulose in an ionic liquid 1-allyl-3-methylimidazolium chloride (AmimCl). Carbohydr Polym 69(4):665–672

Bocahut A, Delannoy J-Y, Vergelati C, Mazeau K (2014) Conformational analysis of cellulose acetate in the dense amorphous state. Cellulose 21(6):3897–3912

Law RC (2004) 5. Applications of cellulose acetate 5.1 cellulose acetate in textile application. In: Macromol symp, vol 208, No. 1. Wiley, New York, pp 255–266

Rustemeyer P (2004) 5.2 CA filter tow for cigarette filters. In: Macromol symp, vol 208, No. 1. Wiley, New York, pp 267–292

Carollo P, Grospietro B (2004) 5.5 Plastic materials. In: Macromol symp, vol 208, No. 1. Wiley, New York, pp 335–352

Shibata T (2004) 5.6 Cellulose acetate in separation technology. In: Macromol symp, vol 208, No. 1. Wiley, New York, pp 353–370

Fink H-P, Weigel P, Purz HJ, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO-solutions. Prog Polym Sci 26(9):1473–1524

Li J, Zhang L-P, Peng F, Bian J, Yuan T-Q, Xu F, Sun R-C (2009) Microwave-assisted solvent-free acetylation of cellulose with acetic anhydride in the presence of iodine as a catalyst. Molecules 14(9):3551–3566

Steinmeier H (2004) 3. Acetate manufacturing, process and technology 3.1 chemistry of cellulose acetylation. In: Macromol symp, vol 208, No. 1. Wiley, New York, pp 49–60

Hummel A (2004) 3.2 Industrial processes. In: Macromol symp, vol 208, No. 1. Wiley, New York, pp 61–80

Meng C, Lu H, Cao G-P, Yao C-W, Liu Y, Zhang Q-M, Bai Y-B, Wang H (2015) Activation of cellulose by supercritical tetrafluoroethane and its application in synthesis of cellulose acetate. Ind Eng Chem Res 54(48):12204–12213

Chen JH, Xu JK, Wang K, Cao XF, Sun RC (2016) Cellulose acetate fibers prepared from different raw materials with rapid synthesis method. Carbohydr Polym 137:685–692

Cheng HN, Dowd MK, Selling GW, Biswas A (2010) Synthesis of cellulose acetate from cotton byproducts. Carbohydr Polym 80(2):450–453

Cheng HN, Dowd MK, Shogren RL, Biswas A (2011) Conversion of cotton byproducts to mixed cellulose esters. Carbohydr Polym 86(3):1130–1136

Biswas A, Shogren RL, Willett JL (2005) Solvent-free process to esterify polysaccharides. Biomacromolecules 6(4):1843–1845

Dalai AK, Sethuraman R, Katikaneni SPR, Idem RO (1998) Synthesis and characterization of sulfated titania solid acid catalysts. Ind Eng Chem Res 37(10):3869–3878

García E, Volpe MA, Ferreira ML, Rueda E (2003) A discussion of a mechanism for isomerization of n-butane on sulfated zirconia. J Mol Catal A Chem 201(1–2):263–281

Li X, Nagaoka K, Simon LJ, Olindo R, Lercher JA, Hofmann A, Sauer J (2005) Oxidative activation of n-butane on sulfated zirconia. J Am Chem Soc 127(46):16159–16166

Jung SM, Grange P (2000) Characterization and reactivity of pure TiO2–SO4 2− SCR catalyst: influence of SO4 2− content. Catal Today 59(3–4):305–312

Ortiz-Islas E, Gomez R, Lopez T, Navarrete J, Aguilar DH, Quintana P (2005) Effect of the crystallite size in the structural and textural properties of sulfated and phosphated titania. Appl Surf Sci 252(3):807–812

Ortiz-Islas E, López T, Navarrete J, Bokhimi X, Gómez R (2005) High selectivity to isopropyl ether over sulfated titania in the isopropanol decomposition. J Mol Catal A Chem 228(1–2):345–350

Waqif M, Bachelier J, Saur O, Lavalley J-C (1992) Acidic properties and stability of sulfate-promoted metal oxides. J Mol Catal 72(1):127–138

Mantilla A, Ferrat G, López-Ortega A, Romero E, Tzompantzi F, Torres M, Ortíz-Islas E, Gómez R (2005) Catalytic behavior of sulfated TiO2 in light olefins oligomerization. J Mol Catal A Chem 228(1):333–338

Tian C-X, Yang Y, Pu H (2011) Effect of calcination temperature on porous titania prepared from industrial titanyl sulfate solution. Appl Surf Sci 257(20):8391–8395

Yan M, Chen F, Zhang J, Anpo M (2005) Preparation of controllable crystalline titania and study on the photocatalytic properties. J Phys Chem B 109(18):8673–8678

Yang Q, Xie C, Xu Z, Gao Z, Du Y (2005) Synthesis of highly active sulfate-promoted rutile titania nanoparticles with a response to visible light. J Phys Chem B 109(12):5554–5560

Hu Y, Guo B, Fu Y, Ren Y, Tang G, Chen X, Yue B, He H (2015) Facet-dependent acidic and catalytic properties of sulfated titania solid superacids. Chem Commun 51(75):14219–14222

Zhao H, Jiang P, Dong Y, Huang M, Liu B (2014) A high-surface-area mesoporous sulfated nano-titania solid superacid catalyst with exposed (101) facets for esterification: facile preparation and catalytic performance. New J Chem 38(9):4541–4548

Zhao H, Jiang P, Dong Y, Huang M, Liu B (2014) Effects of morphology and crystal phase of sulfated nano-titania solid acids on catalytic esterification. Reac Kinet Mech Cat 113(2):445–458

Ropero-Vega JL, Aldana-Pérez A, Gómez R, Niño-Gómez ME (2010) Sulfated titania [TiO2/SO4 2−]: a very active solid acid catalyst for the esterification of free fatty acids with ethanol. Appl Catal A Gen 379(1–2):24–29

Shi W, Li J (2014) A deactivation mechanism of sulfated titania in the esterification of acetic acid and n-butanol. Reac Kinet Mech Cat 111(1):215–233

Leng Y, Zhang Y, Huang C (2013) Catalytic conversion of cellulose to cellulose acetate propionate (CAP) over SO4 2−/ZrO2 solid acid catalyst. Bull Korean Chem Soc 34(4):1160–1164

Yan L, Li W, Qi Z, Liu S (2006) Solvent-free synthesis of cellulose acetate by solid superacid catalysis. J Polym Res 13(5):375–378

Li X-K, Lu H, Guo W-Z, Cao G-P, Liu H-L, Shi Y-H (2015) Reaction kinetics and mechanism of catalyzed hydrolysis of waste pet using solid acid catalyst in supercritical CO2. AIChE J 61(1):200–214

Luo J, Sun Y (2006) Acetylation of cellulose using recyclable polymeric catalysts. J Appl Polym Sci 100(4):3288–3296

Samios E, Dart RK, Dawkins JV (1997) Preparation, characterization and biodegradation studies on cellulose acetates with varying degrees of substitution. Polymer 38(12):3045–3054

Regiani AM, Frollini E, Marson GA, Arantes GM, El Seoud OA (1999) Some aspects of acylation of cellulose under homogeneous solution conditions. J Polym Sci Part A Polym Chem 37(9):1357–1363

Bokhimi X, Morales A, Ortíz E, López T, Gómez R, Navarrete J (2004) Sulfate ions in titania polymorphs. J Sol Gel Sci Technol 29(1):31–40

Acknowledgements

The authors gratefully acknowledge the financial support provided by Undergraduate Training Programs for Innovation and Entrepreneurship (X15024).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, C., Cao, GP., Li, XK. et al. Structure of the SO4 2−/TiO2 solid acid catalyst and its catalytic activity in cellulose acetylation. Reac Kinet Mech Cat 121, 719–734 (2017). https://doi.org/10.1007/s11144-017-1165-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-017-1165-3