Abstract

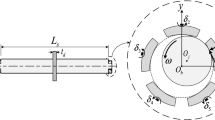

This work brings an overview of the nonlinear dynamics of four-segment tilting pad journal bearings (TPJB) in load-between-pads configuration supported on flexible pivots. We focus primarily on analysing the sub-synchronous motion of statically unloaded pads, also called pad fluttering. In this particular case, the motion deviates between chaotic and periodic due to 1:4, 1:5, 1:6 and 1:7 internal resonances. The response is analysed with bifurcation diagrams and characterised with estimates of the largest Lyapunov exponents. Unlike previous works, we show that pad fluttering disappears at relative eccentricities lower than 0.34. This behaviour is enabled due to a fixed point trajectory that is not predicted by analysing static equilibria. The observation is crucial for high-speed rotating machinery supported on TPJBs, including pinions in multi-stage compressors and microturbines. The analysis is performed using a verified computational model which includes fluid-structure interaction and potential Hertzian contacts between individual parts of the TPJB. This model exploits local and auxiliary coordinate systems for a straightforward description of acting forces. Furthermore, we provide a detailed step-by-step discussion regarding the model formulation employing the finite difference method to solve hydrodynamic lubrication.

Similar content being viewed by others

Data availability statement

The datasets generated during and analysed during the current study are available from the corresponding author on reasonable request.

References

Daniel, G., Cavalca, K.: Investigation of the influence of thermal effects in the dynamic coefficients of a tilting pad journal bearing. In: Institution of Mechanical Engineers—10th International Conference on Vibrations in Rotating Machinery, pp. 479–489 (2012)

Dimond, T.W., Younan, A.A., Allaire, P.E.: Comparison of tilting-pad journal bearing dynamic full coefficient and reduced order models using modal analysis. In: Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, pp. 1043–1053 (2009). https://doi.org/10.1115/GT2009-60269

Yan, Z., Wang, L., Qiao, G., Zheng, T.: An analytical model for complete dynamical coefficients of a tilting-pad journal bearing. Tribol. Int. 43(1), 7–15 (2010). https://doi.org/10.1016/j.triboint.2009.03.010

Flack, R.D., Zuck, C.J.: Experiments on the stability of two flexible rotors in tilting pad bearings. Tribol. Trans. 31(2), 251–257 (1988). https://doi.org/10.1080/10402008808981820

Brancati, R., Rocca, E., Russo, R.: Non-linear stability analysis of a rigid rotor on tilting pad journal bearings. Tribol. Int. 29(7), 571–578 (1996). https://doi.org/10.1016/0301-679X(96)00003-5

Haugaard, A.M., Santos, I.F.: Stability of multi orifice active tilting-pad journal bearings. Tribol. Int. 43(9), 1742–1750 (2010). https://doi.org/10.1016/j.triboint.2010.04.013

Hargreaves, D., Fillon, M.: Analysis of a tilting pad journal bearing to avoid pad fluttering. Tribol. Int. 40, 607–612 (2007). https://doi.org/10.1016/j.triboint.2005.11.019

Lund, J.W.: Spring and damping coefficients for the tilting-pad journal bearing. ASLE Trans. 7(4), 342–352 (1964). https://doi.org/10.1080/05698196408972064

Adams, M., Payandeh, S.: Self-excited vibration of statically unloaded pads in tilting-pad journal bearings. J. Tribol. 105(3), 377–383 (1983). https://doi.org/10.1115/1.3254616

Yang, S.H., Kim, C., Lee, Y.-B.: Experimental study on the characteristics of pad fluttering in a tilting pad journal bearing. Tribol. Int. 39(7), 686–694 (2006). https://doi.org/10.1016/j.triboint.2005.05.006

Pennacchi, P., Vania, A., Chatterton, S., Pesatori, E.: Case history of pad fluttering in a tilting-pad journal bearing, in: Proceedings of ASME Turbo Expo 2010: Power for Land, Sea and Air, pp. 1–7 (2010). https://doi.org/10.1115/GT2010-22946

Ikeda, K., Hirano, T., Yamashita, T., Mikami, M., Sakakida, H.: An experimental study of static and dynamic characteristics of a 580mm(22.8in.) diameter direct lubrication tilting pad journal bearing. J. Tribol. 128(1), 146–154 (2006). https://doi.org/10.1115/1.2114929

Dimond, T., Younan, A., Allaire, P.: A review of tilting pad bearing theory. Int. J. Rotat. Mach. 2011, 1–23 (2011). https://doi.org/10.1155/2011/908469

Nicholas, J.C., Gunter, E.J., Allaire, P.E.: Stiffness and damping coefficients for the five-pad tilting-pad bearing. ASLE Trans. 22(2), 113–124 (1979). https://doi.org/10.1080/05698197908982907

Chen, W.J.: Bearing dynamic coefficients of flexible-pad journal bearings. Tribol. Trans. 38(2), 253–260 (1995). https://doi.org/10.1080/10402009508983402

Kim, J., Palazzolo, A., Gadangi, R.: Dynamic characteristics of TEHD tilt pad journal bearing simulation including multiple mode pad flexibility model. J. Vib. Acoust. 117(1), 123–135 (1995). https://doi.org/10.1115/1.2873856

Allaire, P., Parsell, J., Barrett, L.: A pad perturbation method for the dynamic coefficients of tilting-pad journal bearings. Wear 72(1), 29–44 (1981). https://doi.org/10.1016/0043-1648(81)90281-7

Dang, P., Chatterton, S., Pennacchi, P.: The effect of the pivot stiffness on the performances of five-pad tilting pad bearings. Lubricants 61, 1–24 (2019). https://doi.org/10.3390/lubricants7070061

Jeung, S.-H., Suh, J., Yoon, H.: Performance of tilting pad journal bearings with the same sommerfeld number. Appl. Sci. 10(3529), 1–15 (1995). https://doi.org/10.3390/app10103529

Shi, Z., Jin, Y., Yuan, X.: Influence of pivot design on nonlinear dynamic analysis of vertical and horizontal rotors in tilting pad journal bearings. Tribol. Int. 140, 105859 (2019). https://doi.org/10.1016/j.triboint.2019.105859

Jin, Y., Chen, F., Zhang, F., Yuan, X.: Nonlinear dynamic performance of tilting-pad journal bearing with adjustable elastic pivot design. Tribol. Int. 136, 533–547 (2019). https://doi.org/10.1016/j.triboint.2019.04.022

Kirk, R.G., Reedy, S.W.: Evaluation of pivot stiffness for typical tilting-pad journal bearing designs. J. Vib. Acoust. Stress Reliab. Des. 110(2), 165–171 (1988). https://doi.org/10.1115/1.3269494

Mehdi, S.M., Jang, K.E., Kim, T.H.: Effects of pivot design on performance of tilting pad journal bearings. Tribol. Int. 119, 175–189 (2018). https://doi.org/10.1016/j.triboint.2017.08.025

Hagemann, T., Zemella, P., Pfau, B., Schwarze, H.: Experimental and theoretical investigations on transition of lubrication conditions for a five-pad tilting-pad journal bearing with eccentric pivot up to highest surface speeds. Tribol. Int. 142, 106008 (2020). https://doi.org/10.1016/j.triboint.2019.106008

Wang, Y., Gao, Y., Cui, Y., Liu, Z.: Establishment of approximate analytical model of oil film force for finite length tilting pad journal bearings. Int. J. Rotat. Mach. 2015, 1–11 (2015). https://doi.org/10.1155/2015/531209

Thomsen, K., Klit, P., Vølund, A.: Discontinuity effects in dynamically loaded tilting pad journal bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 225(7), 663–669 (2011). https://doi.org/10.1177/1350650111403037

Hori, Y.: Hydrodynamic Lubrication. Springer, Tokyo (2006)

Hensley, J.E., Childs, D.: Measurements versus predictions for rotordynamic characteristics of a flexure pivot-pad tilting pad bearing in an lbp condition at higher unit loads. In: Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air. Volume 5: Structures and Dynamics, Parts A and B, pp. 873–881 (2008). https://doi.org/10.1115/GT2008-50066

Chen, C.-H., Chen, C.-K.: The influence of fluid inertia on the operating characteristics of finite journal bearings. Wear 131(2), 229–240 (1989). https://doi.org/10.1016/0043-1648(89)90165-8

Someya, T.: Journal-Bearing Databook. Springer, Berlin (1989)

Pagano, S., Rocca, E., Russo, M., Russo, R.: Instability threshold of a rigid rotor-tilting pad journal bearings system. Int. J. Rotat. Mach. 3(3), 199–213 (1997). https://doi.org/10.1155/S1023621X97000195

Wolf, A., Swift, J.B., Swinney, H.L., Vastano, J.A.: Determining lyapunov exponents from a time series. Physica D 16(3), 285–317 (1985). https://doi.org/10.1016/0167-2789(85)90011-9

Acknowledgements

This work was supported by project SGS-2019-009, by European Regional Development Fund-Project “Research and Development of Intelligent Components of Advanced Technologies for the Pilsen Metropolitan Area (InteCom)” (No. CZ. 02.1.01/0.0/0.0/17 048/0007267) and by the Motivation system of the University of West Bohemia – Part Postdoc.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Solution strategy

A flowchart describing the solution strategy and the order of calculation steps inside the used solver is depicted in Fig. 21. The depicted flowchart shows only the inner part of the loop in the k-th iteration step. An output function is different for each type of each analysis and has the following form with respect to the notation used in (1):

-

1.

Static analysis—Static equilibrium points \(\mathbf{q} = \left[ \mathbf{q}_r, \mathbf{q}_p\right] ^T\) are determined if \(\mathbf{f}(\mathbf{q}) = \mathbf{0}\). The residuum function is defined as follows:

$$\begin{aligned} \mathbf{f}(\mathbf{q}) = \begin{bmatrix} \mathbf{f}_{g,r} + \mathbf{f}_{c,r} \\ \mathbf{f}_{g,r} + \mathbf{f}_{c,p} \end{bmatrix}. \end{aligned}$$(34) -

2.

Analysis of dynamics—The system of the second order differential equations (1) is transformed to the system of the first order differential equations using the mass identity

$$\begin{aligned} \begin{bmatrix} \mathbf{M}_r &{} \mathbf{0} \\ \mathbf{0} &{} \mathbf{M}_p \end{bmatrix} \begin{bmatrix} \dot{\mathbf{q}}_r \\ \dot{\mathbf{q}}_p \end{bmatrix} - \begin{bmatrix} \mathbf{M}_r &{} \mathbf{0} \\ \mathbf{0} &{} \mathbf{M}_p \end{bmatrix} \begin{bmatrix} \dot{\mathbf{q}}_r \\ \dot{\mathbf{q}}_p \end{bmatrix} = \begin{bmatrix} \mathbf{0} \\ \mathbf{0} \end{bmatrix}. \end{aligned}$$(35)The resulting system is solved for state-space vector \(\mathbf{x}(t) = \left[ \dot{\mathbf{q}}_r(t),\dot{\mathbf{q}}_p(t), \mathbf{q}_r(t),\mathbf{q}_p(t)\right] ^T\). The derivative of the state-space vector, which is evaluated in each iteration step of solver ode15s, can be written in the matrix form

$$\begin{aligned} \dot{\mathbf{x}}(t) = \begin{bmatrix} \begin{bmatrix} \mathbf{M}_r &{} \mathbf{0} \\ \mathbf{0} &{} \mathbf{M}_p \end{bmatrix}^{-1} \left( \begin{bmatrix} \mathbf{f}_{g,r} \\ \mathbf{f}_{g,p} \end{bmatrix} + \begin{bmatrix} \mathbf{f}_{un} \\ \mathbf{0} \end{bmatrix} + \begin{bmatrix} \mathbf{f}_{c,r} \\ \mathbf{f}_{c,p} \end{bmatrix} \right) \\ \dot{\mathbf{q}}_r \\ \dot{\mathbf{q}}_p \end{bmatrix}. \end{aligned}$$(36)

Determining the largest Lyapunov exponent from a time series

The largest Lyapunov exponent \(\lambda _{\mathrm {max}}\) is estimated using an algorithm proposed by Wolf et al. [32]. The exact implementation of the procedure follows:

-

1.

The response of the system is simulated sufficiently long. This condition is fulfilled if a simulated time series contains at least several hundred orbits, i.e. closed trajectories in the phase space.

-

2.

The transient response is removed from the simulated time series. The amount of the removed data vary between 0.4 and 3.9 s depending on the exact character of the time series. Although removing the transient response is not necessary, it accelerates the temporal convergence of \(\lambda _{\mathrm {max}}\) moderately.

-

3.

The cropped time series is decimated using a lowpass Chebyshev Type I infinite impulse response filter of order 8. The decimation factor is a positive integer selected so that the decimated time series has 18 samples per orbit.

-

4.

The decimated time series is analysed using Wolf’s algorithm [32] with the following parameters:

-

the dimension of the embedding phase space is 4,

-

the embedding delay is a third of an orbit,

-

the evolution time-step is a quarter of an orbit,

-

the minimum phase-space distance cut-off is defined by sequence \(\lbrace 0,\,0.02,\,0.04,\,\dots ,\,0.5 \rbrace \), which is given in per cents from the maximum-to-minimum difference of the decimated time series,

-

the maximum phase-space distance cut-off is defined by sequence \(\lbrace 8,\,8.25,\,8.5,\,\dots ,\,15 \rbrace \), which is given in per cents from the maximum-to-minimum difference of the decimated time series.

-

-

5.

All combinations of the parameters yield 754 running estimates of \(\lambda _{\mathrm {max}}\). The last 100 samples are taken from each running estimate to an array accommodating 75400 estimates of \(\lambda _{\mathrm {max}}\) for each decimated time series. The array is further used to calculate the median and the mean difference from the median.

Rights and permissions

About this article

Cite this article

Rendl, J., Dyk, Š. & Smolík, L. Nonlinear dynamic analysis of a tilting pad journal bearing subjected to pad fluttering. Nonlinear Dyn 105, 2133–2156 (2021). https://doi.org/10.1007/s11071-021-06748-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-021-06748-x