Abstract

Purpose

It was investigated if continuous wet granulation and drying could be combined in a twin-screw granulator with the aim to provide (pre-)dried granules in a single-step process, i.e. in-barrel-drying.

Methods

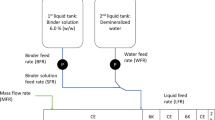

To have a consistent and robust material propulsion mechanism, a twin-screw granulator was divided into two compartments. One compartment was operated at lower temperature to granulate and to pre-heat the material, while another compartment was operated at very high temperature to evaporate the granulation liquid as rapidly as possible. Design of experiments was used to investigate the in-barrel-drying process in detail. The process was further investigated for twin-screw wet granulation with API suspension feed, and compared against traditional fluidised-bed drying. Granule and compact properties were evaluated to study the process impact on the product quality.

Results

In-barrel-drying was demonstrated as feasible and yielded completely dried and granulated material at specific settings. The evaporation zone temperature and the processed mass of water were identified as key parameters to balance the evaporation capacity of the process and the material throughput. Granules and compacts showed an acceptable product quality.

Conclusions

In-barrel-drying can be used to condense the wet granulation and drying process steps into one piece of equipment, thereby limiting or even omitting downstream drying process steps.

Similar content being viewed by others

Abbreviations

- API:

-

Active pharmaceutical ingredient

- CP:

-

Centre point

- DOE:

-

Design of experiments

- HPLC:

-

High performance liquid chromatography

- L/S ratio:

-

Liquid-to-solid mass flow ratio

- LOD:

-

Loss-on-drying

- ScSp:

-

Screw speed

- Temp.Eva:

-

Temperature in the evaporation zone

- Temp.Pre:

-

Temperature in the pre-heating zone

- TMMF:

-

Total material mass flow rate

- TSG:

-

Twin-screw granulator

References

Crean B, Chen X, Banks SR, Cook WG, Melia CD, Roberts CJ. An investigation into the rheology of pharmaceutical inter-granular material bridges at high shear rates. Pharm Res. 2009;26(5):1101–11.

Meier R, Thommes M, Rasenack N, Krumme M, Moll K-P, Kleinebudde P. Simplified formulations with high drug loads for continuous twin-screw granulation. Int J Pharm. 2015;496(1):12–23.

van den Ban S, Goodwin DJ. The impact of granule density on tabletting and pharmaceutical product performance. Pharm Res. 2017:1–10.

Schmidt A, de Waard H, Moll K-P, Krumme M, Kleinebudde P. Quantitative assessment of mass flow boundaries in continuous twin-screw granulation. Chimia. 2016;70(9):604–9.

Rana AS, Hari Kumar S. Manufacturing defects of tablets-a review. JDDT. 2013;3(6):200–6.

Amidon GE, Houghton ME. The effect of moisture on the mechanical and powder flow properties of microcrystalline cellulose. Pharm Res. 1995;12(6):923–9.

Fonteyne M, Vercruysse J, Díaz DC, Gildemyn D, Vervaet C, Remon JP, et al. Real-time assessment of critical quality attributes of a continuous granulation process. Pharm Dev Technol. 2013;18(1):85–97.

Vercruysse J, Córdoba Díaz D, Peeters E, Fonteyne M, Delaet U, Van Assche I, et al. Continuous twin screw granulation: influence of process variables on granule and tablet quality. Eur J Pharm Biopharm. 2012;82(1):205–11.

Thompson M, Sun J. Wet granulation in a twin-screw extruder: implications of screw design. J Pharm Sci. 2010;99(4):2090–103.

Sayin R, El Hagrasy AS, Litster JD. Distributive mixing elements: towards improved granule attributes from a twin screw granulation process. Chem Eng Sci. 2015;125:165–75.

Waje SS, Thorat BN, Mujumdar AS. Screw conveyor dryer: process and equipment design. Dry Technol. 2007;25(1):241–7.

Osman HB. Granular flow and heat transfer in a screw conveyor heater: a discrete element modeling study. Master thesis. University of Singapore. 2012.

Meena AK, Desai D, Development SAT. Optimization of a wet granulation process at elevated temperature for a poorly compactible drug using twin screw extruder for continuous manufacturing. J Pharm Sci. 2017;106(2):589–600.

Seem TC, Rowson NA, Ingram A, Huang Z, Yu S, de Matas M, et al. Twin screw granulation — a literature review. Powder Technol. 2015;276:89–102.

Meier R, Moll K-P, Krumme M, Kleinebudde P. Impact of fill-level in twin-screw granulation on critical quality attributes of granules and tablets. Eur J Pharm Biopharm. 2017;115:102–12.

Eriksson L, Johansson E, Kettaneh-Wold N, Wikström C, Wold S. Design of experiments: principles and applications. 3rd revised and enlarged edition. Sweden: Umetrics Academy; 2008.

Guo Z, Li D, Wang B. A novel concept for convective heat transfer enhancement. Int J Heat Mass Transf. 1998;41(14):2221–5.

Kumar A, Vercruysse J, Toiviainen M, Panouillot P-E, Juuti M, Vanhoorne V, et al. Mixing and transport during pharmaceutical twin-screw wet granulation: experimental analysis via chemical imaging. Eur J Pharm Biopharm. 2014;87(2):279–89.

Montgomery R. Viscosity and thermal conductivity of air and diffusivity of water vapor in air. J Meteorol. 1947;4(6):193–6.

Graves R, Kollie T, McElroy D, Gilchrist K. The thermal conductivity of AISI 304L stainless steel. Int J Thermophys. 1991;12(2):409–15.

Iveson SM, Litster JD, Hapgood K, Ennis BJ. Nucleation, growth and breakage phenomena in agitated wet granulation processes: a review. Powder Technol. 2001;117(1–2):3–39.

El Hagrasy A, Hennenkamp J, Burke M, Cartwright J, Litster J. Twin screw wet granulation: influence of formulation parameters on granule properties and growth behavior. Powder Technol. 2013;238:108–15.

Airaksinen S, Karjalainen M, Räsänen E, Rantanen J, Yliruusi J. Comparison of the effects of two drying methods on polymorphism of theophylline. Int J Pharm. 2004;276(1–2):129–41.

Meier R, Thommes M, Rasenack N, Moll KP, Krumme M, Kleinebudde P. Granule size distributions after twin-screw granulation – do not forget the feeding systems. Eur J Pharm Biopharm. 2016;106:59–69.

Lee KT, Ingram A, Rowson NA. Twin screw wet granulation: the study of a continuous twin screw granulator using positron emission particle tracking (PEPT) technique. Eur J Pharm Biopharm. 2012;81(3):666–73.

Faure A, York P, Rowe RC. Process control and scale-up of pharmaceutical wet granulation processes: a review. Eur J Pharm Biopharm. 2001;52(3):269–77.

Lustig-Gustafsson C, Johal HK, Podczeck F, Newton J. The influence of water content and drug solubility on the formulation of pellets by extrusion and spheronisation. Eur J Pharm Sci. 1999;8(2):147–52.

Yu S, Reynolds GK, Huang Z, de Matas M, Salman AD. Granulation of increasingly hydrophobic formulations using a twin screw granulator. Int J Pharm. 2014;475(1):82–96.

Jelen P, Coulter ST. Effects of supersaturation and temperature on the growth of lactose crystals. J Dairy Sci. 1973;38:1182–5.

Sun C, Grant DJW. Effects of initial particle size on the tableting properties of l-lysine monohydrochloride dihydrate powder. Int J Pharm. 2001;215(1–2):221–8.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schmidt, A., de Waard, H., Kleinebudde, P. et al. Continuous Single-Step Wet Granulation with Integrated in-Barrel-Drying. Pharm Res 35, 167 (2018). https://doi.org/10.1007/s11095-018-2451-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11095-018-2451-0