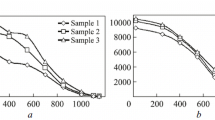

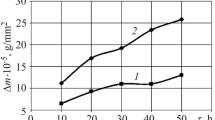

The wear-resistance of powder cobalt alloys with titanium carbide is studied in fretting corrosion conditions at 20, 300, 650, 800, and 1050°C under varying loads and durations. The alloys of different porosity are obtained by hot pressing of the powders of cobalt, chromium, aluminum, iron, and titanium carbide. The wear of alloys with 30, 50, and 70 vol.% carbide is determined. The dependence of the average linear wear of powder alloys on the sample porosity and loads during the tests is established. The wear-resistance of alloys is mainly affected by the temperature: the average linear wear rate increases with increasing temperature, regardless of the carbide content. The results are the basis for choosing the optimal alloy composition for the field tests during developing friction materials for aviation applications.

Similar content being viewed by others

References

G. N. Tretyachenko, S. V. Kravchuk, R. I. Kuriat, and A. P. Voloshenko, Bearing Capacity of Gas Turbine Blades under Transient Heat and Power Effects [in Russian], Nauk. Dumka, Kiev (1975), p. 295.

G. P. Dmitrieva, T. S. Cherepova, T. A. Kosorukova, and V. I. Nichiporenko, “Structure and properties of the cobalt-based wear-resistant alloy with niobium carbide,” Metallofiz. Nov. Tekhnol., 37, No. 7, 973–986 (2015).

T. S. Cherepova, G. P. Dmitrieva, A. V. Nosenko, and O. M. Semirga, “Wear-resistant alloy to protect the contact surfaces of the working blades of aircraft engines from oxidation at high temperatures,” Nauka Innovats., 10, No. 4, 22–31 (2014).

V. A. Leontiev, S. D. Zalichikhis, E. V. Kondrtayuk, and V. E. Zamkovoi, “Restoration of GTE using new technologies and materials,” Vest. Dvigatelestr., No. 4, 99–103 (2006).

G. I. Peichev, V. E. Zamkovoi, and N. V. Andreichenko, “Developing the analogue of KhTN-61 wear-resistant alloy with high heat-resistance for gas turbine engines,” Aviats. Kosm. Tekh. Tekhnol., No. 8, 11–13 (2007).

A. K. Shurin, G. P. Dmitrieva, N. I. Matyushenko, et al., “High-temperature salt corrosion of cobalt carbide eutectic alloys,” Zashch. Metall., 26, No. 4, 659–661 (1990).

R. F. Voitovich, Oxidation of Carbides and Nitrides [in Russian], Nauk. Dumka, Kiev (1981), p. 192.

O. I. Dukhota and O. V. Tisov, “Study of wear- and heat-resistant composite alloys under high-temperature fretting conditions,” Probl. Ter. Znosh.: Nauk. Tekh. Zbir. Nats. Aviats. Univ., No. 53, 195–200 (2010).

T. S. Cherepova, G. P. Dmitrieva, and N. V. Andriichenko. Cobalt-Based Alloy. Ukrainian Patent No. 92883, Ukraine. Appl. 18.06.2010; Publ. 10.12.2010; Bull. No. 17.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 55, Nos. 5–6 (509), pp. 152–158, 2016.

Rights and permissions

About this article

Cite this article

Cherepova, T.S., Dmitrieva, G.P. The Wear Features of Powder Cobalt Alloys Strengthened with Titanium Carbide. Powder Metall Met Ceram 55, 374–378 (2016). https://doi.org/10.1007/s11106-016-9816-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-016-9816-x