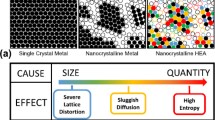

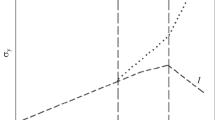

The state of the grain boundaries and the solid solution is analyzed for influence on the yield stress over a wide range of grain sizes for pure metals, low-doped alloys, and multicomponent solid solutions, including high-entropy alloys. A generalized equation is derived using the averaging integrals to describe the yield stress and hardness normalized to Young’s modulus versus the grain size. The potential to reach the maximum hardening for nanostructured materials through the use of grain-boundary engineering is considered. The concept of ‘useful’ impurities intended to bring the strength of such materials to the level comparable with the maximum (theoretically) possible one (E/2π–E/30) is proposed.

Similar content being viewed by others

References

A. H. Chokshi and A. Rosen, “On the validity of the Hall–Petch relationship in nanocrystalline materials,” Scr. Metall. Mater., 23, 1679–1683 (1989).

V. A. Pozdnyakov and M. A. Glezer, “On anomalies of the Hall–Petch relation for nanomaterials,” Pis’ma Zh. Exp. Teor. Fiz., 21, No. 1, 31–36 (1995).

H. Conrad and J. Narayan, “On the grain size softening in nanocrystalline materials,” Scr. Mater., 42, No. 11, 1025–1030 (2000).

R. A. Andrievskii and A. M. Glezer, “Size effects in nanocrystalline materials. II. Mechanical and physical properties,” Fiz. Met. Metalloved., 89, No. 1, 91–112 (2000).

C. Carlton and P. J. Ferreira, “What is behind the inverse Hall–Petch behavior in nanocrystalline materials,” Acta Mater., 55, 3749–3756 (2007).

G. A. Malygin, “Ductility and strength of micro- and nanocrystalline materials (overview),” Fiz. Tverd. Tela, 49, No. 6, 961–982 (2007).

U. F. Kocks, “The relation between polycrystal deformation and single crystal deformation,” Metall. Trans., 1, No. 5, 1121–1143 (1970).

G. Langford and M. Cohen, “Strain hardening of iron by severe plastic deformation,” Trans. Am. Soc. Mech. Eng., 62, 623–638 (1969).

A. W. Thompson, “Substructure strengthening mechanisms,” Metall. Trans., 8A, No. 6, 833–842 (1977).

S. A. Firstov, T. G. Rogul, and O. A. Shut, “Strengthening of polycrystals in transition from micro- to nanostructured state,” Fiz. Khim. Mekh. Mater., No. 6, 5–12 (2009).

S. A. Firstov, T. G. Rogul, and O. A. Shut, “Generalized dependence of yield stress on grain size,” Deform. Razrush. Mater., No. 1, 2–10 (2015).

S. A. Firstov, T. G. Rogul, and S. N. Dub, “Grain boundary engineering of nanostructured chromium films,” in: Innovative Superhard Materials and Sustainable Coatings for Advanced Manufacturing (May 12–15, 2004, Kyiv, Ukraine), Springer (2005), pp. 225–232.

S. O. Firstov, T. G. Rogul, V. L. Svechnikov, et al., “Concept of useful impurities and mechanical properties of chromium and molybdenum films,” Fiz. Khim. Mekh. Mater., 42, No. 1, 113–119 (2006).

O. E. Hall, “Deformation and ageing of mild steel,” Proc. Phys. Soc. London, Sect. B, 64, No. 1, 747–753 (1951).

N. J. Petch, “The cleavage strength of polycrystals,” J. Iron Steel Inst., 174, 25–28 (1953).

H. Conrad, “Work-hardening model for the effect of grain size on the flow stress of metals,” in: J. J. Burke and V. Weiss (eds.), Ultrafine-Grain Metals, Syracuse University Press (1970).

G. Palumbo, U. Erb, and K. T. Aust, “Triple line disclination effects on the mechanical behavior of materials,” Scr. Metall. Mater., 24, 2347–2350 (1990).

M. Yu. Gutkin and I. A. Ovid’ko, Physical Mechanics of Work-Hardened Structure. Vol. 1. Nanocrystalline Materials [in Russian], Inst. Probl. Mashinostr. RAN, Saint Petersburg (2003), p. 194.

V. G. Gryaznov, M. Yu. Gutkin, A. E. Romanow, et al., “On the yield stress of nanocrystals,” J. Mater. Sci., 28, No. 16, 4359–4365 (1993).

H. S. Kim, Y. Estrin, and M. B. Bush, “Plastic deformation behavior of fine-grained materials,” Acta Mater., 48, No. 2, 493–504 (2000).

S. Takeuchi, “The mechanism of the inverse Hall–Petch relation of nanocrystals,” Scr. Mater., 44, 1483–1487 (2001).

S. G. Zaichenko and A. M. Glezer, “Disclination mechanism of plastic deformation of nanocrystalline materials,” Fiz. Tverd. Tela, 39, No. 11, 2023–2028 (1997).

V. A. Pozdyankov, “Plastic deformation mechanisms and anomalies of the Hall–Petch relation for nanocrystalline materials,” Fiz. Met. Metalloved., 96, No. 1, 114–128 (2003).

M. P. Phaniraj, M. J. Prasad, and A. H. Chokshi, “Grain-size distribution effects in plastic flow and failure,” Mater. Sci. Eng. A, 463, 231–237 (2007).

G. A. Malygin, “Effect of grain-size distribution on the strength and ductility of nanocrystalline materials,” Fiz. Tverd. Tela, 50, No. 6, 1013–1017 (2008).

X. Z. Liao, S. G. Srinivasan, Y. H. Zhao, et al., “Formation mechanism of wide stacking faults in nanocrystalline Al,” Appl. Phys. Lett., 84, No. 17, 1–3 (2004).

H. Hahn and K. A. Radmanabhan, “A model for the deformation of nanocrystalline materials,” Philos. Mag. B, 76, 553–571 (1997).

S. V. Bobylev and I. A. Ovid’ko, “Accommodation of grain-boundary sliding and increase in fracture toughness in deformed nanocrystalline materials,” Mater. Phys. Mech., 29, 43–70 (2016).

T. Shimokawa, A. Nakatani, and H. Kitagawa, “Grain-size dependence of the relationship between intergranular and intragranular deformation of nanocrystalline Al by molecular dynamics simulations,” Phys. Rev. B, 71, 224110–224118 (2005).

S. A. Firstov, T. G. Rogul, V. L. Svechnikov, et al., “Structure, mechanical properties, and nanohardness of polycrystalline chromium and molybdenum coatings produced by magnetron sputtering,” Metallofiz. Noveish. Tekhnol., 25, No. 9, 1153–1164 (2003).

S. A. Firstov, T. G. Rogul, V. T. Marushko, et al., “Structure and microhardness of polycrystalline chromium produced by magnetron sputtering,” Vopr. Materialoved., No. 1 (33), 201–205 (2003).

S. A. Firstov and Yu. F. Lugovskoi, “Effect of the microstructure on the strength of composite materials under cyclic and static loads,” Élektron. Microsc. Prochn. Mater., No. 15, 83–88 (2008).

V. I. Trefilov, V. F. Moiseev, E. P. Pechkovskii, et al., Strain Hardening and Destruction of Polycrystalline Metals [in Russian], Naukova Dumka, Kyiv (1987), p. 245.

A. V. Nokhrin, V. N. Chuvildeev, V. I. Kopylov, et al., Mechanical Properties of Nano- and Microcrystalline Metals [in Russian], Nizhniy Novgorod (2007), p. 46.

S. A. Firstov and T. G. Rogul, “Theoretical strength and theoretical hardness,” Deform. Razrush. Mater., No. 5, 1–7 (2011).

N. Wang, Z. Wang, K. T. Aust, et al., “Effect of grain size of the mechanical properties of nanocrystalline materials,” Acta Metall. Mater., 43, 519–524 (1995).

D. M. Marsh, “Plastic flaw in glass,” Proc. R. Soc., No. A279, 420–424 (1964).

S. A. Firstov, V. Yu. Kulikovskii, T. G. Rogul, et al., “Mechanical properties of nanocrystalline chromium films with small oxygen additions,” Nanocryst. Materialoved., No. 4, 31–41 (2011).

A. A. Fedorov, M. Yu. Gutkin, and I. A. Ovid’ko, “Triple junction diffusion and plastic flow in finegrained materials,” Scr. Mater., 47, No. 1, 51–55 (2002).

E. É. Glikman and R. E. Bruver, “Equilibrium grain-boundary segregation and intercrystallite cold brittleness of solid solutions,” Metallofiz., No. 43, 42–63 (1972).

T. S. Ke, “A grain boundary model and mechanism of viscous intercrystalline slip,” J. Appl. Phys., 20, 274–282 (1949).

A. I. Il’insky, A. E. Barmin, and S. I. Lyabuk, “Structure and strength characteristics of dispersion-hardened composite foils (films) based on iron and nickel,” Funct. Mater., 20, No. 4, 477–484 (2013).

M. Danylenko, V. Gorban, Yu. Podrezov, et al., “Gradient structure formation by severe plastic deformation,” Mater. Sci. Forum, 503–504, 787–792 (2006).

D. R. Lesuer, C. K. Syn, and O. D. Sherby, “Influence of severe plastic deformation on the structure and properties of ultrahigh-carbon steel wire,” in: T. C. Lowe and R. Z. Valiev (eds.), Investigations and Applications of Severe Plastic Deformation, NATO Science Series. 3. High Technology, Kluwer Academic Publishers (2000), Vol. 80, pp. 357–366.

G. T. Hahn, A. Gilbert, and R. I. Jaffee, “The effects of solutes on the brittle–ductile transition in refractory metals,” in: Refractory Metals and Alloys, Interscience Publishers, New York (1963).

S. Firstov, V. Kulikovsky, T. Rogul, et al., “Effect of small concentrations of oxygen and nitrogen on the structure and mechanical properties of sputtered titanium films,” Surf. Coat. Technol., 206, 3580–3585 (2012).

A. V. Sergeeva, V. V. Stolyarov, R. Z. Valiev, et al., “Advanced mechanical properties of pure titanium with ultrafine grained structure,” Scr. Mater., 45, 747–752 (2001).

A. R. Kutsar, M. N. Pavlovskii, and V. V. Komisarov, “Observation of two-wave configuration of blast wave in titanium,” Pis’ma Zh. Exp. Teor. Fiz., 35, No. 3, 91–94 (1982).

K. H. Huang, A Study on the Multicomponent Alloy System Containing Equimolar Elements: Master's Thesis, National Tsing Hua University, Taiwan (1995).

J. W. Yeh, Y. L. Chen, S. J. Lin, et al., “High-entropy alloys––a new era of exploitation,” Mater. Sci. Forum, 560, 1–9 (2007).

Y. Zhang, “Mechanical properties and structures of high entropy alloys and bulk metallic glasses composites,” Mater. Sci. Forum, 654–656, 1058–1061 (2010).

O. N. Senkov, G. B. Wilks, D. B. Miracl, et al., “Refractory high-entropy alloys,” Intermetallics, 18, 1758–1765 (2010).

O. N. Senkov, J. M. Scott, S. V. Sencova, et al., “Microstructure and room properties of a high-entropy TaNbHfZrTi alloy,” J. Alloys Compd., 509, 6043–6048 (2011).

S. A. Firstov, V. F. Gorban, N. A. Krapivska, et al., “Strengthening and mechanical properties of as-cast high-entropy alloys,” Compos. Nanostruct., No. 2, 5–20 (2011).

S. A. Firstov, T. G. Rogul, N. A. Krapivka, et al., “Solid-solution strengthening of high-entropy AlTiVCrNbMo alloy,” Deform. Razrush. Mater., No. 2, 9–16 (2013).

S. A. Firstov, T. G. Rogul, N. A. Krapivka, et al., “Structural features and solid-solution strengthening of high-entropy CrMnFeCoNi alloy,” Powder Metall. Met. Ceram., 55, No. 3–4, 225–235 (2016).

R. L. Fleischer, “Substitutional solution hardening,” Acta Metall., 11, 203–209 (1963).

P. K. Huang, J. W. Yeh, T. T. Shum, et al., “Multiprincipal-element alloys improved oxidation and wear resistance for thermal spray coating,” Adv. Eng. Mater., 6, 74–78 (2004).

W. H. Liu, Y. Wu, J. Y. He, et al., “Grain growth and the Hall–Petch relationship in a high-entropy FeCrNiCoMn alloy,” Scr. Mater., 68, 526–529 (2013).

D. Wu, J. Zhang, J. C. Huang, et al., “Grain-boundary strengthening in nanocrystalline chromium and the Hall–Petch coefficient of body-centered cubic metals,” Scr. Mater., 68, 118–121 (2013).

Z. Wu, Temperature and Alloying Effects on the Mechanical Properties of Equiatomic FCC Solid Solution Alloys: PhD Dissertation, University of Tennessee, USA (2014), p. 125: http://trace.tennessee.edu/utk_graddiss/2884.

Electronic resource: www.webelements.com .

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 57, Nos. 3–4 (520), pp. 43–61, 2018.

Rights and permissions

About this article

Cite this article

Firstov, S.A., Rogul, T.G. & Shut, O.A. Hardening in the Transition to Nanocrystalline State in Pure Metals and Solid Solutions (Ultimate Hardening). Powder Metall Met Ceram 57, 161–174 (2018). https://doi.org/10.1007/s11106-018-9964-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-018-9964-2