Abstract

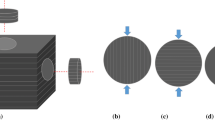

The anisotropic deformation of oil shale at different temperatures should be given particular attention considering that thermal deformation affects borehole stability, oil and gas permeation channel formation and surface subsidence during the pyrolysis of oil shale. The deformation of oil shale parallel and perpendicular to the bedding directions under different triaxial stresses was studied from room temperature to 600 °C. Evolutions in mineral compositions and thermal fracturing were studied by X-ray diffractometry and computer tomography, respectively. The main results are as follows. (1) Under 2.5 and 5 MPa axial stresses, the thermal deformation perpendicular to the bedding direction shows compressive deformation with increasing temperature, and the strain rate increases sharply at 200 °C, 350 °C and 400 °C. When the axial stress is 10 MPa, the deformation rate increases sharply when the temperature increases to 100 °C, and then, the compression deformation increases almost linearly. (2) Under 2.5 and 5 MPa axial stresses, the thermal deformation parallel to the bedding tends to be expansion–compression–expansion–recompression with increasing temperature. When the axial stress increases to 10 MPa, the overall deformation of the material will be compression deformation, and no expansion deformation will occur with the increase in temperature. (3) The deformation characteristics under the coupled action of temperature and stress are less related to mineral changes but more related to fracture evolution characteristics. (4) Thermal stress has a great influence on the thermal deformation of oil shale perpendicular to the bedding directions but little effect on the thermal deformation parallel to the bedding directions.

Similar content being viewed by others

References

Bai, J., Li, X., Geng, S., Wang, Q., & Liu, B. (2014). Investigation on isothermal drying mechanism of Yaojie Oilshale. Chemical Industry and Engineering Progress, 33(01), 75–79+116. (In Chinese).

Bai, F., Sun, Y., Liu, Y., & Guo, M. (2017). Evaluation of the porous structure of Huadian oil shale during pyrolysis using multiple approaches. Fuel, 187, 1–8.

Brandt, A. R. (2008). Converting oil shale to liquid fuels: energy inputs and greenhouse gas emissions of the Shell in situ conversion process. Environmental Science and Technology, 42(19), 7489–7495.

Brantut, N., Heap, M. J., Meredith, P. G., & Baud, P. (2013). Time-dependent cracking and brittle creep in crustal rocks: a review. Journal of Structural Geology, 52, 17–43.

Burnham, A. K. (2018). Thermomechanical properties of the Garden Gulch Member of the Green River Formation. Fuel, 219, 477–491.

Burnham, A., Switzer, L., Day, R. L., McConaghy, J., Hradisky, M., Coats, D., et al. (2012). Initial results from the AMSO RD&D pilot test program. In Proceedings of the 32nd oil shale symposium (pp. 15–17). Golden, CO: Colorado School of Mines.

Crawford, P., Biglarbigi, K., Dammer, A., & Knaus, E. (2008). Advances in world oil-shale production technologies. In SPE annual technical conference and exhibition, Denver (pp. 21–24).

Ding, Q. L., Ju, F., Song, S. B., Yu, B. Y., & Ma, D. (2016). An experimental study of fractured sandstone permeability after high-temperature treatment under different confining pressures. Journal of Natural Gas Science and Engineering, 34, 55–63.

Feng, Z., Zhao, Y., & Wan, Z. (2017). Effect of temperature on deformation of triaxially stressed anthracite. Rock Mechanics and Rock Engineering, 50(4), 1073–1078.

Guo, X., Zou, G., Wang, Y., Wang, Y., & Gao, T. (2017). Investigation of the temperature effect on rock permeability sensitivity. Journal of Petroleum Science and Engineering, 156, 616–622.

Heuze, F. E. (1983). High-temperature mechanical, physical and thermal properties of granitic rocks—a review. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 20(1), 3–10.

Kang, Z. (2008a). The pyrolysis characteristics and in situ hot drive simulation research that exploit oil-gas of oil shale. Taiyuan University of Technology (in Chinese).

Kang, Z. (2008b). Physical principle and numerical analysis of oil shale development using in situ conversion process technology. Acta Petrolei Sinica, 29(4), 592–595.

Lin, W. (2002). Permanent strain of thermal expansion and thermally induced microcracking in Inada granite. Journal of Geophysical Research: Solid Earth, 107(B10), ECV-3.

Liu, S., Zhang, S., Chen, F., Wang, C., & Liu, M. (2014). Variation of coal permeability under dehydrating and heating: a case study of ulanqab lignite for underground coal gasification. Energy & Fuels, 28(11), 6869–6876.

Liu, X., Zhang, C., Yuan, S., Fityus, S., Sloan, S. W., & Buzzi, O. (2016). Effect of high temperature on mineralogy, microstructure, shear stiffness and tensile strength of two Australian mudstones. Rock Mechanics and Rock Engineering, 49(9), 3513–3524.

Ma, Y., Pan, Z., Zhong, N., Connell, L. D., Down, D. I., Lin, W., et al. (2016). Experimental study of anisotropic gas permeability and its relationship with fracture structure of Longmaxi Shales, Sichuan Basin, China. Fuel, 180, 106–115.

Masri, M., Sibai, M., Shao, J. F., & Mainguy, M. (2014). Experimental investigation of the effect of temperature on the mechanical behavior of Tournemire shale. International Journal of Rock Mechanics and Mining Sciences, 70, 185–191.

Niu, S., Zhao, Y., & Hu, Y. (2014). Experimental investigation of the temperature and pore pressure effect on permeability of lignite under the in situ condition. Transport in Porous Media, 101(1), 137–148.

Saif, T., Lin, Q., Bijeljic, B., & Blunt, M. J. (2017a). Microstructural imaging and characterization of oil shale before and after pyrolysis. Fuel, 197, 562–574.

Saif, T., Lin, Q., Butcher, A. R., Bijeljic, B., & Blunt, M. J. (2017b). Multi-scale multi-dimensional microstructure imaging of oil shale pyrolysis using X-ray micro-tomography, automated ultra-high resolution SEM, MAPS Mineralogy and FIB-SEM. Applied Energy, 202, 628–647.

Sone, H., & Zoback, M. D. (2013). Mechanical properties of shale-gas reservoir rocks—part 2: Ductile creep, brittle strength, and their relation to the elastic modulus. Geophysics, 78(5), D393–D402.

Suarez-Rivera, R., Marino, S., & Ghassemi, A. (2010). Sustaining fracture area and conductivity of gas shale reservoirs for enhancing long-term production and recovery. In: AGU fall meeting abstracts.

Sun, Y., Bai, F., Liu, B., Liu, Y., Guo, M., Guo, W., et al. (2014). Characterization of the oil shale products derived via topochemical reaction method. Fuel, 115, 338–346.

Tiwari, P., Deo, M., Lin, C. L., & Miller, J. D. (2013). Characterization of oil shale pore structure before and after pyrolysis by using X-ray micro ct. Fuel, 107, 547–554.

Wang, J., Feng, L., Steve, M., Tang, X., Gail, T. E., & Mikael, H. (2015). China’s unconventional oil: A review of its resources and outlook for long-term production. Energy, 82, 31–42.

Wang, G., Yang, D., Zhao, Y., Kang, Z., Zhao, J., & Huang, X. (2019). Experimental investigation on anisotropic permeability and its relationship with anisotropic thermal cracking of oil shale under high temperature and triaxial stress. Applied Thermal Engineering, 146, 718–725.

Xiao, Y., Lu, J. H., Wang, C. P., & Deng, J. (2016). Experimental study of high-temperature fracture propagation in anthracite and destruction of mudstone from coalfield using high-resolution microfocus X-ray computed tomography. Rock Mechanics and Rock Engineering, 49(9), 3723–3734.

Yu, Y. (2015). Research on fracture and damage behaviour of oil shale under thermal-mechanical coupling field. Taiyuan University of Technology (in Chinese).

Zhang, L., Mao, X., Li, M., & Liu, R. (2018). Experimental study of thermal expansion characteristics of coaly mudstone at high temperatures. Geotechnical and Geological Engineering, 36(1), 521–529.

Zhou, H., Liu, H., Hu, D., Yang, F., Lu, J., & Zhang, F. (2016). Anisotropies in mechanical behaviour, thermal expansion and P-wave velocity of sandstone with bedding planes. Rock Mechanics and Rock Engineering, 49(11), 4497–4504.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. U1261102, 11772213), the National Natural Science Foundation for Young Scientists of China (Grant No. 51704206) and National Key Research and Development Project of China (Grant No. 2019YFA0705500).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, D., Wang, G., Kang, Z. et al. Experimental Investigation of Anisotropic Thermal Deformation of Oil Shale Under High Temperature and Triaxial Stress Based on Mineral and Micro-fracture Characteristics. Nat Resour Res 29, 3987–4002 (2020). https://doi.org/10.1007/s11053-020-09663-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-020-09663-x