No Heading

Purpose.

To investigate the background of the observed relationship between measured torque and granule size in high-shear granulation processes.

Methods.

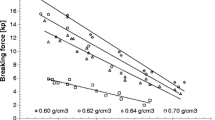

Torque was measured during the granulation process; the behavior of individual wet granules during compaction was investigated using micromanipulation. Surface properties of wet granules were manipulated by coating them with talc.

Results.

The torque-granule size relationship could not be explained by the rise in mass of the individual granules; it occurs rather through an increase in stickiness of the granules when the moisture content is increased. Obviously, the increased stickiness that causes the granules to grow also increases the torque. Increased stickiness was shown to be the result of an increased deformability of the granules at higher moisture contents, in combination with a change in surface properties. The elastic-plastic behavior (ratio of elastic to plastic deformation) was found to change at increasing moisture contents.

Conclusions.

Our results imply that changes in the stickiness of the granular material that may be caused by changes in composition shift the torque-size relationship. This may be of particular importance when, for example, granulation results from placebo batches are used to predict the granule size of drug-containing batches.

Similar content being viewed by others

References

1. P. Holm. High Shear Mixer Granulators. In D. M. Parikh (ed.), Handbook of Pharmaceutical Granulation Technology, Vol. 81. Drugs and the Pharmaceutical Sciences. Marcel Dekker, New York, 1997, pp. 151–204.

2. G. Betz, P. J. Bürgin, and H. Leuenberger. Power consumption profile analysis and tensile strength measurements during moist agglomeration. Int. J. Pharm. 252:11–25 (2003).

3. G. Betz, P. J. Bürgin, and H. Leuenberger. Power consumption measurement and temperature recording during granulation. Int. J. Pharm. 272:137–149 (2004).

4. J. Kristensen, T. Schæfer, and P. Kleinebudde. Direct pelletization in a rotary processor controlled by torque measurements. I. Influence of process variables. Pharm. Dev. Technol. 5:247–256 (2000).

5. H. Leuenberger. Granulation, new techniques. Pharm. Acta Helv. 57:72–82 (1982).

6. P. C. Knight, J. P. K. Seville, A. B. Wellm, and T. Instone. Prediction of impeller torque in high shear powder mixers. Chem. Eng. Sci. 56:4457–4471 (2001).

7. P. Holm, T. Schæfer, and H. G. Kristensen. Granulation in high-speed mixers Part V. Power consumption and temperature changes during granulation. Powder Technol. 43:213–223 (1985).

8. P. Holm, T. Schæfer, and H. G. Kristensen. Granulation in high-speed mixtures Part VI. Effects of process conditions on power consumption and granule growth. Powder Technol. 43:225–233 (1985).

9. M. D. Parker, R. C. Rowe, and N. G. Upjohn. Mixer torque rheometry: A method for quantifying the consistency of wet granulations. Pharm. Tech. Int. 2:50–62 (1990).

10. J. Kristensen, T. Schæfer, and P. Kleinebudde. Direct pelletization in a rotary processor controlled by torque measurements. II. Effects of changes in the content of microcrystralline cellulose. AAPS PharmSci 2:1–8 (2000).

11. G. J. B. Horsthuis, J. A. H. van Laarhoven, R. C. B. M. van Rooij, and H. Vromans. Studies on upscaling parameters of the Gral high shear granulation process. Int. J. Pharm. 92:143–150 (1993).

12. Z. Zhang, R. Saunders, and C. R. Thomas. Mechanical strength of single microcapsules determined by a novel micromanipulation technique. J. Microencapsul. 16:117–124 (1999).

13. R. J. H. Stenekes, S. C. De Smedt, J. Demeester, G. Sun, Z. Zhang, and W. E. Hennink. Pore sizes in hydrated dextran microspheres. Biomacromolecules 1:696–703 (2000).

14. B. Emschermann and F. Müller. Auswertung der Kraftmessung beim Tablettieren. Pharm. Ind. 43:191–194 (1981).

15. C. Gay and L. Leibner. On stickiness. Phys. Today 52:48–52 (1999).

16. D. M. Newitt and J. M. Conway-Jones. A contribution to the theory and practice of granulation. Trans. Instn Chem. Engrs 36:422–442 (1958).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bouwman, A., Henstra, M., Hegge, J. et al. The Relation Between Granule Size, Granule Stickiness, and Torque in the High-Shear Granulation Process. Pharm Res 22, 270–275 (2005). https://doi.org/10.1007/s11095-004-1194-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-004-1194-2