Abstract

A bifunctional hybrid nanomaterial, which can show magnetic and luminescent properties, was obtained. A magnetic phase was synthesized as a core/shell type composite. Nanocrystalline magnetite, Fe3O4 was used as the core and was encapsulated in a silica shell. The luminescent phase was GdPO4 doped with Eu3+ ions, as the emitter. The investigated materials were synthesized using a coprecipitation method. Encapsulated Fe3O4 was “trapped” in a nano-scaffold composed of GdPO4 crystalline nanoneedles. When an external magnetic field was applied, this hybrid composite was attracted in one direction. Also, the luminescent phase can move simultaneously with magnetite due to a “trapping” effect. The structure and morphology of the obtained nanocomposites were examined with the use of transmission electron microscopy and X-ray powder diffraction. Spectroscopic properties of the Eu3+-doped nanomaterials were studied by measuring their excitation and emission spectra as well as their luminescence decay times.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nanocomposite structures with suitable dual or multifunctional properties have the potential to be useful in applications in areas such as biology and medicine (biomarkers, drug delivery, cells labeling, sensitive to magnetic field nanoparticles for the photodynamic therapy) and also in optoelectronics and lightening (Mi et al. 2010; Sun et al. 2010; Hu et al. 2011). Many research groups are currently focussed on the synthesis as well as the exploration of the properties of core/shell type nanostructures and other, similar composites like hybrid nanomaterials (Binnemans 2009; Dosev et al. 2007; Yu et al. 2006; Hu et al. 2010). Core/shell structures are usually composed of homogeneous nanosized particles as cores, which are wrapped by inert or active mono- or multishells. Examples of core/shell structures are metallic particles, which can be covered by silica shell (Liz-Marzán et al. 1996) or semiconductor nanoparticles like CdSe@SiO2 (Correa-Duarte et al. 1998). The composition of the cores and shells are not restricted, but the characteristics of shells have the greatest influence on the properties of the final product. Other factors which can potentially influence core/shell type compound properties are: the ratio of the number of particles in the core to the number of particles in the shell, particles size, homogeneity and distribution of their size, crystallinity and morphology, dopant concentrations, and impurities and defects in the structures.

Cores, which can show magnetic behavior, are composed of the oxides Fe3O4, Co3O4, or metal Ni, FePt nanoparticles (Runowski et al. 2011; Park et al. 2010; López Pérez et al. 1997; Son et al. 2007; Chen et al. 2011; Yano et al. 2009). Synthesis of core/shell structures can avoid the oxidation of cores (Sobal et al. 2002). Also, inert SiO2 nanoparticles are often used as cores (Yu et al. 2006). Other examples are semiconductors like ZnO and CdSe (Wang et al. 2010a; Darbandi et al. 2005) or inorganic, lanthanide-doped compounds like fluorides e.g., CeF3:Tb3+ and NaYF4:Yb3+,Er3+ (Runowski et al. 2011; Hu et al. 2011). The shell can also show fluorescent properties (organic or inorganic phosphors), e.g., rhodamine, LaF3:Ce3+,Tb3+, or CdTe (Sun et al. 2010; Chang et al. 2008; He et al. 2009). Functionalization of the shell can be accomplished by covering the surface of the particle with compounds which can behave as coordination ligands having appropriate groups, e.g., –SH and –NH2. Hydrophobic ligands on the surface of the as-prepared nanoparticles may be replaced by ligand-exchange reactions; employing one of a wide variety of currently used organic compounds like polyethylene glycol and its derivatives (PEG), polyacrylic acid (PPA) (Shenoy et al. 2006; Wang et al. 2010b), or polyethylenimine (PEI) (Wang et al. 2007). Alternatively, native capping ligands can be modified by oxidation or more advanced ligand engineering like polymerization or by reactions with additional compounds.

These hybrid structures may also be used in water purification from heavy metals, taking advantage of the large affinity of these composite particles, with large surface ratios, to the cations of metals, e.g., Pb2+, Cd2+, and Hg2+ (Wang et al. 2010c). This large affinity is due to the large surface area of nanostructures and to binding of the cations via –NH2 groups or via physical forces. When the above-mentioned structures are magnetic, an external magnetic field (like a strong magnet) can be used for very easy and quick purification of the structures. Another example of the potential application for nanohybrids, with magnetic cores, is in the area of condensing and removing bacteria and other microorganisms from water using the properties of appropriately biomodified shells. Core/shell structures and other advanced nanocomposites may also be used as biomarkers and contrast agents in imaging techniques like MRI (magnetic resonance imaging), which use paramagnetic or superparamagnetic compounds (usually based on gadolinium or iron oxide compounds) (Zhu et al. 2011).

When luminescent particles (organic compounds, polymers, quantum dots, rare earth-based UV-excited or upconversion phosphors) are incorporated into the shells, which could bind with microorganisms (binding with antibodies, antigens, polypeptides, etc.) or tumor tissue (Nyk et al. 2008; Selvan et al. 2009), the biocomplex can be localized by irradiation with UV or NIR light. After that due to luminescent and magnetic (optionally) properties, the biocomplex can be cured or removed. Also, drug delivery could be enhanced using magnetic nanoparticles (Yang et al. 2009).

When luminescent particles (organic compounds, polymers, quantum dots, rare earth-based UV-excited or upconversion phosphors) are incorporated into the shells, which could bind with microorganisms (binding with antibodies, antigens, polypeptides, etc.) or tumor tissue (Nyk et al. 2008; Selvan et al. 2009), the biocomplex can be localized by irradiation with UV or NIR light. Also, drug delivery could be enhanced using magnetic nanoparticles (Yang et al. 2009).

Experimental

Synthesis of magnetic core (Fe3O4)

The starting materials, 5.4 g FeCl3·6H2O (POCh S.A., pure p.a.) and 2.78 g FeSO4·7H2O (POCh S.A., pure p.a.) were mixed together in the molar ratio 2:1 and dissolved in distilled water. Subsequently, 0.5 g hydrazine sulfate (N2H4·H2O, Sigma-Aldrich, reagent grade) was added to the water solution as an antioxiding agent. The obtained solution was transferred to a round-bottom flask and filled with water up to 400 mL. Afterward an ammonia solution (20 mL of 10 % solution, POCh S.A., pure p.a.) was injected into the previous solution. Immediately, a black precipitate of Fe3O4 nanoparticles was obtained via the modified Massart method (Massart 1981). The reaction was continued for approximately 1 h. Intense stirring was maintained during the whole reaction process. The temperature of the solution was set to 50 °C. When the reaction process was finished, the solution was ultrasonicated for approximately 1 h, to produce well-dispersed, small, and homogeneous nanoparticles of magnetite. The obtained nanoparticles of Fe3O4 were separated using a strong magnet and washed several times with water.

Synthesis of core/shell Fe3O4/SiO2

Covering the obtained Fe3O4 nanoparticles by a silica shell was accomplished using a modified Stöber method (Stöber et al. 1968). 0.03 g of the previously synthesized magnetite was dispersed in 50 mL of water and ultrasonicated for 30 min. The colloidal suspension of magnetite was then transferred to a beaker and filled with 25 mL of ethylene glycol (POCh S.A., pure p.a.) and 25 mL of glycerin (POCh S.A., pure p.a.). To the well-mixed homogeneous solution, 2.5 mL of tetraethyl orthosilicate (TEOS, Sigma-Aldrich, reagent grade, 98 %) was added. After that, 25 mL of the 10 % ammonia solution was added to start the hydrolysis process (the addition time was approximately 20 min.). After addition of ammonia, the reaction was continued for 50 min. The solution was intensely stirred and heated to 50 °C for the whole reaction process. The obtained core/shell nanoparticles of Fe3O4/SiO2 were separated with a strong magnet and washed several times with water and ethanol.

Synthesis of the magnetic-luminescent nanocomposite based on Fe3O4/SiO2 and GdPO4:Eu3+ nanoneedles

The entire amount of the previously obtained Fe3O4/SiO2 nanoparticles was dispersed in a mixture of 50 mL water, 25 mL ethylene glycol, and 25 mL glycerin. Ammonium phosphate monobasic ((NH4)H2PO4, Sigma-Aldrich, ReagentPlus®, ≥98.5 %) was dissolved in the prepared solution and stirred together for 15 min. Subsequently the rare-earth nitrates, Gd(NO3)3 and Eu(NO3)3, were prepared by dissolving the oxides Gd2O3 and Eu2O3 (stanford materials, 99.99 %) in HNO3 (POCh S.A., ultra-pure). Obtained nitrates were dissolved in the system composed of water, ethylene glycol, and glycerin (in the ratio mentioned above). All the reactants were used in stoichiometric ratios, assuming the synthesis of 1 g of the product, and Eu3+ molar concentrations of 7.5 or 20 %. The obtained mixture was dropped into a colloidal solution containing ammonium phosphate and Fe3O4/SiO2 nanoparticles within 15 min. When the addition was finished, the reaction was continued for 20 min; for better incorporation of the precipitate on the surface of nanoparticles. The solution was intensely stirred and heated to 50 °C during the whole reaction process. The obtained nanoparticles of the magnetic product were separated using a strong magnet and washed several times with water and ethanol.

Apparatus

XRD patterns were obtained with a Bruker AXS D8 Advance diffractometer in Bragg–Brentano geometry, with Cu Kα1 radiation in the 2θ range from 6° to 60°. The joint committee on powder diffraction standards (JCPDS) database was used for the phase identification. The Scherrer equation was used for calculating average sizes of the crystallites (Scherrer 1918)]:

where D is the average grain size, λ is the X-ray wavelength, the factor 0.9 is characteristic for spherical objects, θ is the diffraction angle, and β is the full-width at half-maximum of an observed peak. TEM images were measured with a JEM 1200 EXII, JOEL transmission electron microscope, using an accelerating voltage of 80 kV.

An Hitachi F-7000 fluorescence spectrophotometer with a 150 W xenon lamp was used for the determination of the luminescence properties (excitation, emission, and lifetimes) of the samples at room temperature. The obtained spectra were corrected for instrumental response.

The presence of magnetic properties of the final product was confirmed with a strong applied external magnetic field (rare-earth magnet).

Results and discussion

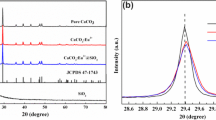

A powder XRD analysis of the Fe3O4 nanoparticles (Fig. 1) confirmed the structure of magnetite. The estimated value of the average size of the magnetite particles from XRD, using the Scherrer equation, was approximately 17 ± 3 nm. The estimated value is in good correlation with the TEM image (Fig. 3).

The XRD patterns of the obtained hybrid nanomaterials are shown in Fig. 2. They are in good agreement with diffraction patterns from the database for the hydrated, hexagonal GdPO4·1.5H2O (JCPDS card no. 21-0337). Small changes in intensities and positions of some peaks were caused by the difference between the Gd3+ ion radius and the Eu3+ ion radius. Some reflection peaks originated from magnetite are almost invisible, due to the low concentration of Fe3O4 in total mass of the sample. There are no peaks from SiO2 because of the amorphous structure of the silica shell.

Figure 3 presents the TEM image of the core/shell Fe3O4/SiO2 nanostructure. In the picture, the formation of the core/shell type compound is clearly seen. The darker core corresponds to the magnetite, and the lighter shell is composed of the amorphous silica. The obtained core/shell type product showed magnetic behavior, which could be confirmed when an external magnetic field was applied. The size distribution of the nanoparticles was calculated using TEM data (Fig. 3). The relatively uniform size distribution of the grains is quite encouraging in our composite product.

Figure 4 presents the TEM image of the composite, magnetic-luminescent nanomaterial based on Fe3O4/SiO2 and GdPO4:Eu3+ nanoneedles. The calculated dimensions (from the TEM picture) of these nanoneedles are 40–250 nm long and 3–15 nm wide. This complex nanocomposite material showed simultaneously magnetic and luminescent properties.

Excitation and emission spectra are shown in Figs. 5, 6. Two concentrations of the dopant, Eu3+ ions, were used as emission activators. The prepared compound can be excited by UV radiation at the optimal wavelength of λex = 245 nm. This wavelength corresponds to the maximum of the wide band, which is connected with charge transfer between the O2− and Eu3+ ions. Less intense peaks around 270 and 390 nm are due to the energy transfer from Gd3+ to Eu3+ and to the f–f transitions in the Eu3+ ions, respectively.

When the concentration of Eu3+ was increased from 7.5 to 20 %, a more intense emission could be observed. Usually, the optimal concentration of a dopant-like Eu3+ in phosphors is in the range of 5–10 %. When the concentration is increased, cross-relaxation is observed, and the excited Eu3+ ions are quenched (Weber 1968). The observed small quenching in the higher doped sample could be connected with the abnormal environment of the Eu3+ ions. The shape of the GdPO4 nanoparticles (nanoneedles) results in a larger surface to volume ratio, compared to spherical objects. In such a case, the Eu3+ ions are mostly on the surface. Therefore, concentration quenching is less efficient, and the optimal concentration is shifted.

The observed emission was intensely red, and four transition peaks characteristic for the Eu3+ emission spectrum were observed. The ratio of 5D0 → 7F1 to 5D0 → 7F2 transitions is characteristic of the high-symmetry environment of the Eu3+ ions (Görller-Warland and Binnemans 1998). Two low-energy transitions 5D0 → 7F3 and 5D0 → 7F4 were also observed.

Figure 7 presents the luminescent and magnetic properties of the Fe3O4/SiO2–GdPO4:Eu3+ 20 % nanoproduct dispersed in water. It is clearly seen that, after magnet capture, all the nanoparticles were attracted to the cuvette wall. When the UV light was on, the characteristic red luminescence of the Eu3+ ion was observed. This behavior confirms the formation of the hybrid, bifunctional nanophosphor.

Emission decay curves of the prepared materials are presented in Fig. 8. The obtained curves were both fitted to biexponential decays with good correlation coefficients. The two lifetimes originate from two different Eu3+ ions, occupying sites inside the nanocrystals and on their surface, where the ions are surrounded by different environments. Their values are typical for Eu3+ in inorganic hosts (Liu et al. 2007; Wiglusz et al. 2010), and both are shortened in samples with higher concentrations of Eu3+. The shorter lifetimes are due to the concentration quenching.

Conclusions

A bifunctional, magnetic-luminescent, nanomaterial was obtained, using a simple, coprecipitation method. The described nanocomposite is sensitive to external magnetic fields. The obtained product was attracted to magnets both in the solid state (as a dry powder) and in water dispersed state as a colloid. The UV lamp with a maximum emission at 254 nm was used to excite this composite, and an intense red luminescence was visible. Such a luminescence was also observable in an aqueous system, which is not common for Eu3+ containing compounds. These ions are usually quenched in aqueous medium due to vibronic coupling with O–H oscillators (Lis 2002; Klonkowski et al. 2003). We report that quenching was minimal in the synthesized nanocomposite. This property can be of interest in potential applications. However, the mechanism of this phenomena and the influence of the environment should be examined and discussed in further research.

The properties of the discussed nanocomposite were examined using photophysical methods. This nanohybrid product showed simultaneously magnetic and luminescent properties and can be used in many fields of science (e.g., nanochemistry, biochemistry, pharmacy, medicine, and industry). These modern biochemical and physicochemical approaches based on nanotechnology could be enhanced due to the novel properties of these nanomaterials.

References

Binnemans K (2009) Lanthanide-based luminescent hybrid materials. Chem Rev 109:4283–4374. doi:10.1021/cr8003983

Chang Q, Zhu L, Yu C, Tang H (2008) Synthesis and properties of magnetic and luminescent Fe3O4/SiO2/Dye/SiO2 nanoparticles. J Lumin 128:1890–1895. doi:10.1016/j.jlumin.2008.05.014

Chen G, Desinan S, Nechache R, Rosei R, Rosei F, Ma D (2011) Bifunctional catalytic/magnetic Ni@Ru core–shell nanoparticles. Chem Commun 47:6308–6310. doi:10.1039/C1CC10619H

Correa-Duarte MA, Giersig M, Liz-Marzán LM (1998) Stabilization of CdS semiconductor nanoparticles against photodegradation by a silica coating procedure. Chem Phys Lett 286:497–501. doi:10.1016/S0009-2614(98)00012-8

Darbandi M, Thomann R, Nann T (2005) Single quantum dots in silica spheres by microemulsion synthesis. Chem Mater 17:5720–5725. doi:10.1021/cm051467h

Dosev D, Nichkova M, Dumas RK, Gee SJ, Hammock BD, Liu K, Kennedy IM (2007) Magnetic/luminescent core/shell particles synthesized by spray pyrolysis and their application in immunoassays with internal standard. Nanotechnology 18:55102–55118. doi:10.1088/0957-4484/18/5/055102

Görller-Warland C, Binnemans K (1998) Handbook on the physics and chemistry of rare earths. Elsevier 25:101–264

He H, Xie M, Ding Y, Yu X (2009) Synthesis of Fe3O4@LaF3:Ce, Tb nanocomposites with bright fluorescence and strong magnetism. Appl Surf Sci 255:4623–4626. doi:10.1016/j.apsusc.2008.11.086

Hu H, Wang Z, Pan L (2010) Synthesis of monodisperse Fe3O4@silica core–shell microspheres and their application for removal of heavy metal ions from water. J Alloys Compd 492:656–661. doi:10.1016/j.jallcom.2009.11.204

Hu D, Chen M, Gao Y, Li F, Wu L (2011) A facile method to synthesize superparamagnetic and up-conversion luminescent NaYF4:Yb, Er/Tm@SiO2@Fe3O4 nanocomposite particles and their bioapplication. J Mater Chem 21:11276–11282. doi:10.1039/C1JM11172H

Klonkowski AM, Lis S, Pietraszkiewicz M, Hnatejko Z, Czarnobaj K, Elbanowski M (2003) Luminescence properties of materials with Eu(III) complexes: role of ligand, coligand, anion, and matrix. Chem Mater 15:656–663. doi:10.1021/cm0202557

Lis S (2002) Luminescence spectroscopy of lanthanide(III) ions in solution. J Alloys Compd 341:45–50. doi:10.1016/S0925-8388(02)00055-5

Liu L, Ma E, Li R, Liu G, Chen X (2007) Effects of phonon confinement on the luminescence dynamics of Eu3+ in Gd2O3 nanotubes. Nanotechnology 18:015403. doi:10.1088/0957-4484/18/1/015403

Liz-Marzán LM, Giersig M, Mulvaney P (1996) Synthesis of nanosized gold–silica core–shell particles. Langmuir 12:4329–4335. doi:10.1021/la9601871

López Pérez JA, López Quintela MA, Mira J, Rivas J, Charles SW (1997) Advances in the preparation of magnetic nanoparticles by the microemulsion method. J Phys Chem B 101:8045–8047. doi:10.1021/jp972046t

Massart R (1981) Preparation of aqueous magnetic liquids in alkaline and acidic media. IEEE Trans Magn 17:1247–1248. doi:10.1109/TMAG.1981.1061188

Mi C, Zhang J, Gao H, Wu X, Wang M, Wu Y, Di Y, Xu Z, Mao C, Xu S (2010) Multifunctional nanocomposites of superparamagnetic (Fe3O4) and NIR-responsive rare earth-doped up-conversion fluorescent (NaYF4:Yb,Er) nanoparticles and their applications in biolabeling and fluorescent imaging of cancer cells. Nanoscale 2:1141–1148. doi:10.1039/C0NR00102C

Nyk M, Kumar R, Ohulchanskyy TY, Bergey EJ, Prasad PN (2008) High contrast in vitro and in vivo photoluminescence bioimaging using near infrared to near infrared up-conversion in Tm3+ and Yb3+ doped fluoride nanophosphors. Nano Lett 8:3834–3838. doi:10.1021/nl802223f

Park JN, Zhang P, Hu YS, McFarland EW (2010) Synthesis and characterization of sintering-resistant silica-encapsulated Fe3O4 magnetic nanoparticles active for oxidation and chemical looping combustion. Nanotechnology 21:225708–225716. doi:10.1088/0957-4484/21/22/225708

Runowski M, Grzyb T, Lis S (2011) Bifunctional luminescent and magnetic core/shell type nanostructures Fe3O4@CeF3:Tb3+/SiO2. J Rare Earths 29:1117–1122. doi:10.1016/S1002-0721(10)60609-6

Scherrer P (1918) Bestimmung der Grösse und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachr Ges Wiss Göttingen 26:98–100

Selvan ST, Tan TTY, Yi DK, Jana NR (2009) Functional and multifunctional nanoparticles for bioimaging and biosensing. Langmuir 26:11631–11641. doi:10.1021/la903512m

Shenoy D, Fu W, Li J, Crasto C, Jones G, DiMarzio C, Sridhar S, Amiji M (2006) Surface functionalization of gold nanoparticles using hetero-bifunctional poly (ethylene glycol) spacer for intracellular tracking and delivery. Int J Nanomed 1:51–58. doi:10.2147/nano.2006.1.1.51

Sobal NS, Hilgendorff M, Möhwald H, Giersig M, Spasova M, Radetic T, Farle M (2002) Synthesis and structure of colloidal bimetallic nanocrystals: the non-alloying system Ag/Co. Nano Lett 2:621–624. doi:10.1021/nl025533f

Son A, Dosev D, Nichkova M, Ma Z, Kennedy IM, Scow KM, Hristova KR (2007) Quantitative DNA hybridization in solution using magnetic/luminescent core–shell nanoparticles. Anal Biochem 370:186–194. doi:10.1016/j.ab.2007.08.001

Stöber W, Fink A, Bohn E (1968) Controlled growth of monodisperse silica spheres in the micron size range. J Colloid Interface Sci 26:62–69. doi:10.1016/0021-9797(68)90272-5

Sun P, Zhang H, Liu C, Fang J, Wang M, Chen J, Zhang J, Mao C, Xu S (2010) Preparation and characterization of Fe3O4/CdTe magnetic/fluorescent nanocomposites and their applications in immuno-labeling and fluorescent imaging of cancer cells. Langmuir 26:1278–1284. doi:10.1021/la9024553

Wang F, Fan X, Wang M, Zhang Y (2007) Multicolour PEI/NaGdF4:Ce3+, Ln3+ nanocrystals by single-wavelength excitation. Nanotechnology 18:25701–25706. doi:10.1088/0957-4484/18/2/025701

Wang J, Tsuzuki T, Sun L, Wang X (2010a) Reverse microemulsion-mediated synthesis of SiO(2)-coated ZnO composite nanoparticles: multiple cores with tunable shell thickness. ACS Appl Mater Interfaces 2:957–960. doi:10.1021/am100051z

Wang F, Banerjee D, Liu Y, Chen X, Liu X (2010b) Upconversion nanoparticles in biological labeling, imaging, and therapy. Analyst 135:1839–1854. doi:10.1039/C0AN00144A

Wang J, Zheng S, Shao Y, Liu J, Xu Z, Zhu D (2010c) Amino-functionalized Fe3O4@SiO2 core–shell magnetic nanomaterial as a novel adsorbent for aqueous heavy metals removal. J Colloid Interface Sci 349:293–299. doi:10.1016/j.jcis.2010.05.010

Weber M (1968) Radiative and multiphonon relaxation of rare-earth ions in Y2O3. Phys Rev 171:283–291. doi:10.1103/PhysRev.171.283

Wiglusz RJ, Grzyb T, Lis S, Strek W (2010) Hydrothermal preparation and photoluminescent properties of MgAl2O4:Eu3+ spinel nanocrystals. J Lumin 130:434–441. doi:10.1016/j.jlumin.2009.10.009

Yang P, Quan Z, Hou Z, Li C, Kang X, Cheng Z, Lin J (2009) A magnetic, luminescent and mesoporous core–shell structured composite material as drug carrier. Biomaterials 30:4786–4795. doi:10.1016/j.biomaterials.2009.05.038

Yano K, Nandwana V, Chaubey GS, Poudyal N, Kang S, Arami H, Griffis J, Liu JP (2009) Synthesis and characterization of magnetic FePt/Au core/shell nanoparticles. J Phys Chem C 113:13088–13091. doi:10.1021/jp901985u

Yu M, Wang H, Lin CK, Li GZ, Lin J (2006) Sol–gel synthesis and photoluminescence properties of spherical SiO2@LaPO4:Ce3+/Tb3+ particles with a core–shell structure. Nanotechnology 17:3245–3252. doi:10.1088/0957-4484/17/13/028

Zhu R, Jiang W, Pu Y, Luo K, Wu Y, He B, Gu Z (2011) Functionalization of magnetic nanoparticles with peptide dendrimers. J Mater Chem 21:5464–5474. doi:10.1039/c0jm02752a

Acknowledgments

T. G. gratefully acknowledges the financial support in the form of the VENTURES project operated by the Foundation for Polish Science and financed by the EU European Regional Development Fund, Ventures/2009-4/2.

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Runowski, M., Grzyb, T. & Lis, S. Magnetic and luminescent hybrid nanomaterial based on Fe3O4 nanocrystals and GdPO4:Eu3+ nanoneedles. J Nanopart Res 14, 1188 (2012). https://doi.org/10.1007/s11051-012-1188-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-012-1188-7