Abstract

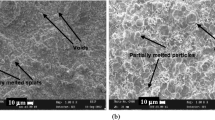

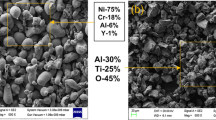

High-temperature oxidation is the major degradation mechanism of boiler and gas turbine components. Superalloys are used in these applications because of their superior mechanical properties and creep resistance, but they lack resistance to oxidation under aggressive environment. In the present investigation, Al2O3–40%TiO2 coating was deposited on Superni718 and Superni600 superalloys by a detonation gun spray process. The as-sprayed coating was characterized by SEM analysis. The high-temperature oxidation behavior of Superni718 and Superni600 and Al2O3–40%TiO2 coating on these superalloys was evaluated in air under cyclic conditions at 800 °C and 900 °C for a total duration of 50 cycles. Each cycle consisted of keeping the samples for one hour at the elevated temperature followed by 20 min cooling in ambient air. Oxidation kinetics were studied using a thermo-gravimetric technique and found to follow the parabolic rate law. The coating was successfully formulated using a detonation gun spray process. The coating was found to be adherent to the substrate superalloys. It was found that among the two alloys, uncoated and coated Superni600 superalloys have much better oxidation resistance as compared to uncoated Superni718 superalloy.

Similar content being viewed by others

References

R. B. Heimann, Plasma Spray Coating Principles and Applications, 2nd ed (VCH Weinheim VCH Publishers Inc, New York, 2008).

R. B. Heimann and H. D. Lehmann, Recent Patents on Mat. Science I, 41 (2008).

M. H. Li, X. F. Sun, J. G. Li, Z. Y. Zhang, T. Jin, H. R. Guan, and Z. Q. Hu, Oxidation of Metals 59, 591 (2003).

N. B. Maledi, J. H. Potgieter, M. Sephton, L. A. Cornish, L. Chown, R. Suss, Hot Corrosion Behaviour of Pt-Alloys for Application in the Next Generation of Gas Turbines, International Platinum Conference - Platinum Surges Ahead. The Southern African Institute of Mining and Metallurgy, 81, (2006).

S. B. Mishra, K. Chandra, and S. Prakash, Surface and Coatings Technology 216, 23 (2013).

S. B. Mishra, S. Prakash, and K. Chandra, Wear 260, 422 (2006).

J. S. Zhang, Z. Q. Hu, Y. Murata, M. Morinaga, and N. Yukawa, Metallurgical and Materials Transactions 24A, 2443 (1993).

S. Esmaeili, C. C. Engler-Pinto Jr., B. Iischner, and F. Rezai-Aria, Scripta Metallurgica et Materialia 32, 1777 (1995).

S. Kamal, R. Jayaganthan, and S. Prakash, Bulletin of Materials Science 33, 299 (2010).

T. S. Sidhu, R. D. Agarwal, and S. Prakash, Surface and Coatings Technology 198, 441 (2005).

B. Pieraggi and F. Dabosi, Materials and Corrosion 38, 584 (1987).

L. Huang, X. F. Sun, H. R. Guan, and Z. Q. Hu, Oxidation of Metals 65, 207 (2006).

M. G. Hocking, Surface and Coatings Technology 62, 460 (1993).

P. S. Sidky and M. G. Hocking, British Corrosion Journal 34, 171 (1991).

O. Knotek: in Handbook of Hard Coatings: Deposition Technologies, properties and Applications, ed. R. F. Bunshah, (Noyes Publishing, Park Ridge, 2001) p. 77

J. Sure, A. R. Shankar, and U. K. Mudali, Optics & Laser Technology 48, 366 (2013).

J. Zhang, J. He, Y. Dong, X. Li, and D. Yan, Journal of Materials Processing Technology 197, 31 (2008).

H. Hazar and U. Ozturk, Renewable Energy 35, 2211 (2010).

M. Kasparova, S. Houdkova, J. Cubrova, Thermally Sprayed Coatings for High Temperature Application, Metal 2012, (Brno, Czech Republic, 2012), p. 1

Y. Zenf, S. W. Lee, and C. X. Ding, Materials Letters 57, 495 (2002).

Y. Wang, S. Jiang, M. Wang, S. Wang, T. D. Xiao, and P. R. Strutt, Wear 237, 176 (2000).

G. R. Li, L. S. Wang, W. W. Zhang, G. J. Yang, X. F. Chen, and W. X. Zhang, Tailoring degradation- resistant thermal barrier coatings based on the orientation of spontaneously formed pores: from retardation to self-improvement. Composites Part B: Engineering 181, 107567 (2020).

M. J. Liu, M. Zhang, X. F. Zhang, G. R. Li, Q. Zhang, C. X. Li, C. J. Li, and G. J. Yang, Transport and deposition behaviors of vapor coating materials in plasma spray physical vapor deposition. Applied Surface Science 486, 80 (2019).

G. H. Meng, B. Y. Zhang, H. Liu, G. J. Yang, T. Xu, X. C. Li, and C. J. Li, Vacuum heat treatment mechanisms promoting the adhesion strength of thermally sprayed metallic coatings. Surface and Coatings Technology 344, 102 (2018).

K. Chokethawai, D. G. McCartney, and P. H. Shipway, Microstructure evolution and thermal stability of an Fe-based amorphous alloy powder and thermally sprayed coatings. Journal of Alloys and Compounds 480, 351 (2009).

H. Zhou, C. Zhang, W. Wang, M. Yasir, and L. Liu, Microstructure and mechanical properties of Fe-based amorphous composite coatings reinforced by stainless steel powders. Journal of Materials Science & Technology 31, 43 (2015).

E. Sadeghi and S. Joshi, Chlorine-induced high-temperature corrosion and erosion corrosion of HVAF and HVOF-sprayed amorphous Fe-based coatings. Surface and Coatings Technology 371, 20 (2019).

H. Guo, S. Zhang, W. H. Sun, and J. Q. Wang, Differences in dry sliding wear behaviour between HVAF-sprayed amorphous steel and crystalline stainless steel coatings. Journal of Materials Science & Technology 35, 865 (2019).

A. Kobayashi, S. Yano, H. Kimura, et al., Fe-based metallic glass coatings produced by smart plasma spraying process. Material Science and Engineering B 148, 110 (2008).

Z. H. Chu, F. S. Wei, X. W. Zheng, C. Y. Zhang, and Y. Yang, Microstructure and properties of TiN/Fe-based amorphous composite coatings fabricated by reactive plasma spraying. Journal of Alloys and Compounds 785, 206 (2019).

J. Henao, A. Concustell, S. Dosta, G. Bolelli, I. G. Cano, L. Lusvarghi, and J. M. Guilemany, Deposition mechanisms of metallic glass particles by cold gas spraying. Acta Materialia 125, 327 (2017).

J. Su, J. J. Kang, W. Yue, G. Z. Ma, Z. Q. Fu, L. N. Zhu, D. S. She, H. D. Wang, and C. B. Wang, Comparison of tribological behavior of Fe-based metallic glass coatings fabricated by cold spraying and high velocity air fuel spraying. Journal of Non-Crystalline Solids 522, 119582 (2019).

J. G. Gao, Z. H. Tang, C. L. Wang, M. Q. Guo, and Y. J. Cui, Microstructure, mechanical and oxidation characteristics of detonation gun and HVOF sprayed MCrAlYX coatings. Transactions of Nonferrous Metals Society of China 25, 817 (2015).

X. Li, et al., Journal of Non-Crystalline Solids 537, 120018 (2020).

H. Wu, X. D. Lan, Y. Liu, F. Li, W. D. Zhang, Z. J. Chen, X. F. Zai, and H. Zeng, Fabrication, tribological and corrosion behaviors of detonation gun sprayed Fe-based metallic glass coating. Transactions of Nonferrous Metals Society of China 26, 1629 (2016).

P. P. Bandyopadhyay, D. Chicot, B. Venkateshwarlu, V. Racherla, X. Decoopman, and J. Lesage, Mechanics of Materials 53, 61 (2012).

M. S. Gok, International Journal of Physical Sciences 5, 535 (2010).

A. TaoTao, W. Fen, and F. XiaMoing, Science in China Series E: Technological Sciences 52, 1273 (2009).

Y. Wang, C. G. Li, W. Tian, and Y. Yang, Applied Surface Science 255, 8603 (2009).

A. S. Brasunas, NACE Basic Corrosion Course, (NACE, Houston, 1977), p. 12.1

G. A. Greene and C. C. Finfrock, Oxidation of Metals 55, 505 (2001).

H. Singh, D. Puri, S. Prakash, and V. V. Rama Rao, Metallurgical and Materials Transactions A 37A, 3047 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, N., Choubey, V.K. Comparative Evaluation of Oxidation Resistance of Detonation Gun-Sprayed Al2O3–40%TiO2 Coating on Nickel-Based Superalloys at 800 °C and 900 °C. High Temperature Corrosion of mater. 99, 359–373 (2023). https://doi.org/10.1007/s11085-023-10157-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10157-3