Abstract

Purpose

The purpose of this study was to identify and optimize spray drying parameters of importance for the design of an inhalable powder formulation of a cationic liposomal adjuvant composed of dimethyldioctadecylammonium (DDA) bromide and trehalose-6,6′-dibehenate (TDB).

Methods

A quality by design (QbD) approach was applied to identify and link critical process parameters (CPPs) of the spray drying process to critical quality attributes (CQAs) using risk assessment and design of experiments (DoE), followed by identification of an optimal operating space (OOS). A central composite face-centered design was carried out followed by multiple linear regression analysis.

Results

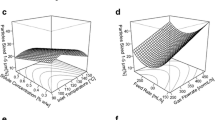

Four CQAs were identified; the mass median aerodynamic diameter (MMAD), the liposome stability (size) during processing, the moisture content and the yield. Five CPPs (drying airflow, feed flow rate, feedstock concentration, atomizing airflow and outlet temperature) were identified and tested in a systematic way. The MMAD and the yield were successfully modeled. For the liposome size stability, the ratio between the size after and before spray drying was modeled successfully. The model for the residual moisture content was poor, although, the moisture content was below 3% in the entire design space. Finally, the OOS was drafted from the constructed models for the spray drying of trehalose stabilized DDA/TDB liposomes.

Conclusions

The QbD approach for the spray drying process should include a careful consideration of the quality target product profile. This approach implementing risk assessment and DoE was successfully applied to optimize the spray drying of an inhalable DDA/TDB liposomal adjuvant designed for pulmonary vaccination.

Diagram of an optimal operating space highlighting the process design space where the critical criteria are met: White: No criteria met. Dark blue: One criterion met. Light blue: Two criteria met. Green: All criteria met.

Similar content being viewed by others

Abbreviations

- CPP:

-

critical process parameter

- CQA:

-

critical quality attribute

- DDA:

-

dimethyldioctadecylammonium

- DoE:

-

Design of Experiments

- FPF:

-

fine particle fraction

- MMAD:

-

mass median aerodynamic diameter

- OOS:

-

optimal operating space

- PDI:

-

polydispersity index

- QbD:

-

Quality by Design

- QTPP:

-

quality target product profile

- TDB:

-

trehalose-6,6′-dibehenate

- VMD:

-

volumetric mean diameter

References

Bloom DE, Canning D, Weston M. The value of vaccination. World Econ. 2005;6(3):15–39.

Ingvarsson PT, Yang M, Nielsen HM, Rantanen J, Foged C. Stabilization of liposomes during drying. Expert Opin Drug Deliv. 2011;8(3):375–88.

Tonnis WF, Kersten GF, Frijlink HW, Hinrichs WLJ, de Boer AH, Amorij JP. Pulmonary vaccine delivery: a realistic approach? J Aerosol Med Pulm Drug Deliv. 2012;25(5):249–60.

Mobley WC. The effect of Jet-Milling on lyophilized liposomes. Pharm Res. 1998;15(1):149–52.

Seville PC, Li H, Learoyd TP. Spray-dried powders for pulmonary drug delivery. Crit Rev Ther Drug Carrier Syst. 2007;24(4):307–60.

Sou T, Meeusen EN, de Veer M, Morton DAV, Kaminskas LM, McIntosh MP. New developments in dry powder pulmonary vaccine delivery. Trends Biotechnol. 2011;29(4):191–8.

Chow AHL, Tong HHY, Chattopadhyay P, Shekunov BY. Particle engineering for pulmonary drug delivery. Pharm Res. 2007;24(3):411–37.

Byron PR. Prediction of drug residence times in regions of the human respiratory tract following aerosol inhalation. J Pharm Sci. 1986;75(5):433–8.

Martin TR, Frevert CW. Innate immunity in the lungs. Proc Am Thorac Soc. 2005;2(5):403–11.

Holt PG. Pulmonary dendritic cells in local immunity to inert and pathogenic antigens in the respiratory tract. Proc Am Thorac Soc. 2005;2(2):116–20.

Blank F, Rothen-Rutishauser B, Gehr P. Dendritic cells and macrophages form a transepithelial network against foreign particulate antigens. Am J Respir Cell Mol Biol. 2007;36(6):669–77.

Guideline ICHHT. Pharmaceutical development Q8 (R2). Maryland: ICH. 2009.

Rathore AS, Winkle H. Quality by design for biopharmaceuticals. Nat Biotechnol. 2009;27(1):26.

Yu LX. Pharmaceutical quality by design: product and process development, understanding, and control. Pharm Res. 2008;25(4):781–91.

Davidsen J, Rosenkrands I, Christensen D, Vangala A, Kirby D, Perrie Y, et al. Characterization of cationic liposomes based on dimethyldioctadecylammonium and synthetic cord factor from M. tuberculosis (trehalose 6,6'-dibehenate) - A novel adjuvant inducing both strong CMI and antibody responses. Biochim Biophys Acta Biomembr. 2005;1718(1–2):22–31.

Holten-Andersen L, Doherty TM, Korsholm KS, Andersen P. Combination of the cationic surfactant dimethyl dioctadecyl ammonium bromide and synthetic mycobacterial cord factor as an efficient adjuvant for tuberculosis subunit vaccines. Infect Immun. 2004;72(3):1608–17.

Agger EM, Rosenkrands I, Hansen J, Brahimi K, Vandahl BS, Aagaard C, et al. Cationic liposomes formulated with synthetic mycobacterial cordfactor (CAF01): a versatile adjuvant for vaccines with different immunological requirements. PLoS One. 2008;3(9):e3116.

Christensen D, Foged C, Rosenkrands I, Nielsen HM, Andersen P, Agger EM. Trehalose preserves DDA/TDB liposomes and their adjuvant effect during freeze-drying. Biochim Biophys Acta Biomembr. 2007;1768(9):2120–9.

Ingvarsson PT, Schmidt ST, Christensen D, Larsen NB, Hinrichs WLJ, Andersen P, et al. Designing CAF-adjuvanted dry powder vaccines: spray drying preserves the adjuvant activity of CAF01. J Control Release. 2013;167(3):256–64.

Abdul-Fattah AM, Kalonia DS, Pikal MJ. The challenge of drying method selection for protein pharmaceuticals: product quality implications. J Pharm Sci. 2007;96(8):1886–916.

Maury M, Murphy K, Kumar S, Shi L, Lee G. Effects of process variables on the powder yield of spray-dried trehalose on a laboratory spray-dryer. Eur J Pharm Biopharm. 2005;59(3):565–73.

Crowe LM, Reid DS, Crowe JH. Is trehalose special for preserving dry biomaterials? Biophys J. 1996;71(4):2087–93.

Baldinger A, Clerdent L, Rantanen J, Yang M, Grohganz H. Quality by design approach in the optimization of the spray-drying process. Pharm Dev Technol. 2011;17(4):389–97.

Lunney PD, Cogdill RP, Drennen JK. Innovation in pharmaceutical experimentation Part 1: review of experimental designs used in industrial pharmaceutics research and introduction to Bayesian D-optimal experimental design. J Pharm Innov. 2008;3(3):188–203.

Prinn KB, Costantino HR, Tracy M. Statistical modeling of protein spray drying at the lab scale. AAPS PharmSciTech. 2002;3(1):32–9.

Maltesen MJ, Bjerregaard S, Hovgaard L, Havelund S, van de Weert M. Quality by design - spray drying of insulin intended for inhalation. Eur J Pharm Biopharm. 2008;70(3):828–38.

Mosén K, Bäckström K, Thalberg K, Schaefer T, Kristensen HG, Axelsson A. Particle formation and capture during spray drying of inhalable particles. Pharm Dev Technol. 2004;9(4):409–17.

Vehring R. Pharmaceutical particle engineering via spray drying. Pharm Res. 2008;25(5):999–1022.

Lebrun P, Krier F, Mantanus J, Grohganz H, Yang M, Rozet E, et al. Design space approach in the optimization of the spray-drying process. Eur J Pharm Biopharm. 2011;80(1):226–34.

Sun W, Leopold A, Crowe L, Crowe J. Stability of dry liposomes in sugar glasses. Biophys J. 1996;70(4):1769–76.

Langrish TAG, Fletcher DF. Spray drying of food ingredients and applications of CFD in spray drying. Chem Eng Proc: Proc Int. 2001;40(4):345–54.

Hamborg M, Jorgensen L, Bojsen AR, Christensen D, Foged C. Protein antigen adsorption to the DDA/TDB liposomal adjuvant: effect on protein structure, stability, and liposome physicochemical characteristics. Pharm Res. 2012;30(1):140–55.

Wang W. Instability, stabilization, and formulation of liquid protein pharmaceuticals. Int J Pharm. 1999;185(2):129–88.

Mhatre R, Rathore AS. Quality by design: An overview of the basic concepts. In: Mhatre R, Rathore AS, editors. Quality by design for biopharmaceuticals: Principles and case studies. 1st ed. Hoboken: Wiley; 2009. p. 1–8.

Chan LW, Tan LH, Heng PS. Process analytical technology: application to particle sizing in spray drying. AAPS PharmSciTech. 2008;9(1):259–66.

Hergeth WD, Jaeckle C, Krell M. Industrial process monitoring of polymerization and spray drying processes. Polym React Eng. 2003;11(4):663–714.

Maltesen MJ, van de Weert M, Grohganz H. Design of experiments-based monitoring of critical quality attributes for the spray-drying process of insulin by NIR spectroscopy. AAPS PharmSciTech. 2012;13(3):747–55.

Acknowledgments And Disclosures

Jukka Rantanen and Camilla Foged share senior authorship. The authors would like to acknowledge Dorthe Kyed Ørbæk (University of Copenhagen) for assistance with SEM and the Centre for Nano-Vaccines (CNV) and its members for the collaboration. The authors are grateful to The Danish Council for Strategic Research for funding the project (PTI). The funding source had no involvement in the study or the decision to submit the results for publication.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ingvarsson, P.T., Yang, M., Mulvad, H. et al. Engineering of an Inhalable DDA/TDB Liposomal Adjuvant: A Quality-by-Design Approach Towards Optimization of the Spray Drying Process. Pharm Res 30, 2772–2784 (2013). https://doi.org/10.1007/s11095-013-1096-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-013-1096-2