Abstract

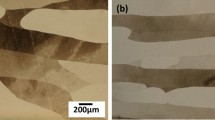

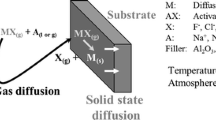

Laboratory corrosion tests, simulating fireside corrosion of 9 mass%Cr steels in an oxyfuel boiler of combusting bituminous 0.6 %S coal, were conducted. Thermodynamic calculation of the tube deposit chemistry indicated that sulfates, instead of carbonates, should be the stable corrosive salts. Specimens of 9 %Cr steels were coated with a synthetic salt mixture of 37.5 m/o Na2SO4–37.5 m/o K2SO4–25 m/o Fe2O3 and were exposed to 57.6 vol%CO2–22.4 %H2O–1.6 %O2–0.16 %SO2–18.2 %N2 at 500–700 °C for 96 h. A two-layered scale of outer “pure” iron oxides and inner oxide/sulfide mixture of Cr and Fe formed on the specimens. The two-layered scale became thick at temperatures where the deposits were fused. The tested steals also underwent internal carburization, with the carbide-zone thickness increasing with increasing temperature for the given exposure time. Growth rate of the carburization zone was much less than the estimation derived from diffusion constants of carbon in α-Fe.

Similar content being viewed by others

References

J. Topper, A. Aumüller, C. Henderson and H. J. Meier, VGB Power Tech 4, 33 (2007).

B. Bordenet, Materials and Corrosion 59, 361 (2008).

B. S. Covino, Jr., S. A. Matthes, and S. J. Bullard, Effect of Oxyfuel Combustion on Superheater Corrosion, CORROSION2008, paper No.08456, (NACE International, Houston, 2008).

M. Montgomery, A. Hjörnhede, and A. Gerhardt, Short-term Corrosion testing in a Burner Rig with Oxyfuel and Conventional Firing, Proceedings of EUROCORR 2009, Nice, 2009.

N. Folkeson, A. Hjörnhede, J. Pettersson, M. Montgomery, M. Bjurman, and J-E. Svensson, Laboratory Investigation of the High Temperature Corrosion of Various Materials in Simulated Oxyfuel and Conventional Coal Firing, Proceedings of EUROCORR 2009, 6–10 September 2009, Nice.

S. Tuurna, P. Pohjanne, S. Yli-Olli, T. Kinnunen, Oxidation Performance of High Temperature Materials under Oxyfuel Conditions, Proceedings of 9th Liege Conference: Materials for Advanced Power Engineer, eds. J. Lecomte-Beckers, Q. Contrepois, T. Beck, and B. Kuhn, 2010, p. 1052.

A. Hjörnhede, M. Montgomery, M. Bjurman, P. Henderson, and A. Gerhardt, Preliminary Experiences with Material Testing at the Oxyfuel Pilot Plant at Schwarzepumpe, Proceedings of 9th Liege Conference: Materials for Advanced Power Engineer, eds. J. Lecomte-Beckers, Q. Contrepois, T. Beck, and B. Kuhn, 2010, p. 1220.

P. Pohjanne, S. Yli-Olli, P. Auerkari, S. Tuurna, P. Jauhiainen, E. Turunen, T. Varis, K. Ruusuvuori, and M. Mäkipää, Fireside Corrosion on Superheater Materials in Oxyfuel Combustion, CORROSION2010, paper No.10200, (NACE International, Houston, 2010).

W. J. Quadakkers, T. Olszewski, J. Piron-Abellan, and L. Singheiser, VDI-Berichte Nr.2102, 2010.

D. Bankiewicz, S. Tuurna, P. Yrjas, and P. Pohjanne, Performance of Superheater Materials in Simulated Oxy-Fuel Combustion Conditions at 650 °C, Proceedings of EUROCORR 2011, Stockholm, 2011.

A. U. Syed, T. Hussain, J. E. Oakey, and N. J. Simms, Fireside Corrosion of Superheater Materials in Oxy-Fired Power Plants, Proceedings of EUROCORR 2011, Stockholm, 2011.

T. Neddemeyer, H. Nitschke, G. Oder, R. S. Neumann, J. Piron, R. Kichheimer, and U. Zeislmair, The Impact of SO2 on the Corrosion Resistance of VM12-SHC Steel in CO2 Rich Flue Gas, Proceedings of EUROCORR 2011, Stockholm, 2011.

Thermodynamic data base MALT 2, The Japanese Society of Thermo-Heat Measurement, supplied by Kagakugijutsusha Co., 1992.

C. Cain and W. Nelson, Transactions of the ASME: Journal of Engineering for Power, Series A 83, 768 (1961).

N. Otsuka, Laboratory Corrosion Test Results Simulating Fireside Corrosion of Austenitic Superheater and Reheater Tube Materials in Advanced USC Boilers, Proceedings of EUROCORR 2009, paper no. 7767, Nice, 2009.

N. Otsuka, Materials Science Forum 696, 206 (2011).

Internal Report of the Sumitomo Metal Industries, Ltd.

R. A. Rapp and Y. S. Zhang, JOM 46, 47 (1994).

R. B. McLellan, M. Rudee and T. Ishibachi, Transactions of the AIME 233, 1938 (1965).

D. J. Young, in Shreir’s Corrosion, eds. R. A. Cottis, M. J. Graham, R. Lindsay, S. B. Lyon, J. A. Richardson, J. D. Scantlebury, and F. H. Stott, Vol. 1 Elsevier, 2010, p. 274.

THERMO-CALC Calculation for the T91 Steel, the Chemical Composition is Shown in Table 2. Data Base: TCFE6.

C. T. Fujii and R. A. Meussner, Journal of the Electrochemical Society 114, 435 (1967).

J. E. Antill, K. A. Peakall and J. B. Warburton, Corrosion Science 8, 689 (1968).

C. S. Giggins and F. S. Pettit, Oxidation of Metals 14, 363 (1980).

Acknowledgments

The author wishes to thank S. Ishibashi and Y. Tabata for their contribution in conducting the laboratory experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Otsuka, N. Carburization of 9 %Cr Steels in a Simulated Oxyfuel Corrosion Environment. Oxid Met 80, 565–575 (2013). https://doi.org/10.1007/s11085-013-9396-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-013-9396-9