Abstract

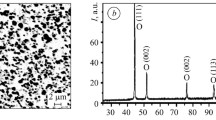

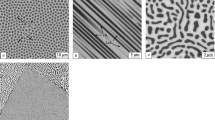

We have studied the structure and mechanical properties of eutectic alloys β-NiAl + γ-Re of the ternary system Ni-Al-Re. We have established that the best combination of mechanical characteristics, determined by local loading with a rigid indentor, is exhibited by the alloy containing 2.5 at.% Re, the structure of which consists of the eutectic β-NiAl + γ-Re. Rhenium inclusions can inhibit movement of cracks in the material, and also can play the role of traps for cracks. Brittle intercrystallite fracture is characteristic of the alloy consisting of one-phase intermetallic NiAl. Mixed fracture is typical of the eutectic alloy β-NiAl + γ-Re, with transcrystallite cleavage predominating. We have shown that plastic interlayers of a rhenium phase within the microstructure increase the crack resistance of a detonation coating made from eutectic alloys β-NiAl + γ-Re.

Similar content being viewed by others

References

R. Darolia, D. F. Lahrman, and R. D. Field, “Overview of NiAl for high temperature structural application,” in: Ordered Intermetallics: Physical Metallurgy and Mechanical Behaviour, Kluwer Academic Publishers, Dordrecht; Boston; London (1992), pp. 679–698.

W. Smarsly and L. Singheiser, “Potential of intermetallics to replace superalloys for advanced operation conditions in gas turbines,” J. Mat. Adv. Power Eng., Part II, 1731–1756 (1994).

M. B. Henderson, J. Hannis, and G. McColvin, “Materials issues for the industrial gas turbines, ” in: Advanced Materials and Processes for Gas Turbines, The Minerals, Metals & Materials Society, Warrendale, Pennsylvania (2003), pp. 3–13.

A. Misra, Z. L. Wu, and M. T. Kush, “Microstructures and mechanical properties of directionally solidified NiAl-Mo and NiAl-Mo(Re) eutectic alloys,” Mat. Sci. Eng., A239-240, 75–87 (1997).

D. Golberg and G. Sauthoff, “Effects of ageing at 673 K on the compressive behaviour of <110> oriented (“soft”d) NiAl single crystals and polycrystals with and without Ti additions, ” Intermetallics, 4, 143–158 (1996).

J. D. Whittenberg, R. D. Noebe, D. R. Johnson, and B. F. Oliver, “Compressive and tensile creep of a directionally solidified NiAl − 14.5 at.% Ta alloy,” Intermetallics, 5, 173–183 (1997).

D. L. Davidson and F. R. Brotzen, “Plastic deformation of molybdenum-rhenium alloy crystals,” Acta Metal., 18, No. 5, 463–470 (1970).

G. T. Hahn, A. Gilbert, R. I. Jaffee, et al., Refractory Metals and Alloys, Interscience, Wiley (1963), pp. 23–24.

L. A. Cornish and M. J. Witcomb, “A metallographic study of the Ni-Al-Re phase diagram,” Alloy Comp., 291, 145–166 (1999).

R. Rablbauer, G. Frommeyer, and F. Stein, “Determination of the quasi-binary eutectic NiAl-Re system by DTA and microstructural investigations,” Mat. Sci. Eng., A343, 301–307 (2003).

O. M. Barabash, M. Yu. Barabash, and V. E. Oliker, “Effect of rhenium on formation of the structure for eutectic alloys based on β-NiAl + γ-Re,” Poroshk. Metall., Nos. 3–4, 84–89 (2003).

Yu. V. Mil’man, “New techniques for micromechanical testing of materials by the method of local loading with a hard indentor,” in: Modern Materials Science of the Twenty-First Century [in Ukrainian], Nauk. Dumka, Kiev (1998), pp. 637–657.

D. M. Verbilo, Physical Characteristics of Deformation and Fracture of High-Porosity Materials, PhD Thesis [in Russian], Kiev (2003).

A. I. Zverev, S. Yu. Sharivker, and E. A. Astakhov, Detonation Spraying of Coatings [in Russian], Sudostroenie, Leningrad (1979).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Nos. 3–4(448), pp. 78–87, March–April, 2006.

Rights and permissions

About this article

Cite this article

Oliker, V.E., Barabash, M.Y., Grechishkin, E.F. et al. Mechanical properties of eutectic alloys β-NiAl + γ-Re and spray coatings. Powder Metall Met Ceram 45, 173–180 (2006). https://doi.org/10.1007/s11106-006-0060-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-006-0060-7