Abstract

We investigated the oligomerization of solid valine and the stabilities of valine and valine peptides under conditions of high temperature (150–200 °C) and high pressure (50–150 MPa). Experiments were performed under non-aqueous condition in order to promote dehydration reaction. After prolonged exposure of monomeric valine to elevated temperatures and pressures, the products were analyzed by liquid chromatography mass spectrometry comparing their retention times and masses. We identified linear peptides that ranged in size from dimer to hexamer, as well as a cyclic dimer. Previous studies that attempted abiotic oligomerization of valine in the absence of a catalyst have never reported valine peptides larger than a dimer. Increased reaction temperature increased the dissociative decomposition of valine and valine peptides to products such as glycine, β-alanine, ammonia, and amines by processes such as deamination, decarboxylation, and cracking. The amount of residual valine and peptide yields was greater at higher pressures at a given temperature, pressure, and reaction time. This suggests that dissociative decomposition of valine and valine peptides is reduced by pressure. Our findings are relevant to the investigation of diagenetic processes in prebiotic marine sediments where similar pressures occur under water-poor conditions. These findings also suggest that amino acids, such as valine, could have been polymerized to peptides in deep prebiotic marine sediments within a few hundred million years.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The abiotic polymerization of amino acids may have been essential for the formation of primordial oligopeptides on early Earth (Oparin 1957). Many researchers have suggested that various amino acids could have formed on early Earth (Huber and Wächtershäuser 2006; Furukawa et al. 2009; Goldman et al. 2010) or could have been delivered to early Earth (Cronin and Moore 1971; Hennet et al. 1992; Marshall 1994; Bernstein et al. 2002; Pizzarello et al. 2003). The oligomerization of amino acids has been investigated in many studies that aimed to simulate environments, such as submarine hydrothermal systems and tidal flats, considered to be suitable for the origin of life (Lahav et al. 1978; Huber and Wächtershäuser 1998; Bujdák and Rode 1999; Imai et al. 1999; Kawamura et al. 2005; Cleaves et al. 2009). However, the decomposition rate of peptides in hydrothermal fluids is significantly related to reaction temperature. For example, amounts of peptides can reduce by two orders of magnitude within 25 h at 260 °C (Lemke et al. 2009). Also, the decomposition of amino acids and peptides was likely promoted in shallow aqueous environments, in which strong photolytic conditions is expected on early Earth (Kappler et al. 2005).

Nakazawa and colleagues proposed that amino acids were polymerized by geothermal heating and dehydration of marine sediments during diagenesis (Nakazawa et al. 1993; Nakazawa 2006; Nakazawa 2008). In the water column of the present ocean and in shallow sediments, oxidation and biodegradation of organic compounds, including amino acids, are the main processes of organic decomposition (Killops and Killops 2005). The absence of biotic degradation and likelihood of extreme depletion of oxygen in the prebiotic atmosphere and ocean (Kasting 1993) suggest that prebiotic amino acids may have been able to survive for extended periods in the water column of Hadean ocean. Photolytic reactions may have decomposed organic matter on the surface of early Earth, when the ozone layer was absent in the atmosphere. However, the photolytic reactions might have been restricted to the surface layer of ocean water because of significant attenuation of UV in the ocean water (Kappler et al. 2005). Therefore, organic compounds in prebiotic ocean waters were most probably did not experience significant photolytic decompositions. Then they were introduced into marine sediments by adsorption onto clays (Bernal 1949; Hedges and Hare 1987; Lambert 2008). These organic-rich sediments would have subsequently been subjected to diagenetic processes involving decreases in the pore spaces of sediments caused by compaction resulting from elevated pressure. Normal diagenesis occurs at temperatures below approximately 100 °C (Killops and Killops 2005). Given the present geothermal gradient (approximately 0.03 °C/m), this temperature range corresponds to pressures below 90 MPa. This pressure range is a maximum estimate for Hadean sediment if geothermal gradient in marine sediments of the era was higher than that at present (Percival 1994).

During diagenesis, most free water is expelled from marine sediments during compaction, while significant amounts of amino acids and other organic molecules remain in the sediments adsorbed by minerals. This process could create amino acid-condensed conditions in sediments after the water seeps out. Given that the oligomerization of amino acids is a dehydration reaction, such a water-poor environment may have provided feasible conditions for the production of oligopeptides.

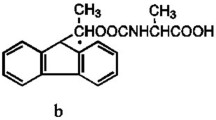

Several studies have investigated peptide formation under conditions that simulate compressed marine sediments. For instance, by applying high temperature (150 °C) and pressure (5–100 MPa) to solid monomeric glycine, Ohara et al. (2007) demonstrated the formation of glycine peptides as long as a decamer, which is the longest peptide reported to have been synthesized in the absence of a catalyst. Their study emphasized the importance of pressure in driving the abiotic polymerization of amino acids. Otake et al. (2011) reported the formation of alanine peptides as long as pentamers under much higher temperature (180–440 °C) and pressure (1.0–5.5 GPa) conditions than those used by Ohara et al. (2007). Otake et al. (2011) suggested that high pressure inhibits the decarboxylation of amino acids, thus increasing the stability of amino acids and peptides. However, the temperatures and pressures used in their study were much higher than those in diagenetic environments. Moreover, the effects of pressure on peptide formation have never been examined for amino acids other than glycine and alanine. Valine, one of the 20 coded amino acids found in proteins, is a fairly simple amino acid with an alkyl side chain. The significance of the inclusion of valine in prebiotic peptides has been suggested (Oba et al. 2005; Ikehara 2005; Ikehara 2009). Therefore, we investigated the effects of elevated temperature and pressure on the oligomerization reactions of valine and the stabilities of monomeric and polymeric valine under conditions of temperature and pressure that simulate sub-seafloor conditions.

We conducted isothermal heating experiments on compressed solid valine enclosed in a capsule under pressure conditions corresponding to late diagenesis in the present Earth (e.g., 50–150 MPa). Although it is not necessarily realistic to infer that oligomerization of amino acid passed a solid state, solid valine was used as an extreme case in this study in order to investigate its stability and oligomerization in sediments. To accelerate the reactions, we used temperatures as high as 250 °C, which are higher than those at which diagenesis occurs.

Materials and Methods

Temperature and Pressure Treatments

Compressed solid valine was heated in a high-temperature and high-pressure reactor in which water was used as a pressure medium. Experiments were conducted under isothermal and isobaric conditions at 150–250 °C and 50–150 MPa for up to 192 h. The starting material was 100 mg of L-valine powder (more than 99.0 % pure; Wako Pure Chemical Industries Ltd.). The starting material was enclosed in a gold capsule (99.95 % purity, 0.2 mm thick) with a 5.5 mm external diameter and external length of 20 mm. The capsule was pretreated by heating at 800 °C for 5 h to remove any organic contaminations before encapsulation. After filling the gold capsule with monomeric valine, it was then closed by arc-welding after eliminating air by pressing the capsule.

The pressure of the sample was raised to a selected value before increasing the temperature. A run was considered to start (i.e., t = 0) when the temperature reached a selected value, and considered to end when heating was stopped. The experimental system was cooled to near room temperature within 10 min, followed by releasing pressure. No change in the weight of the gold capsule and its contents were observed between the beginning and end of any of the experiments. This indicates that the integrity with which each gold capsule was sealed was maintained without any leakage during the heating experiments.

Analyses of Run Products

A high performance liquid chromatograph (HPLC) coupled to a tandem mass spectrometer (LC/MS-MS) was used to identify and quantify the peptides produced. A portion of the experimental product (~0.5 mg) was collected and dissolved into 1 ml water: acetonitrile (95:5 vol/vol). A portion of the sample solution (5 μl) was injected into the LC/MS instrument (2695 and Quattro Micro API; Waters Corp.), which used a reversed-phase column (Atlantis T3: 3 μm, 2.1 × 130 mm; Waters Corp.) maintained at 30 °C for separation. A gradient-mixing program involving two eluants (A: 10 mmol/l ammonium formate (pH: 3); B: acetonitrile; total flow rate: 0.2 ml/min) were used to separate valine peptides. All water used was ultrapure water prepared using Simplicity UV (Millipore) purification system. Valine dimer (Val2), trimer (Val3), tetramer (Val4), pentamer (Val5), hexamer (Val6), and cyclic dimer (diketopiperazine; ValDKP) were identified by the positive mode of electrospray ionization (ESI). Capillary voltage, source temperature, and desolvation temperature were set at 3.5 kV, 110 °C, and 350 °C, respectively. Desolvation and cone gas flow rates were fixed at 600 and 50 l/h, respectively. ESI is a non-destructive ionization technique that generally produces an ion by the addition of a proton to the intact compound (m/z = [M + H]+), and so the protonated intact ions of each peptide were monitored by the single ion resonance mode. Identification was conducted by comparisons with standard peptides in terms of their retention time on the mass chromatogram of their protonated intact ion. The Val2 standard was purchased from MP Biomedicals LLC, and Val3, Val4, and ValDKP were purchased from Bachem AG. Commercial standards of Val5 and Val6 with high purity are not available, and thus a Val4 standard, which contains minor amounts of Val5 and Val6, was used for identification of Val5 and Val6. The identification of Val5 and Val6 in the commercial Val4 standard was conducted using the product ion scan mode of the tandem mass spectrometer by checking the combinations of product ions from these precursor ions (m/z = 514 for Val5; m/z = 613 for Val6). The amounts of Val5 and Val6 in the standards were too small to allow yields of Val5 and Val6 in the samples to be quantified. Yields of products and the levels of residual monomeric valine were calculated assuming that there was no weight loss when products were weighed for analysis.

A different HPLC system (L-7100 system; Hitachi Ltd.) was used for the analyses of amino acids, amines and ammonia. A portion of run products (~0.5 mg) was dissolved in 1 ml of 0.02 mol/l HCl solution prepared by diluting protein-sequence grade HCl (Sigma-Aldrich Co.) with pure water. A portion of the sample solution (20 μl) was injected into the HPLC system, which was equipped with a strong cation exchange column (#2619 PH, 5 μm, 4.0 × 150 mm; Hitachi Ltd.) maintained at 60 °C. Three types of eluants were used for the separation of amino acids. Eluant A was sodium citrate buffer solution containing 11 % (vol/vol) ethanol (pH = 3.3). Eluant B was sodium citrate buffer solution with 5.4 wt % sodium chloride (pH = 4.9). Eluant C was 0.2 mol/l NaOH solution. These eluents were mixed in the HPLC by the following linear gradient program, using a constant flow rate (0.4 ml/min): 0–6 min, A/B/C = 100/0/0; 41–52 min, A/B/C = 0/100/0; 52.1–59 min, A/B/C = 0/0/100. After their separation by chromatography, amino acids, amines, and ammonia were derivatized in the presence of reaction solutions D, E, and F at 60 °C. Solution D was 0.6 mol/l NaOH, solution E comprised a mixture of boric acid with sodium hypochlorite and polyoxyethylene lauryl ether, and solution F comprised a mixture of boric acid with o-phthalaldehyde, 2-mercaptoethanol and polyoxyethylene lauryl ether. The derivatized products were detected using a fluorometer (L-7485; Hitachi Ltd.) with excitation and emission wavelengths set to 340 nm and 450 nm, respectively. The concentrations of derivatized products were determined by comparisons with standard test solutions.

The recovery of residual monomeric valine was calculated as 100 × (moles of monomeric valine in the run products)/(moles of monomeric valine in starting material). The yields of peptides were calculated as 100 × (moles of a peptide detected in the run product)/(the maximum moles of the peptide that can be produced from the initial amount of valine). For example, assuming that the dimerization reaction was complete, the maximum amount of Val2 that could have been produced from 0.85 mmol (i.e., 100 mg) of monomeric valine is ½ × 0.85 mmol.

Results

Products

Chromatograms of some run products revealed that the products contain valine peptides, which were identified by comparing their retention times with those of standards (Fig. 1). Such an approach robustly identifies experimental production of valine peptides. The peptides identified from all the experimental products include linear peptides ranging in size from dimer to hexamer (Val2, Val3, Val4, Val5, and Val6), as well as a cyclic dimer peptide (ValDKP) (Fig. 1).

Single ion chromatograms of a peptide standard and a sample following incubation of solid valine at 200 °C under a pressure of 100 MPa for 48 h. The standard is composed of mixture of Val2, ValDKP, Val3, Val4, Val5, and Val6. The m/z values represent monitored mass-to-charge ratios of the protonated intact ion for each valine peptide. The target peptides was identified by the presence of peaks in each mass chromatogram of a sample having the same retention time as a standard

Ammonia, ethylamine, methylamine, glycine, and β-alanine were also identified as products following exposure to 200 °C and 100 MPa for 192 h (Fig. 2). Under these conditions, the production of ammonia and glycine gives yields as high as 20 % and 0.015 %, respectively, accompanied by decreased levels of residual monomeric valine (Fig. 3).

At 200 °C, the products have a viscose, paste-like appearance as reaction time increases. The gold capsules had progressively expanded after the experiments in accordance with reaction time. Such changes were not observed in products of experiments conducted at lower temperatures.

Effects of Pressure

The effects of different pressure conditions (50, 100, and 150 MPa) at 200 °C on both the yields of valine peptides and the recovery of residual monomeric valine are reported in Fig. 4. At all three pressures tested, the recovery of residual valine continuously decreased in a sigmoidal fashion to 0.16 %–1.8 % after 192 h (Fig. 4). The rate of decomposition of monomeric valine was lowest at 150 MPa and highest at 50 MPa. The yields of linear peptides reached a maximum 48 h after commencing the reaction, whereafter both the recovery of monomeric valine and the yields of valine peptides decreased slightly under all of the pressure conditions tested. For example, yields of Val2 reached a maximum of 0.19 %–0.36 % at 48 h, but decreased to 0.07 %–0.16 % after 192 h (Fig. 4). The lowest yields of products in each reaction time always occurred at the lowest pressures tested. Yields of ValDKP were always higher than those of linear peptides, and were even higher than the levels of monomeric valine recovered after 48 h at 50 MPa and 100 MPa, and after 96 h at 150 MPa.

Yields of peptides and levels of residual valine following incubation of solid valine under three different pressure conditions at 200 °C. The pressures tested were (a) 50 MPa, (b) 100 MPa, and (c) 150 MPa. The yields of residual valine were calculated as 100 × (moles of valine in run products)/(moles of valine in starting material). The yields of peptides were calculated as 100 × (moles of a peptide detected in a run product)/(maximum moles of the peptide that can be produced from the initial amount of valine). Error bars correspond to a 50 % measurement error

Figure 5 shows the recoveries of residual valine and yields of peptides after 192 h reaction at the three pressures tested at 200 °C. Levels of residual monomeric valine recovered after 192 h of reaction were ~10–100 times lower than the initial amount (Fig. 5). The observation that more residual monomeric valine remained after exposure to higher pressures, such as 150 MPa, than at lower pressures suggested a role for pressure in the decomposition of monomeric valine (Fig. 5). Higher yields of Val2, Val3, and Val4 were also found at 150 MPa than at 50 MPa. In contrast, yields of ValDKP decreased with increases in pressure (Fig. 5).

Effects of Temperature

Figures 4b and 6 show the time-dependent recoveries of residual valine and yields of valine peptides at 150 °C (Fig. 6a), 175 °C (Fig. 6b), and 200 °C (Fig. 4b). After exposure to 150 °C at 100 MPa for 192 h, >99 % of the monomeric valine remained unreacted, corresponding to the low yields of Val2 (0.0023 %) and Val3 (0.00023 %) (Fig. 6a). On the other hand, heating to 175 °C for the same period was associated with the reaction of 11 % of the monomeric valine, corresponding with increases in Val2 and Val3 yields to 0.029 % and 0.0024 %, respectively (Fig. 6b). In the case of experiments at 200 °C for 192 h, the recovery of valine decreased to < 1 % (Fig. 4b). The amount of valine peptides initially increased at 24 or 48 h and then subsequently decreased. The highest yield of Val2 was observed at 200 °C (0.34 %).

Figure 7 shows the temperature dependence of recovery of residual monomeric valine and valine peptides generated at 100 MPa for 48 h. The recovery of residual valine decreased substantially at temperatures higher than 175 °C, and levels of monomeric valine were below the limits of detection at 250 °C. The yields of peptides increased with reaction temperature up to 200 °C at 100 MPa for 48 h of reaction. With the exception of ValDKP, the yields of all peptides fell below the limits of detection at 225 °C. At 250 °C, the yield of ValDKP fell below the detection limit. The products became yellow and exhibited a viscose, paste-like appearance as reaction time progressed. The gold capsules were expanded after the experiments in accordance with the reaction time. These observations suggest that enhanced decomposition reaction rates of valine and its peptides occurred at higher temperatures.

Discussion

Factors Promoting the Formation of Valine Peptides Under Conditions of High Temperature and Pressure

Increases in the yields of ammonia, ethylamine, methylamine and glycine occurred at the expense of a decrease in the residual amount of monomeric valine (Fig. 3). This indicates that the dissociative decomposition of monomeric valine and valine peptides (e.g., deamination and decarboxylation) progressed throughout the course of these runs. Deamination and decarboxylation of amino acids have been found in previous studies that investigated thermal decomposition of amino acids (Simmonds et al. 1972; Sato et al. 2004). The dissociative decomposition of valine with the formation of ammonia and amines suggests the formation of carboxylic acids and carbon dioxide (Fig. 8). The observed expansion of sample capsules after the experiments is consistent with the formation of these gaseous products.

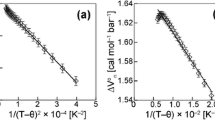

Pressure is known to affect the rates of reactions associated with a change in the activation volume (Asano and Le Noble 1978; Vaneldik et al. 1989; House 2007). The activation volume represents the difference between the sum of the partial molar volumes of reactants and the molar volume of the transition state. In general, positive activation volumes are associated with bond cleavage and negative activation volumes are associated with bond formation (Asano and Le Noble 1978; Vaneldik et al. 1989). It is reasonable to assume that activation volumes during dissociative decompositions of valine and valine peptides are positive, similar to those of many dissociative decompositions of organic compounds (Asano and Le Noble 1978). Elevated pressures tend to decelerate reaction rates when activation volumes are positive, thus reducing the rates of dissociative decomposition (Asano and Le Noble 1978; Vaneldik et al. 1989). This effect appears to explain our results, which indicate that valine recoveries and peptide yields increased with pressure (Figs. 4 and 5).

In the experimental system that we used, the oligomerization reaction competes with decomposition (Fig. 8). For example, peptides such as Val2 are subject to both thermal decomposition and further oligomerization (Fig. 8). Therefore, reduced decomposition of valine and its shorter peptides might increase the amount of reactants available for oligomerization.

The increase in Val2/ValDKP ratios with elevated pressures (Fig. 5) is another important result that emerged from our study. Although the thermodynamic data needed to examine the changes in the reaction volume that accompany the transition of Val2 to ValDKP is not available for the experimental conditions we used, our results suggest that elevated pressure reduces the amount of ValDKP formed from Val2 because dissociative decompositions of the amino and carbonyl groups in ValDKP need more activation energy than that needed for the deamination and decarboxylation of valine and its linear peptides.

The yields of the quantified products suggest that neither peptide-forming oligomerization of valine nor dissociative decomposition of valine were the major reactions occurring in our study. Browning of samples incubated at high temperatures suggests that one of the potential major reactions was the Maillard reaction, which has been shown to produce melanoidins in high-pressure heating experiments on glycine (Ohara et al. 2007).

Temperature had a more substantial effect on the yields of peptides and the recovery of residual valine than pressure (Figs. 5 and 7). For example, the decomposition rates of valine at 100 MPa differed substantially at different temperatures between 150 °C and 200 °C (Figs. 4b, 6, and 7). Valine decomposition rates increase with temperature, in particular when temperatures exceed 175 °C. Although rates of peptide production also increase with increases in temperature (Figs. 4b, 6, and 7), this is partially offset by increased rates of peptide decomposition under high-temperature conditions. The increase of valine decomposition rates with elevated temperature is consistent with previous studies that investigated the decomposition of amino acids and the thermal cracking of hydrocarbons (Behar and Vandenbroucke 1996; Sato et al. 2004; Cox and Seward 2007; Lemke et al. 2009). However, in the present study, the effects of elevated pressure reduced these decompositions (Fig. 5).

Implications for Understanding the Abiotic Formation of Peptides on Early Earth

Valine peptides as large as hexamers (Val2, Val3, Val4, Val5, and Val6) were synthesized from monomeric valine in our experiments in the absence of a catalyst. Until now, the longest linear valine peptide generated abiotically has been the Val2 dimer, and its synthesis required activation by catalysts (Bujdák and Rode 1999; Plankensteiner et al. 2002; Plankensteiner et al. 2005; Reiner et al. 2006). Therefore, ours is the first report to demonstrate the abiotic formation of valine peptides longer than a dimer. Whereas previous studies simulated conditions in tidal flats by heating and drying valine solutions at lower temperature (at 85 °C) and ambient pressure (Bujdák and Rode 1999; Plankensteiner et al. 2002; Plankensteiner et al. 2005), we applied higher temperatures (150–200 °C) and pressures (50–150 MPa) to valine. Whereas heating allowed valine to overcome the activation energy to form longer peptides, high pressure might have decreased the thermal decomposition of valine and its peptides.

No previous experimental study has reported the oligomerization of valine monomers to form peptides under conditions similar to those of a submarine hydrothermal environment, which is considered a potential geological setting in which abiotic polymerization of amino acids may have occurred (Imai et al. 1999; Kawamura et al. 2005). Amino acids and peptides decompose rapidly under conditions that simulate modern submarine hydrothermal environments (typically at 200–300 °C under ~10 MPa) (Miller and Bada 1988; Lemke et al. 2009). Another challenge associated with submarine hydrothermal systems for amino acid oligomerization may be the consumption of dimer to form DKP. The formation of DKP is calculated to be thermodynamically favored at temperatures that exceed 200 °C (Shock 1992), although this may depend on fluid pH. Our results suggest that pressure may be able to reduce the DKP formation under diagenetic conditions.

In marine sediments, the sedimentation rate affects the pressure and temperature conditions of buried sediment (Boggs 2009) and the duration of a given set of conditions. After continuous sedimentation, the amino acids in sediments would experience higher temperature and pressure conditions. A convergent margin (e.g., an accretionary prism) may provide higher pressures than a typical geothermal gradient (Giunchi and Ricard 1999). Such an environment might be more conducive to the oligomerization of amino acids by reducing the decomposition of amino acids and peptides. Some of these peptides may not have been suducted, remained in the accretion prism, and then have been eluted into the prebiotic ocean. It is noteworthy that a modern analogue of such processes has been reported from the accretionary wedge at Nankai, Japan (Doan et al. 2011).

Comparison with the previous report describing the effects of pressure on glycine peptide formation (Ohara et al. 2007) reveals a large difference in the rates of decomposition of valine and glycine at 150 °C under 100 MPa. Structurally, glycine and valine differ only in their side chains. Studies that investigated the thermal decomposition of amino acids and paraffin demonstrated a relationship between decreased reaction rates and increasing molecular sizes (Voge and Good 1949; Sato et al. 2004). This suggests that, during diagenesis, valine peptides may be formed and stabilized deeper beneath the seafloor than glycine peptides. Different requirements for the oligomerization of different amino acids may be of value in better understanding prebiotic chemistry adapted to conditions of high pressure and temperature.

Conclusion

Valine peptides as large as hexamers (Val2, Val3, Val4, Val5, and Val6) were formed by heating compressed solid monomeric valine under a range of elevated temperature (150–200 °C) and pressure (50–150 MPa) conditions. Increased rates of peptide formation at higher temperatures were accompanied by the decomposition of both monomeric valine and valine peptides to generate glycine, ammonia, and amines. The simultaneous formation of glycine, ammonia, and amines indicates the decomposition of valine by dissociative reactions, such as deamination, decarboxylation, and cracking. Decomposition rates of valine and peptides were reduced by pressure, resulting in increased peptide yields when pressure was increased. The higher yields of monomeric valine and valine peptides at higher pressures may be the result of the decrease in the dissociative decomposition of valine and its peptides. These results suggest that the diagenesis of prebiotic marine sediments enriched in amino acids may have provided suitable conditions for prebiotic peptide formation under appropriate conditions of pressure and dehydration.

References

Asano T, Le Noble WJ (1978) Activation and reaction volumes in solution. Chem Rev 78:407–489

Behar F, Vandenbroucke M (1996) Experimental determination of the rate constants of the n-C25 thermal cracking at 120, 400, and 800 bar: implications for high-pressure/high-temperature prospects. Energy Fuel 10:932–940

Bernal JD (1949) The physical basis of life. Proc Phys Soc A 62:537–558

Bernstein MP, Dworkin JP, Sandford SA, Cooper GW, Allamandola LJ (2002) Racemic amino acids from the ultraviolet photolysis of interstellar ice analogues. Nature 416:401–403

Boggs SJ (2009) Petrology of sedimentary rocks. Cambridge University Press, Cambridge

Bujdák J, Rode BM (1999) Silica, alumina and clay catalyzed peptide bond formation: enhanced efficiency of alumina catalyst. Orig Life Evol Biosph 29:451–461

Cleaves HJ, Aubrey AD, Bada JL (2009) An evaluation of the critical parameters for abiotic peptide synthesis in submarine hydrothermal systems. Orig Life Evol Biosph 39:109–126

Cox JS, Seward TM (2007) The reaction kinetics of alanine and glycine under hydrothermal conditions. Geochim Cosmochim Acta 71:2264–2284

Cronin JR, Moore CB (1971) Amino acid analyses of Murchison, Murray, and Allende carbonaceous chondrites. Science 172:1327–1329

Doan ML, Conin M, Henry P, Wiersberg T, Boutt D, Buchs D, Saffer D, McNeill LC, Cukur D, Lin WR (2011) Quantification of free gas in the Kumano fore-arc basin detected from borehole physical properties: IODP NanTroSEIZE drilling Site C0009. Geochemistry Geophysics Geosystems 12: dio:10.1029/2010gc003284

Furukawa Y, Sekine T, Oba M, Kakegawa T, Nakazawa H (2009) Biomolecule formation by oceanic impacts on early Earth. Nat Geosci 2:62–66

Giunchi C, Ricard Y (1999) High-pressure/low-temperature metamorphism and the dynamics of an accretionary wedge. Geophys J Int 136:620–628

Goldman N, Reed EJ, Fried LE, Kuo IFW, Maiti A (2010) Synthesis of glycine-containing complexes in impacts of comets on early Earth. Nat Chem 2:949–954

Hedges JI, Hare PE (1987) Amino acid adsorption by clay minerals in distilled water. Geochim Cosmochim Acta 51:255–259

Hennet RJC, Holm NG, Engel MH (1992) Abiotic synthesis of amino acids under hydrothermal conditions and the origin of life: a perpetual phenomenon. Naturwissenschaften 79:361–365

House JE (2007) Principles of chemical kinetics. Elsevier, Burlington

Huber C, Wächtershäuser G (1998) Peptides by activation of amino acids with CO on (Ni, Fe)S surfaces: implications for the origin of life. Science 281:670–672

Huber C, Wächtershäuser G (2006) α-hydroxy and α-amino acids under possible hadean, volcanic origin-of-life conditions. Science 314:630–632

Ikehara K (2005) Possible steps to the emergence of life: the [GADV]-protein world hypothesis. Chem Rec 5:107–118

Ikehara K (2009) Pseudo-replication of [GADV]-proteins and origin of life. Int J Mol Sci 10:1525–1537

Imai E, Honda H, Hatori K, Brack A, Matsuno K (1999) Elongation of oligopeptides in a simulated submarine hydrothermal system. Science 283:831–833

Kappler A, Pasquero C, Konhauser KO, Newman DK (2005) Deposition of banded iron formations by anoxygenic phototrophic Fe(II)-oxidizing bacteria. Geology 33:865–868

Kasting JF (1993) Earth's early atmosphere. Science 259:920–926

Kawamura K, Nishi T, Sakiyama T (2005) Consecutive elongation of alanine oligopeptides at the second time range under hydrothermal conditions using a microflow reactor system. J Am Chem Soc 127:522–523

Killops S, Killops V (2005) Introduction to organic geochemistry. Blackwell Publishing, Malden

Lahav N, White D, Chang S (1978) Peptide formation in prebiotic era: thermal condensation of glycine in fluctuating clay environments. Science 201:67–69

Lambert JF (2008) Adsorption and polymerization of amino acids on mineral surfaces: a review. Orig Life Evol Biosph 38:211–242

Lemke KH, Rosenbauer RJ, Bird DK (2009) Peptide synthesis in early Earth hydrothermal systems. Astrobiology 9:141–146

Marshall WL (1994) Hydrothermal synthesis of amino acids. Geochim Cosmochim Acta 58:2099–2106

Miller SL, Bada JL (1988) Submarine hot springs and the origin of life. Nature 334:609–611

Nakazawa H (2006) Origin of life scenario written by the earth. Shin-Nihon Shuppan Ltd., Tokyo

Nakazawa H (2008) Origin and evolution of life: endless ordering of the Earth’s light elements. In International Symposium on Origin and Evolution of Natural Diversity. Hokkaido University, Sapporo, pp 13–19

Nakazawa H, Yamada H, Hashizume H (1993) Origin of life in the Earth’s crust, a hypothesis: probable chemical evolution synchronized with the plate tectonics of the early Earth. Viva Origino 21:213–222

Oba T, Fukushima J, Maruyama M, Iwamoto R, Ikehara K (2005) Catalytic activities of [GADV]-peptides. Orig Life Evol Biosph 35:447–460

Ohara S, Kakegawa T, Nakazawa H (2007) Pressure effects on the abiotic polymerization of glycine. Orig Life Evol Biosph 37:215–223

Oparin AI (1957) The origin of life on the earth. Oliver & Boyd, Edinburgh

Otake T, Taniguchi T, Furukawa Y, Kawamura F, Nakazawa H, Kakegawa T (2011) Stability of amino acids and their oligomerization under high-pressure conditions: implications for prebiotic chemistry. Astrobiology 11:799–813

Percival J (1994) Archean high-grade metamorphism. In: (ed. KC Condie) Archean crustal evolution, Elsevier, Amsterdam, pp 357–410

Pizzarello S, Zolensky M, Turk KA (2003) Nonracemic isovaline in the Murchison meteorite: chiral distribution and mineral association. Geochim Cosmochim Acta 67:1589–1595

Plankensteiner K, Reiner H, Rode BM (2005) Catalytic effects of glycine on prebiotic divaline and diproline formation. Peptides 26:1109–1112

Plankensteiner K, Righi A, Rode BM (2002) Glycine and diglycine as possible catalytic factors in the prebiotic evolution of peptides. Orig Life Evol Biosph 32:225–236

Reiner H, Plankensteiner K, Fitz D, Rode BM (2006) The possible influence of L-histidine on the origin of the first peptides on the primordial earth. Chem Biodivers 3:611–621

Sato N, Quitain AT, Kang K, Daimon H, Fujie K (2004) Reaction kinetics of amino acid decomposition in high-temperature and high-pressure water. Ind Eng Chem Res 43:3217–3222

Shock EL (1992) Stability of peptides in high-temperature aqueous solutions. Geochim Cosmochim Acta 56:3481–3491

Simmonds PG, Shulman GP, Ratcliff MA, Medley EE (1972) Thermal decomposition of aliphatic monoamino-monocarboxylic acids. Anal Chem 44:2060–2066

Vaneldik R, Asano T, Lenoble WJ (1989) Activation and reaction volumes in solution. 2. Chem Rev 89:549–688

Voge HH, Good GM (1949) Thermal cracking of higher paraffins. J Am Chem Soc 71:593–597

Acknowledgements

The authors thank S. Ohara and K. Kawamura for helpful discussions. This study was supported by the Global COE program (Global Education and Research Center for Earth and Planetary Dynamics) of Tohoku University and by grants-in-aid for scientific research from the Japan Society for the Promotion of Science (JSPS) to T.K. (21244080), Y.F. (21840013), and H.N. (21340162).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Furukawa, Y., Otake, T., Ishiguro, T. et al. Abiotic Formation of Valine Peptides Under Conditions of High Temperature and High Pressure. Orig Life Evol Biosph 42, 519–531 (2012). https://doi.org/10.1007/s11084-012-9295-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11084-012-9295-0