Abstract

The transformations of styrene dimers at 753 K over catalysts possessing Lewis acid centers as well as weak Brønsted sites of HO > −2.2 (γ-Al2O3); Lewis acid, weak Brønsted sites of −3.5 < HO ≤ −2.2 and redox centers (γ-Al2O3–Cr); strong Brønsted sites of −14 < HO ≤ −3.5 (SiO2–Al2O3(13 %)), strong Brønsted sites of 14 < HO ≤ −3.5 and redox centers (SiO2–Al2O3(13 %)–Cr) have been studied. It was established that the following surface groups are responsible for the catalytic activity in the transformation of styrene dimers. γ-Al2O3: OH group adjacent to Al3+ cation (alkenyl chain protonation) and Al3+ (allylic anion generation); γ-Al2O3–Cr: Brønsted acid centers originating from chromium ions at high oxidation states (alkenyl chain protonation) and Cr3+ redox sites (allylic cation generation); SiO2–Al2O3(13 %)–Cr: Brønsted acid centers of silica–alumina (alkenyl chain and aromatic ring protonation) and Cr3+ redox sites (allylic cation generation). The protonation of styrene dimer at the alkenyl chain leads to β-cleavage to toluene and α-methylstyrene as well as to styrene and ethylbenzene. The allylic species formed react to the different styrene dimer isomers and through diphenylbutadiene intermediate to coke. The use of methylcyclohexane as solvent for the styrene dimers in the presence of chromium containing catalysts results in the aromatization reaction leading to toluene and hydrogen. The presence of the later reactant in the system causes styrene and α-methylstyrene hydrogenation to ethylbenzene and cumene.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Chemical recycling is considered as an efficient method of processing polystyrene (PS) wastes [1]. It is based on the catalytic conversion of wastes to monomer or other compounds, which can be useful in the chemical syntheses or utilized as components of fuels. We showed in our works [2, 3] how PS reacts in the presence of catalysts of the nature of Brønsted acids (silica–aluminas, sulfated alumina) and bases (alumina and silica–alumina dotted with NaOH). At high reaction temperature (750 K), PS undergoes fast depolymerization to form volatile oligomers, mostly dimers, which react in a sequence of consecutive transformations (Scheme 1).

Styrene dimers such as diphenylbutenes undergo protonation both in the alkyl chain and in the aromatic ring in the presence of acid catalysts. In the first case, β-cleavage of the alkyl chain and a hydrogen transfer reaction result in the formation of toluene, α-methylstyrene and cumene as well as styrene and ethylbenzene, while internal alkylation leads to phenylmethylindane. In the second case, benzene, methylindane, naphthalene and coke (dealkylation, hydrogen transfer, oligomerization) are the reaction products. In the presence of base catalysts, styrene dimers undergo deprotonation. The anions formed decompose to the monomer i.e., styrene.

The interaction of PS or styrene dimers with Brønsted acids or bases leading to their decomposition has been described extensively. This consists of an initial step of proton addition or elimination to/from reacting species. On the other hand, the activation of styrene dimers by Lewis acid centers or redox sites has up till now not been unambiguously proposed. It can be expected to be similar to the transformation of the aliphatic skeleton of styrene dimers i.e., butene during isomerization. Formally, such activation can be attributed to the following specific cases:

-

(a)

The attachment of a double bond of an alkene to a Lewis center forming a carbenium ion. Such interaction was postulated for Zr4+ and methylenecyclohexane during isomerization over zirconia [4] and for alkene activation by Al2Cl7 −, the component of an ionic liquid.

-

(b)

The elimination of a hydride anion from the alkene on a Lewis acid center to obtain an allylic cation. Such step is proposed as the initiation of coke formation during catalytic cracking [5].

-

(c)

The attachment of the aromatic ring to a Lewis acid site. This reaction step was proposed as the beginning of coke formation during catalytic cracking in the presence of silica–alumina [6].

Moreover, in the particular case of alumina it is suggested that:

-

(d)

The elimination of a proton from an alkene on the Lewis acid-Lewis base pair: Al3+–O2− to obtain an allylic anion [7–9].

-

(e)

The activation of OH groups adjacent to Lewis acid centers in order to protonate an alkene. This type of interaction was proposed to explain butene isomerization at elevated temperatures [9].

Redox centers activate alkenes in two consecutive steps. In the first step, a proton is detached from the allylic position in butene and then the resulting anion is oxidized to allylic cation [8] in the second step. Thus, it can be concluded that Lewis acid and redox centers activate styrene dimers forming different ionic and radical intermediates, which could influence the transformation of styrene dimers into diverse products.

The aim of our work was to study the transformation of styrene dimers in the presence of catalysts of acid and redox nature. These were γ-Al2O3 (strong Lewis and weak Brønsted acid [9, 10]) and SiO2–Al2O3(13 %) (strong Brønsted acid [10]) dotted with chromium ions. This set of catalysts should allow the study of styrene dimer transformation over the catalysts whose nature change continuously from acidic: protic or aprotic to redox. Moreover, the application of a redox catalyst and a solution of styrene dimers in heptane and methylcyclohexane should allow the investigation of the influence of the hydrogen formed in situ during transformation. It is expected that at least one of the solvents i.e., methylcyclohexane would be an efficient hydrogen donor.

The acid and redox properties of the catalysts were studied using the test reaction method with cumene as a reactant at 753 K. The composition of products is indicative of the presence of specific active centers i.e., benzene and diisopropylbenzenes for Brønsted acid sites [11], ethyltoluene and ethylbenzene for Lewis acid centers [11] and α-methylstyrene for redox ones [12, 13]. Transformation of α-methylstyrene, styrene and tert-butylbenzene at 303 K was used for the evaluation of the strength of acid sites. In our previous work [3], we reported that these compounds react at ambient temperature in a batch reactor if the acid strength of the catalyst exceeds −2.2, −3.5 and −14.0 units of HO, and can be used to evaluation of acid strength of solids.

Experimental

Catalysts

The following solids were used as catalysts or supports: SiO2 (ABCR Karlsruhe, SBET 266 m2/g), γ-Al2O3 (ABCR Karlsruhe, SBET 206 m2/g) and silica–alumina: 87 % SiO2–13 % Al2O3 (Ventron GmBH, SBET 392 m2/g). MgO (SBET 100 m2/g) was synthesized from magnesium hydroxide obtained by precipitation from an aqueous solution of magnesium nitrate with NH4OH. The precipitate was dried at 313, 353 and 393 K for 24 h and calcined at 873 K in a stream of dry air for an additional 24 h. γ-Al2O3–Cr and SiO2–Al2O3(13 %)–Cr catalysts with a deposition of 0.5, 1.0, 2.0, 3.0 and 5 wt% of Cr were obtained by incipient wetness impregnation method with chromium(III) nitrate nonahydrate as a precursor. The preparations were dried at 333 and 383 K for 24 h and then calcined at 753 K in a stream of dry air for 24 h. 1.02–1.20 mm grain fraction of all catalysts was used for catalytic measurements.

Synthesis of styrene dimers

Styrene dimers were prepared according to the procedure described elsewhere [2]. The resulting product contained polystyrene dimers (91.2 wt%), trimers (7.8 wt%) and tetramers (1.0 wt%). The product was diluted with n-heptane or methylcyclohexane in a 1:1 molar proportion in order to obtain the reaction substrate.

Cumene, styrene dimers reactions

The reactions were performed in a flow reactor. The catalyst (2 cm3) was placed in the reactor and heated for 24 h at 753 K in a stream of dry air. After catalyst activation, the reactor was cooled to the desired temperature (from 473 to 753 K) and the reactant fed to it with an infusion pump at 3.6 cm3/h for 60 min. Styrene dimers were fed into reactor as heptane and methylcyclohexane mixtures (1:1 mol). Trans,trans-1,4-diphenyl-1,3-butadiene was also used as reactant as a solution in heptane (1.5 wt%).

Acid strength measurements

Before the reaction, the catalyst sample (0.5 g) was placed in a glass batch reactor (76 cm3) connected to a vacuum/dry air line and calcined at 753 K for 20 h in a stream of dry air. The reactor was cooled to the required temperature, the catalyst was transferred in the stream of dry air into a glass vial (5 cm3) equipped with a screw closure and then the substrates (1 cm3) was injected. The products were analyzed after 20 h of the reaction time (temperature: 303 K, Mini Incubator 4,010, GLF; shaking: 60 rpm, Shaker DOS-20S Elmi Ltd).

Materials

All organic reactants and Cr(NO3)3·9H2O were supplied by Aldrich.

Analysis

The obtained reaction products were analyzed in a GC (Agilent 6890 N with FID detector) equipped with a 30 m HP5 capillary column (I.D. 0.32 mm, df 0.25 μm, temperature 343 K (5 min), to 543 K at 3 K/min).

Results

Acid and redox properties: transformation of cumene

γ-Al2O3–Cr

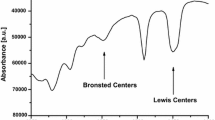

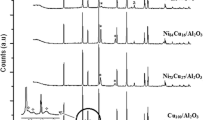

The investigated alumina did not possess any distinctive acid sites, especially of Brønsted type, nor redox properties. Cumene transformation products typical for the activity of the mentioned centers [11–13] i.e., benzene and α-methylstyrene (Fig. 1) appeared in very low quantities: 0.3 and 0.9 %. Similarly, the conversion to ethylbenzene and ethyltoluene as a result of from Lewis acid center activity was also low (0.3 and 0.1 %). The introduction of chromium ions on alumina surface increased the acidity of the system slightly. The conversion of cumene to benzene increased to 1.0 % for γ-Al2O3–Cr(5 %). The redox properties were also found to be considerably enhanced because cumene to α-methylstyrene conversion attained a level of 13 % for the γ-Al2O3–Cr(5 %) catalyst.

Heptane and methylcyclohexane transformation

The redox properties of γ-Al2O3–Cr catalysts can be also observed when heptane and methylcyclohexane—solvents of styrene dimers were used as reactants. In both cases, toluene was the main component of the reaction products (Fig. 1). An increase in chromium concentration on the alumina surface lead to a rise in toluene formation.

Al2O3–SiO2(13 %)–Cr

Pure silica–alumina is a solid Brønsted acid, which converted cumene into benzene with selectivity as high as 94 %. The presence of 5 % chromium ions in the sample caused a decrease in acid centers concentration, which resulted in a decrease in benzene formation from 55 to 32 % (Fig. 2). At the same time, α-methylstyrene appeared among reaction products attaining 4 % conversion level for Al2O3–SiO2(13 %)–Cr(5 %).

Acid strength

Acid strength measurements were performed for two catalysts i.e., γ-Al2O3–Cr(5 %) and Al2O3–SiO2(13 %)–Cr(5 %). The results were compared with these that have been previously published [3] for pure carriers (Table 1).

The presence of chromium ions did not change the acid strength of acid centers of Al2O3–SiO2(13 %), which is estimated at −14 < HO ≤ −3.5 since the reactions of α-methylstyrene and styrene at 303 K took place. On the other hand, in the case of γ-Al2O3–Cr system, the appearance of new Brønsted sites (−3.5 < HO ≤ −2.2) were observed, which were not initially present in the alumina carrier (α-methylstyrene began to react at 303 K).

Thermal transformation of styrene and styrene dimers

The thermal transformation of equimolar solutions of styrene dimers in heptane and methylcyclohexane was studied over an inert SiO2 bed instead of a catalyst in a flow system at 753 K. The results are gathered in Table 2.

In both cases, the main reaction products were styrene dimer isomers. The selectivity of this reaction pathway was 56 and 62 % for the reactions of heptane and methylcyclohexane solutions, respectively. Ethylbenzene, styrene, toluene and α-methylstyrene were also found among reaction products. The reaction performed with styrene as a substrate revealed that it does not undergo consecutive, thermal transformation.

Catalytic transformation of styrene dimers

γ-Al2O3–Cr

Different styrene dimer isomers were the primary products of styrene dimer transformation over alumina (Table 3). The selectivities observed for heptane and methylcyclohexane reactant solutions were 59 and 64 %, respectively. The other products were toluene, ethylbenzene, styrene, cumene and α-methylstyrene and small quantities of benzene (<0.5 %).

The presence of chromium ions on the alumina surface resulted mainly in a rise in styrene dimer conversion to ethylbenzene and cumene.

The reaction of 1,4-diphenylbutadiene, presumed transition product of polystyrene and styrene dimers transformation, over alumina was also studied. It was found that the main reaction product was coke (92.4 %). The other products were benzene (1.9 %), methylindene (1.3 %), and naphthalene (1.9 %).

SiO2–Al2O3(13 %)–Cr

Silica–alumina catalyzes the isomerization of styrene dimers as well as their decomposition to benzene, ethylbenzene, toluene and methyl derivatives of indane, indene and naphthalene (Table 4).

The introduction of chromium ions on the silica–alumina results in decrease in the conversion of styrene dimers to benzene and indane, indene and naphthalene derivatives, however, the increase in the yield of styrene dimer isomerization products was observed. Conversion to ethylbenzene practically does not change.

Discussion

Catalytic decomposition of polystyrene proceeds under mutual influence of two factors i.e., high temperature and catalyst. The former factor causes the polymer decomposition to volatile oligomers, mainly dimers which undergo consecutive catalytic transformations. These reactions are usually initiated by Brønsted acid centers [14] or basic sites [15–17]. The action of Lewis acid and redox centers is less documented. In the presented work we used the well-known solid acids such as silica–alumina SiO2–Al2O3(13 %) and γ-Al2O3 whose properties were modified by the addition of chromium ions (1–5 wt%) to study styrene dimers transformation. The choice of catalysts should allow the examination how the transformation of Brønsted acid—the silica–alumina [10] and Lewis acid—alumina [10] into redox type catalysts—chromia containing silica–alumina and alumina, influence the reaction. Moreover, the use of heptane and methylcyclohexane, potential hydrogen donors, as solvents for styrene dimers should permit to examine the influence of hydrogen on the transformation. The presence of acid and redox centers was ascertained using the test reaction method. On the basis of cumene transformation at 753 K, it was found that Brønsted acid centers concentration of the silica–alumina diminishes with an increase in the quantity of chromium ions introduced (Fig. 1). It is interesting that the introduction of 5 % of Cr did not eliminate acid sites completely but merely reduced their concentration. The acid strength of these sites, estimated by means of the results of test reactions of α-methylstyrene, styrene and tert-butylbenzene at 303 K, did not change, either, it remaining at the level of 14.0 < HO ≤ −3.5 (Table 1). At the same time, new centers of redox type appeared on the silica–alumina surface, presumably chromium ions, able to dehydrogenate cumene to α-methylstyrene. In conclusion, the SiO2–Al2O3(13 %)–Cr system possesses both Brønsted acid as well as redox sites, whose concentration depends on the content of chromium ions. The introduction of chromium ions on alumina modified its surface in a different manner. Apart from redox sites, the new Brønsted acid centers appeared, which is exhibited in an increase in conversion of cumene to benzene from 0.3 % for alumina to 1.6 % for γ-Al2O3–Cr(5 %). The strength of the acid sites was not high and was estimated at −3.5 < HO ≤ −2.2. These centers were able to protonate α-methylstyrene, but not to transfer a proton to a styrene molecule at 303 K. The selectivity of cumene transformation to benzene and α-methylstyrene, which was 9.3 and 72.6 %, indicates that this catalyst possesses more dehydrogenating power than acidic character. This is also confirmed by the results of the transformation of heptane and methylcyclohexane, styrene dimer solvents (Fig. 1). An increase in the concentration of chromium ions leads to a rise in conversion to the dehydrogenating product i.e., toluene. The higher yield observed for methylcyclohexane suggests that this compound could be an effective source of hydrogen in the reacting system.

The thermal transformation of styrene dimers solutions were studied in order to examine non-catalytic reaction proceeding through radical intermediates. The main products observed i.e., toluene and α-methylstyrene as well as styrene and ethylbenzene (decomposition) and different diphenylbutenes (isomerization) resulted C–C and C–H bond cleavages in the aliphatic chain of styrene dimer (Scheme 2).

Hydrogen needed for the formation of α-methylstyrene, ethylbenzene, styrene and cumene was obtained in chain transfer reactions. The obtained results indicate that styrene dimers solvents did not take part in the transformation. The ratio of styrene dimer conversion to toluene and α-methylstyrene observed for heptane and methylcyclohexane solutions were 0.78 and 0.74. These values are lower than expected (close to unity) and indicate that toluene was not formed additionally during thermal dehydrogenation of the applied solvents. Moreover, the low ethylbenzene to styrene ratio point to hydrogen deficiency in the reacting system.

The γ-Al2O3–Cr catalytic system

Over γ-Al2O3, solutions of styrene dimers underwent mainly isomerization leading to different diphenylbutenes and decomposition reactions to obtain toluene, α-methylstyrene, ethylbenzene and styrene. By comparing the results of thermal and catalytic transformations, it can be observed that cumene is formed in the latter reaction. It is probably due to consecutive hydrogenation of α-methylstyrene. The ratio of the conversion of styrene dimers to toluene as against the sum of conversions to α-methylstyrene and cumene (T/αMSt+C), which should be equal to 1 according to the mass balance of the reaction, was found to be 0.83 and 0.81 for the dimers dissolved in heptane and methylcyclohexane, respectively. The toluene deficiency with respect to α-methylstyrene and cumene indicates that hydrogen did not originate from the solvents. Similarly, ethylbenzene to styrene ratio was close to unity and much higher than in the case of thermal conversion of styrene dimers which indicates that the catalytic transformation proceeds according to a different mechanism. The interaction of a styrene dimer possessing phenyl di-substituted butene aliphatic chain with alumina should be similar to that proposed for only butene. It was postulated that Al3+−O2− site of γ-Al2O3 eliminates proton from the alkene forming an OH group and a π-allylic carboanion bonded to Al3+ cation (Lewis acid center) [7–9]. It is also claimed that OH groups located close to Lewis acid centers, inactive in ambient temperature, are able to protonate a butene molecule at higher temperatures [9]. If the activation of a styrene dimer takes place with the formation of a π-allylic anion then the reaction results should be similar to those observed for basic catalysts such as MgO or SiO2–Al2O3 containing above 12 % of NaOH [2]. On the other hand, if weak Brønsted acid sites are active then, the product composition should be similar to that obtained from silica–alumina whose Brønsted acid centers have been partly neutralized. We have shown [2] that the introduction of sodium ions (4 % NaOH) on silica–alumina eliminates strong protic sites responsible for cumene dealkylation at 753 K leaving weaker species, which can only protonate the double bond in the alkyl chain of a styrene dimer. The results of styrene dimers reactions expressed as respective selectivities over γ-Al2O3, SiO2–Al2O3 dotted with 4 and 18 % of NaOH (taken from [2]) as well as MgO are shown in Fig. 3.

The products composition observed for two typical basic catalysts i.e., MgO and SiO2–Al2O3(54 %)–Na(18 %) is clearly different than that detected for γ-Al2O3. The main differences can be observed for toluene, ethylbenzene, cumene, α-methylstyrene and for most isomeric dimers. On the other hand, the products selectivities for alumina and SiO2–Al2O3(54 %)–Na(4 %) are similar, so it can be inferred that styrene dimers react in a similar manner over alumina and weak Brønsted acids. In such cases, the only transformation observed resulted from proton addition to unsaturated dimer alkyl chain. The reactions leading to the formation of indane, indene and naphthalene derivatives do not take place since strong protic sites able to protonate the aromatic ring are necessary for their initiation. The probability of such reaction mechanism is further supported by the observation that alumina, generally presumed to possess Lewis acid and weak Brønsted acid centers [18], transforms 2-butene to alkoxy species at elevated temperatures (>473 K) [19].

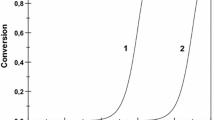

The introduction of chromium ions on alumina surface results in the formation of redox centers. These centers are able to eliminate a proton from the allylic position of the alkenyl chain in the styrene dimer and to oxidize the resulting allylic anion to a cation [8] for further transformation. Moreover, new Brønsted acid sites are also formed because of the activity of chromium ions. These sites, formed due to the presence of chromium ions in high oxidation state [20], possess an acid strength of −3.5 < HO ≤ −2.2 and catalyze cumene dealkylation and they are also able to transform the styrene dimer into respective carbocation. Thus, one can expect that the products of styrene dimer transformation over γ-Al2O3–Cr are obtained from allylic cation and diphenylbutyl cation intermediates. The transformation of styrene dimers transformation over γ-Al2O3–Cr leads to products whose distribution is in agreement with the mechanism involving alkenyl chain protonation proposed for γ-Al2O3. The differences observed in specific conversions are in the increasing yields of decomposition products i.e., styrene and ethylbenzene. This can be explained by the fact that the protic acidity of γ-Al2O3–Cr catalysts is higher than in undotted alumina. On the other hand the stepwise increase in the conversion of styrene dimers to ethylbenzene (Fig. 4), observed when chromium ions are introduced on alumina surface can result from the consecutive hydrogenation of decomposition product—styrene. In the case of alumina, ionic–type coking reaction is the source of hydrogen. It proceeds through π-allylic intermediates resulting from hydride anion abstraction by Lewis acid centers. After consecutive deprotonation, diphenylbutadiene is formed, which undergoes further transformation leading to the complex condensed polyaromatics as pyrene, benzofluoranthene and benzoperylene derivatives-coke and hydrogen. Such mechanism is generally accepted for coking reactions leading to catalyst decay in catalytic cracking [5, 21]. In order to verify the role of diphenylbutadiene in the coke formation reaction, the transformation of this compound was studied over alumina. It was found that 1,4-dipenylbutadiene (1.4 % heptane solution) formed mostly coke under the same reaction conditions. In the presence of the redox sites (of γ-Al2O3–Cr system), dehydrogenation reactions became faster which resulted in the increase of diphenylbutadiene production and thus a rise of hydrogen quantity in the system. At the same time, the reactions of the applied solvents to toluene became possible. The share of the latter reactions in the overall transformations can be approximated through T/α−MSt+C ratio in the reaction products (Fig. 5).

For the γ-Al2O3–Cr catalytic system and using heptane as solvent for styrene dimers, it is close to unity and only slightly higher than for alumina. It indicates that the main hydrogen sources are coking reactions. When methylcyclohexane was used as the solvent, the ratio became higher reaching the values within 1.3–1.4 range. Such results indicate that this particular solvent turned out to be an additional source of hydrogen.

The SiO2–Al2O3(13 %)–Cr catalytic system

The catalytic system based on silica–alumina is entirely different from the system in which alumina was used as the chromium ions carrier. Pure silica–alumina is a strong Brønsted acid. It catalyzes cumene dealkylation with a selectivity of about 94 % and is able to protonate styrene dimer both in the aliphatic chain as well as in aromatic ring positions. In the first case, styrene isomeric dimers were formed together with toluene, α-methylstyrene, ethylbenzene and styrene while in the second case, derivatives of indane, indene and naphthalene appeared among reaction products [2]. The introduction of chromium ions onto silica–alumina surface resulted in a decrease in the concentration of acid centers and the appearance of redox sites. It is worth noting that even at the highest chromia loading (5 %) the nature of the SiO2–Al2O3(13 %)–Cr system did not change. It remained a strong Brønsted acid whose active centers possess the same acid strength as pure silica–alumina. This is illustrated in Fig. 6 where styrene dimer conversion is plotted as a function of catalyst acidity. The conversion of cumene to benzene was assumed as an approximate measure of catalyst acid properties. It can be observed that the decrease of acidity caused by a rise in the concentration of chromium ions results in a proportional reduction in the conversion of styrene dimers to products of reactions catalyzed by acid sites such as benzene and dicyclic compounds like indane, indene, naphthalene derivatives. These are the products of internal alkylation reaction followed by dealkylation. Other correlations can be observed for ethylbenzene formation where, there is no relevant conversion versus acidity relation and for styrene dimers isomerization, where the decrease in the concentration of acid sites was accompanied by a rise in conversion to different styrene dimers. In these cases, the reaction proceeds through alkyl chain protonation step. It seems likely that chromium ions eliminated the strongest acid centers, which are able to attach a proton to an aromatic ring but did not have any effect on the other sites, which can only efficiently protonate the double bond in the alkyl chain of the styrene dimer. The diphenylbutyl cation formed undergoes two reactions i.e., isomerization and β-cleavage. The results show that the former reaction is so rapid that the overall transformation leads to isomerized dimers as primary products. Internal alkylation and dealkylation reaction rates get lower and the quantity of styrene dimers in the products rise with a decrease in the acidity of the catalytic system. A slightly higher conversion to ethylbenzene was observed when methylcyclohexane was used as solvent for styrene dimers. This indicates that both acid and redox sites of SiO2–Al2O3(13 %)–Cr catalysts can catalyze the reaction involving styrene dimers leading to coke and hydrogen as well as methylcyclohexane transformation resulting in toluene and hydrogen formation. The presumed coke precursor-1,4-diphenylbutadiene, gave higher styrene oligomers as the main liquid products in reactions performed over silica–alumina. Thus one can expect that the mechanism of coking is similar for both the SiO2–Al2O3(13 %)–Cr and γ-Al2O3–Cr catalysts.

The influence of acidic properties of the SiO2–Al2O3(13 %)–Cr system on styrene dimer conversion to: (black upper triangle) styrene dimer isomers (heptane); (white square) benzene (heptane); (black circle) dicyclic compounds (heptane); (white upper triangle) ethylbenzene (heptane); (black left faced triangle) ethylbenzene (methylcyclohexane) for different solvents

The reactions of styrene dimers which take place in the presence of Brønsted and Lewis acid centers as well as redox sites are summarized in the Scheme 3.

Conclusions

Styrene dimer transformations at 753 K over catalysts possessing: acid Lewis centers as well as weak Brønsted sites of HO > −2.2 (γ-Al2O3); acid Lewis, weak Brønsted sites of −3.5 < HO ≤ −2.2 and redox centers (γ-Al2O3–Cr); strong Brønsted sites of −14 < HO ≤ −3.5 (SiO2–Al2O3(13 %)), strong Brønsted sites of 14 < HO ≤ −3.5 and redox centers (SiO2–Al2O3(13 %)–Cr) have been studied.

It was established that the following surface groups are responsible for catalytic activity in styrene dimers transformation. γ-Al2O3: OH group adjacent to Al3+ cation (alkenyl chain protonation) and Al3+ (allylic anion generation); γ-Al2O3–Cr: Brønsted acid centers originating from chromium ions at high oxidation states (alkenyl chain protonation) and Cr3+ redox sites (allylic cation generation); SiO2–Al2O3(13 %)–Cr: Brønsted acid centers of silica–alumina (alkenyl chain and aromatic ring protonation) and Cr3+ redox sites (allylic cation generation). The protonation of styrene dimer at the alkenyl chain leads to β-cleavage to toluene and α-methylstyrene as well as to styrene and ethylbenzene. The allylic species that are formed react to different styrene dimer isomers and through a diphenylbutadiene intermediate to coke. The use of methylcyclohexane as solvent for the styrene dimers in the presence of chromium containing catalysts results in aromatization reaction leading to toluene and hydrogen. The presence of the later reactant in the system causes styrene and α-methylstyrene hydrogenation to ethylbenzene and cumene.

References

Kaminsky W, Hartman F (2000) Angew Chem Int Ed 39:331–333

Marczewski M, Kamińska E, Marczewska H, Godek M, Rokicki G, Sokołowski J (2013) Appl Catal B 129:236–246

Marczewski M, Kamińska E, Marczewska H (2013) React Kinet Mech Cat 108:59–68

Ferreira ML, Rueda EH (2002) J Mol Catal A 178:147–160

Gates BC, Katzer JR, Schuit GCA (1979) Chemistry of catalytic processes. Mc-Graw-Hill, New York, pp 15–16

Bourne BH, Cannings FR, Pitkethly C (1971) J Phys Chem 76:220–226

Laatikainen M, Vahteristo K, Saukkonen S, Linstrőm M (1996) Ind Eng Res 35:2103–2109

Busca G, Finocchio E, Lorezell V, Trombetta M, Rossini SA (1996) J Chem Soc, Faraday Trans 92:4687–4693

Gabrienko AA, Arzumanov SS, Toktariev AT, Stepanov AG (2012) J Phys Chem C 116:21430–21438

Marcilly C (2006) Acido-basic catalysis. Editions technip, Paris, pp 93–103

Corma A, Wojciechowski BW (1980) Catal Rev Sci Eng 24:1–65

Sohn JR, Ryu SG (2001) Catal Lett 74:105–110

Mishra T, Parida K (1998) Appl Catal A 174:91–98

Lin R, White RL (1997) J Appl Polym Sci 63:1287–1289

Lin R, White RL (1996) ACS Preprints Div Fuel Chem 41:1165–1169

Woo OS, Ayala, Broadbelt LJ (2000) Catal Today 55:161–171

Ukei H, Hirose T, Horikawa S, Takai Y, Taka M, Azuma N, Ueno A (2000) Catal Today 62:67–75

Carre S, Tapin B, Gnep NS, Revel R, Magnoux P (2013) Appl Catal A 372:26–33

Trombetta M, Busca G, Rossini SA, Piccoli V, Cornaro U (1997) J Catal 168:334–348

Sohn JR, Ryu SG (2001) Catal Lett 74:105–110

Guisnet M, Magnoux P (2001) Appl Catal A 212:83–96

Acknowledgments

This work was sponsored by Polish Ministry of Education (Project No. N N209 084338) 2010–2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Marczewski, M., Kamińska, E., Marczewska, H. et al. Decomposition of styrene dimers on Al2O3–Cr and Al2O3–SiO2–Cr catalysts of acid and redox nature. Reac Kinet Mech Cat 111, 549–567 (2014). https://doi.org/10.1007/s11144-013-0652-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-013-0652-4