Abstract

Creep in archaeological oak samples and planks from the Vasa ship impregnated with polyethylene glycol (PEG) has been studied in museum-like climate. Creep studies of duration up to three years have been performed in nearly constant relative humidity and temperature of the controlled museum climate. Cubic samples were subjected to compressive creep tests in all orthotropic directions. Additionally, the creep behaviour of planks with and without PEG and of recent oak was tested in four-point bending. The experimental results have been summarised and also compared with reference results from recent oak wood. The effect of variable ambient conditions on creep and mass changes is discussed. The experimental results of creep in the longitudinal direction showed deformations even for the low stresses. There is relatively much more scatter in creep behaviour, and not all samples showed linear viscoelastic response. The creep in radial and tangential directions of the cubes and the plank samples showed a strong dependency on the ambient conditions. Some samples showed expansion for decreasing moisture content, possibly caused by the thermal expansion of the PEG component. For the planks, increasing creep deformation was observed induced by changing ambient conditions. Such behaviour may be related to e.g. oscillations in ambient conditions and presence of PEG in the wood cell wall and cell lumen. The behaviour of PEG archaeological wood depends on the level of deterioration that occurred over centuries. However, although the findings presented here apply to this specific case, they provide a unique view on such wood.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Wood as a material has played and continues to play a significant role for humanity. It has been used since prehistoric times as a preferred structural material for buildings and tools and has by no means lost its popularity today. The bulk of wood is nowadays used for paper, packaging, furniture and renewable building materials. Historical wood artifacts take a significant place in the museum expositions all around the world. Wood is a degradable biopolymer with a porous and cellular structure. It is significantly affected by the environment to which it is exposed. The hygroscopic nature of wood causes moisture to migrate into its tissue to achieve equilibrium, which results in dimensional changes, mass fluctuations and changes in mechanical behaviour in a varying climate. In addition to the effects of moisture and temperature, chemical and biological degradation make preservation of wooden artifacts an important and challenging task for museums. For wood artifacts, which are in danger of deformation and fracture damage due to changes in moisture content, special care has to be taken.

Once taken out from a wet environment, water-logged archaeological wood inevitably shrinks due to drying, which often results in warping and cracking. Impregnation with polyethylene glycol (PEG) is commonly used in conservation to dimensionally stabilise wet archaeological wood due to its good anti-shrinkage properties (Morén and Centerwall 1961; Norimoto et al. 1992). This treatment allows the material to be conserved in its initial swollen state as the free water molecules are replaced by stationary PEG molecules. As compared with the non-impregnated wood material, the other main effects of PEG impregnation are increased mass density, increased hygroscopicity of the dried material and material softening since PEG acts as a plasticiser (Hoffmann et al. 2013). Large-sized archaeological artifacts such as wooden ships, for example, the Bremer Cog in Bremerhaven, the Mary Rose in Portsmouth and the Vasa in Stockholm (Hoffmann 1988; Jones et al. 1986; Cederlund and Hocker 2006), which underwent centuries buried at the bottom of sea are usually resting on supporting structures, typically cradles similar as those used in dry docks and for winter storage of yachts. Consideration of the effects of PEG impregnation is crucial for the preservation of these sensitive objects of cultural heritage.

Factors such as museum environment and design of the support structure are essential for the preservation process. In the long run, wooden structures have an apparent tendency to deform due to their mass and other factors, like environment or external loads. Since the loads do not fluctuate significantly for museum objects, the time-dependent deformation under a constant load of the wood material is of primary interest, i.e. creep (Tsoumis et al. 1991). For static analyses, the elastic properties are needed, but for long-term dimensional stability, also the creep behaviour is necessary for large-sized structures. In this study, the creep behaviour of archaeological oak wood from the seventeenth century Vasa warship (Cederlund and Hocker 2006) has been investigated. Supporting stanchions have been placed inside and outside the hull, but the wooden parts of the ship still carry most of the load. The ship has a mass of 1210 tonnes (Cederlund and Hocker 2006) and the stresses from its mass are distributed through its structural elements to the cradles underneath the hull. The structural integrity of the ship is in principle maintained by the treated archaeological wood, which underwent a reduction of moisture content to equilibrium museum conditions. For the preservation of the ship, it is, therefore, important to investigate the mechanical properties of the Vasa wood. The most important mechanical properties to characterise are the elastic engineering constants and creep properties.

Wood has a variable inherent structure, i.e. even neighbouring wood samples can have very different properties. Different wood species have very different mechanical properties, depending on their anatomy, density, local anisotropy and moisture content (Jozsef et al. 1982). Significant variations can also be seen within species by normal vs. reaction wood, cambial age, etc. When it comes to preserved archaeological wood, the situation becomes even more complicated. A combination of the effects from conservation procedures and degradation results in changes of the mechanical properties compared with those for recent wood. The Vasa ship hull has been conserved by spraying the wood with aqueous solutions of PEG between 1962 and 1979 and then carefully underwent a reduction of moisture content to equilibrium museum conditions before being moved to the present museum in 1989 (Håfors 2001). The PEG serves as a bulking agent which penetrates the wood cell walls and lumens replacing water while drying (Stamm 1959). During the conservation of the Vasa ship, PEG with different average molecular weight (\(M_{\mathrm{w}}\)) (Håfors 2001) has been used. It is important to mention that preservation with PEG results in increased mass density and that usage of, in particular, low molecular-weight (\(M_{\mathrm{w}}\)) PEG (typically <1000 g/mol) results in higher hygroscopicity (Stamm 1974; Gregory et al. 2012). The increased mass of the structure due to the presence of PEG and moisture could thus lead to additional deformations due to self mass.

The elastic, yield and creep properties of Vasa oak are needed for stress analysis and the design of improved support for the ship. The elastic engineering parameters of the Vasa wood have been investigated previously. Tensile elastic properties in longitudinal (L) direction have been investigated by Bjurhager et al. (2012). Compressive elastic properties in radial (R) and tangential (T) directions have been investigated by Ljungdahl and Berglund (2007). Finally, the complete set of orthotropic elastic parameters of Vasa material has been investigated by Vorobyev et al. (2016a,b). These investigations have consistently observed smaller elastic stiffness properties of Vasa material in comparison with those of recent untreated wood. The main reasons for this appear to be the state of degradation of the material and the presence of PEG, which acts as a plasticiser softening the wood cell wall.

The creep properties of the PEG-impregnated archaeological wood material have not been much investigated despite their importance to long-term dimensional stability. Hoffmann (2010) has performed creep and relaxation bending experiments on wooden planks from PEG-impregnated oak wood from the Bremer Cog ship and from sound seasoned oak wood for comparison. The applied stress was 50% from the yield load. This study showed that PEG-impregnated archaeological wood had more pronounced viscoelastic behaviour and larger deformations than the reference wood. The reason was mainly the presence of PEG in the cell wall, acting as a plasticiser and leading to increased deformation of the wood biopolymers under stress. Norimoto et al. (1992) have investigated mechanosorptive creep and relaxation, i.e. creep and relaxation due to changes in relative humidity of PEG-impregnated recent spruce. They reported more mechanosorptive creep in the PEG-impregnated wood samples than in untreated wood and, additionally, a loss of strength.

The objective of the present study is to investigate and discuss the creep response of the archaeological oak wood from the Vasa ship. This knowledge will help predict the time-dependent behaviour of the ship in the museum. The creep properties can be used as input in the finite-element analyses that are necessary for the design process of a future support structure. Additionally, the investigations may be used in a potential optimisation of the museum’s micro-climate. The presented study provides a set of data on the creep response of PEG-impregnated Vasa oak in all orthotropic directions. This information is also relevant for an engineering-based preservation of PEG-treated wooden artifacts in general.

2 Material and method

2.1 Materials

Cubic samples of Vasa and recent oak

The Vasa material was conserved oak wood (Quercus Robur L.) taken from two blocks with museum reference numbers 65742 and 65879. The blocks came from the surface of the hull in the bottom of the ship where holes had been made for ventilation in year 2000. Cubic samples from the same block were studied earlier by Vorobyev et al. (2016a, 2017) to identify PEG content, basic density and orthotropic stiffness coefficients. The studies showed high PEG content, variable basic density and decreased stiffness.

As references, recent oak (Quercus Robur L.) was used. Both the Vasa material and recent wood samples were subjected to mechanical tests and measurements of moisture and PEG contents. First, quasistatic compressive tests were performed to identify the yield stress of the material to decide the stress levels for the creep experiments.

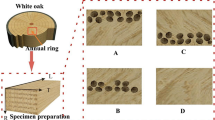

Since the supply of Vasa material was very limited, it was decided to use cubic samples instead of planks for bending or standardised prismatic specimens for compressive testing. With cubic samples, the same specimen can be tested elastically in all three orthotropic directions. The faces of the cubes were carefully machined so that their normals were oriented along the orthogonal anatomical axes of the wood material as well as possible, as shown in Fig. 1.

Samples with the least curvature of the annual rings compared to sample dimensions were chosen to assure relatively uniform material directions within the cube. A length of \(25\pm{0.05}~\mbox{mm}\) has been selected for the edges of the cubes as a fair compromise between the material availability and the representativeness of the wood samples, which should contain a fair amount of the typical microstructural features. Before creep testing, the samples were conditioned in the ventilated box-like measurement compartment below the bowsprit of the ship until moisture equilibrium was attained. The results of the conditioning showed no dimensional change, nor any initial deformation has been registered.

The creep stress levels (\(\sigma_{\mathrm{creep}}\)) were chosen at specific percentages of the yield compressive strength (\(\sigma_{\mathrm {yc}}\)). In this study, \(\sigma_{\mathrm{yc}}\) in the three orthogonal wood anatomical axes (L, T and R) was determined from neighbouring samples from the same wood blocks. The strength values were determined by uniaxial compression of the samples until failure along the three directions. For these destructive tests, the samples had already been used previously in the elastic regime to determine the full set of orthotropic elastic engineering parameters (Vorobyev et al. 2016a,b). The \(\sigma_{\mathrm{yc}}\) in direction L was determined by testing 17 cubic samples of Vasa oak and was 30 MPa with a standard deviation of 7.2 MPa. The corresponding result for the recent oak was determined to be 65 MPa with a standard deviation of 8.3 MPa. At the beginning of the testing campaign, creep characterisation in the R and T directions was not planned, so, in these directions, \(\sigma_{\mathrm{yc}}\) was determined by testing only four samples, i.e. two samples per direction. The average \(\sigma _{\mathrm{yc}}\) was 8.9 MPa (8.68 and 8.93) for the R direction and 5.6 MPa (4.87 and 6.39) for the T direction, which is in agreement with results of Ljungdahl and Berglund (2007).

Plank samples

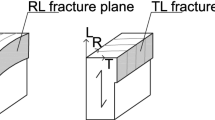

Four larger planks of more than 3 m long were placed in the climate-controlled museum and subjected to four-point bending creep tests. The planks have been cut with the broad side along the TL plane, while some curvature of the annual rings was apparent. The planks were tested in bending in the average R direction (Fig. 2).

Three samples were Vasa material with museum reference numbers 4711, 4720 and 5396, and one was a recent oak plank for reference. Small samples from the corners of the planks were cut to determine the yield strength the PEG content as well as the level of deterioration. These parameters were determined during a previous research project and are presented in full in an internal report (Burman and Ljungdahl 2007). The dimensions and properties of planks are listed in Table 1.

2.2 Mass monitoring

PEG-impregnated samples have a higher hygroscopicity than untreated wood, which will influence their mass fluctuations depending on the varying temperature and relative humidity conditions in the museum during creep testing. It was not practical to measure mass changes in situ to be applied in the creep experiment samples. Therefore, four scales “KernKB 120-3N” containing two small cubic Vasa samples and two recent oak samples were placed next to the creep rig. The mass was registered every minute during the three-year experimental period. The density of these samples is included in Table 3.

To monitor the ambient conditions near the testing rigs, a “Lumel P-18” temperature (\(T\)) and relative humidity (RH) sensor was installed in the measurement compartment. The sensor was calibrated before the initiation of the experiments. Although the climate is well-controlled and stable near the ship, the micro-climate variations in other locations of the museum can be relatively large.

2.3 Creep setup for cubic samples

The creep setup for the cubic samples consisted of three similar and independent creep rigs. Each rig was composed of a metal frame with load cells for five cubic samples (Fig. 3a).

The load cell is shown in Fig. 3b. Each cubic sample was compressed by two aluminium plates and one placed against “ISO 10243” type metal spring with constant elastic stiffness for a large range of deflections. There were two kinds of metal springs used in the experiment. The more compliant Vasa samples were compressed by a “Special springs™ R series R50-064” and the stiffer recent oak samples were compressed by a “Special springsTM A series A50-089”. In this manner, the specimens were subjected to a constant load (i.e. creep conditions), since the spring deflections due to creep deformation of the samples were well within the range of constant stiffness of the springs, which has been determined earlier by testing springs in the universal testing machine.

The top plate was fixed, and the load was applied at the bottom of the samples. The displacements of the bottom plate, corresponding to the sample deformations, were measured by a digital indicator “Mitutoyo ABS Digimatic Indicator ID-C125XB” with accuracy resolution of 1 μm, mounted to the fixed top plate. The accuracy of measurements was 0.001 mm according to the manufacturer. The bottom plates were unable to rotate to allow only axial deformations of the samples. The measurements were logged each minute during the experiments.

The first period of experiments was between 31 January, 2014 and 11 June, 2014. A long run time was necessary since fluctuations in indoor climate have been observed for the annual seasons also from year to year. During this first period, 15 samples were loaded in the L direction at stress levels of 3.0, 6.0 and 9.0 MPa (10%, 20% and 30% of \(\sigma_{\mathrm{yc}}\)). Additionally, for reference, 6 recent oak samples were loaded in the L direction at stress levels of 6.5, 13.0 and 19.5 MPa (10%, 20% and 30% of \(\sigma_{\mathrm{yc}}\)). For these stress levels, the resulting creep strains were in the range where linear viscoelastic behaviour can be assumed for wood (0.5–2% strain for wood (Bodig and Jayne 1982)). There were three rigs (Fig. 3a) which contained five samples each. In each rig, two samples were recent oak, and three were Vasa oak samples.

The second period has started on 11 June, 2014. At that time the Vasa samples, which were loaded in the L direction at 20% and 30% of \(\sigma_{\mathrm{yc}}\), were taken away to make room for other Vasa samples. These samples were loaded in the L direction at the lower stress levels of 1.5 and 4.5 MPa (corresponding to 5% and 15% of \(\sigma_{\mathrm{yc}}\)).

The third period started on 10 February, 2015 until the presented date was acquired on 10 October, 2016. At this time, the recent oak samples were exchanged with six Vasa samples. Three of them were loaded in the R direction with 0.89 MPa and the other three were in the T direction with 0.56 MPa (both 10% of \(\sigma_{\mathrm{yc}}\)). In R and T directions, no recent oak material was subjected to creep. Due to limitations in the available rigs, samples and time, a more comprehensive test program was not feasible, and choices had to be made which tests were most valuable.

2.4 Bending creep rig

The creep rig was built for a four-point bending experiment (Fig. 2). The experimental tests followed the standard D6815-02a (2004) to evaluate creep in planks. While the reference oak plank had a symmetric geometry (rectangular prism), the Vasa oak planks were rather non-symmetric and had different shapes. The centre of mass was determined for each plank and then placed symmetrically at the supports.

The mid-span deflections \(\delta\) were logged by four sets of two digital indicators “ABS Digimatic Indicator ID-C125XB” that were installed on the top and bottom in the middle of each plank. Two indicators were used to distinguish moisture swelling from mechanical deformation (bending). However, thickness changes were difficult to interpret due to warping, in particular, the Vasa planks. To register mass changes, each plank was placed on a “C3 Vishay HPS” load cell with 1 g readability. Initially, the load that was required for obtaining a maximum bending stress of 4 MPa in the planks was approximated using elementary beam theory by

where \(\sigma_{\mathrm{creep}}\) is creep stress (here the maximum bending stress), \(b\) is the width, \(h\) is the thickness, \(L=2500~\mbox{mm}\) is the length between the plank supports and \(a\) is the distance between the two central support lines where the load is applied. Based on recent measurements of the dimensions of the planks slightly different maximum bending stresses were obtained. These creep stresses, as well as the plank parameters, PEG mass percentages and applied loads for all planks, are presented in Table 1. The deflections and loads of all planks were logged every minute during the whole period of investigation.

3 Results and discussions

3.1 Relative humidity temperature and mass fluctuations

The variations of \(T\) and RH with time are shown in Fig. 4. The presented curves were smoothed to daily average values. The daily variations of \(T\) were up to \(1^{\circ}\)C and RH were up to 2%. It is important to notice that the indoor climate conditions in the experimental compartment differed from the average conditions in the surrounding museum. The fluctuations in Fig. 4 do not represent the overall environment in the museum, but are pertinent to the conditions in the proximity of the test samples. The maximum temperature occurs, as expected, during the summers while the maximum RH occurs during the winters. The reason for this is that cooler air needs fewer water molecules to saturate it. So the same absolute amount of water in the air will result in different RH levels at various \(T\) levels (Perry and Green 1999).

The ambient surrounding climate directly affects the wood moisture content. Water vapour in the air migrates in and out of wood samples, changing its mass in the process (Skaar 1988). The relative mass of two Vasa and two recent oak samples are shown in Fig. 5.

It can be observed that the amplitude of the mass fluctuations of the PEG-impregnated Vasa oak samples is larger than that of the recent oak, i.e. the Vasa oak samples are more hygroscopic than the recent ones as also observed by Ljungdahl and Berglund (2007). The impregnation with low \(M_{\mathrm{w}}\) (<1000 g/mol) PEG is known to make the wood more hygroscopic (Bjurhager et al. 2010). It is necessary to mention that low \(M_{\mathrm{w}}\) PEG has a melting point close to museum ambient temperature, i.e., 17–\(22^{\circ}\)C which can be the reason of changes in its physical properties like water activity, thermal expansion, etc. (Korosi and Kovats 1981).

The PEG acts as a bulking agent of the wood cell wall, where it interacts via hydrogen bonds with the cell wall material (Norimoto et al. 1992). It is often considered that the finely dispersed PEG in the ultrastructural nanopores in the cell wall has a minor influence on the hygroscopic properties of the wood due to lack of physical space (Morén and Centerwall 1961). However, it is also possible that the PEG stays in the cell lumen. It happens after the wood cell wall has been saturated. The free PEG in the tracheid lumen and vessel cavities can more quickly absorb water, which increases the hygroscopicity of the impregnated wood sample as compared with samples where only the cell wall contains PEG. It is possible that the samples used for measuring the mass had an excessive PEG in the cell lumen so that increased moisture-induced mass change observed.

Figure 5 also shows that the mass reaches peaks during the winters and minima during the summers. The mass fluctuations correlate with the measured RH in Fig. 4, but not in a precisely linear way. Also, the water activity of PEG-water solutions is known to be nonlinear (Gregory et al. 2012; Ninni et al. 1999; Bjurhager et al. 2010; Rodríguez et al. 2012; Ljungdahl and Berglund 2007).

Assuming that PEG in cell wall shows less hygroscopicity due to immobilisation caused by the surrounding wood biopolymers (Stamm 1956), one can conclude that mainly the PEG in cell lumens is responsible for the increased moisture uptake and mass fluctuations. Assuming that all hygroscopic wood polymers are bound with PEG and only PEG in the cell lumen is in charge of all moisture absorption, it is possible to estimate the amount of PEG in the cell lumen from the mass oscillations in the variable climate. It can be a useful tool in determining the amount of PEG needed to stabilise wood without severely affecting its hygroscopicity beyond the saturation point (Stamm 1974).

In the case of Vasa oak, PEG batches with different average \(M_{\mathrm {w}}\) have been used, and it is hard to estimate the precise amount of PEG in the cell lumen. If the total PEG content and amount of PEG in cell lumen are known, the amount of PEG in the cell wall acting as plasticiser could be estimated. For a more precise analysis, the relative amount of PEG in the lumen and the cell wall should be distinguished.

3.2 Creep in cubes in longitudinal direction

The present study aims to characterise creep behaviour and identify an acceptable level of stresses on Vasa oak with high PEG contents. Figures 6a–e show creep curves of Vasa oak cubical samples for different stress levels and Fig. 6f shows the corresponding creep curves of reference oak. Due to the high stiffness in axial direction a very small strains are obtained. This leads to step-like curves in the figures due to the resolution of the digital indicator “Mitutoyo ABS Digimatic Indicator ID-C125XB”. Note that positive values in the strain directions mean compressive creep strain.

From Fig. 6f, it is clear that no measurable creep was detected for recent oak using the selected applied loads, except the sample loaded with 30% of \(\sigma_{\mathrm{yc}}\). It can be observed that during the summer period, the samples are even expanding against compressive load direction. This aspect will be discussed later in the text. Swelling due to moisture is not the case here because according to Fig. 6, summer periods had lower RH.

In contrast, the Vasa oak curves show a clear creep effect. Although the scatter is quite large, there is a clear trend showing increasing creep deformation for increasing stress levels. The significant variability is manifested in the big differences in creep amplitude in Figs. 6b–e.

The curves corresponding to 5% of \(\sigma_{\mathrm{yc}}\) load level in Fig. 6a show very slow development of creep strains. This means that this stress level has the lowest effect among others, on the creep deformation of the Vasa wood. On the other hand, samples 12 and 13, which were loaded at 20% and 30% of \(\sigma _{\mathrm{yc}}\) visualised in Figs. 6d-e show relatively large strains that will most likely result in a destruction of the samples. Therefore, a load level of 10% or 15% of \(\sigma _{\mathrm{yc}}\) appears to be a good compromise between these two observations.

Creep curves can show either primary creep, i.e. the strain approaches a constant level, secondary creep, i.e. the strain rate approaches a constant level, or even tertiary creep, where the strain accelerates until failure (Tsoumis et al. 1991). For many of the presented experimental curves, however, the measurement period may not be sufficiently long to draw conclusions.

Most of the measured samples appear to show either primary or secondary creep. Samples 10, 13, 17 and 19 seem to approach a constant strain, i.e. primary creep. Samples 7, 9, 11, 12, 14, 16, 19, 20, 23 and 24 appear to approach a constant strain rate, i.e. secondary creep. For almost all samples except one (sample 13) the secondary creep is observed below 2% strain. The samples loaded at 10% of \(\sigma _{\mathrm{yc}}\) in Fig. 6b were monitored for the longest period, almost three years. After approximately half a year, the creep curves of samples 7 and 9 exhibited secondary creep. It is observed that in some samples secondary creep goes below 2% strain. Sample 8, on the other hand, does not show a clear creep response at all. Note also that sample 14 that was loaded with 15% of \(\sigma _{\mathrm{yc}}\), shown in Fig. 6c, is also clearly affected by the changing ambient conditions.

To compare the creep behaviour of different samples, creep compliance \(J(t)\), i.e. creep strain divided by the constant stress (Tweedie and Van Vliet KJ 2006), was used. It is well known that creep compliance \(J(t)\), which is commonly used for a linear viscoelastic material, is invariant with applied stress. A measurable and practical test to establish whether wood material has linear viscoelastic behaviour is to check if \(J(t)\) depends on the applied stress or not (Bodig and Jayne 1982).

Figure 7 shows creep compliance curves for Vasa oak. Even though the stiffness of the samples is unknown, from Figs. 7a–b it can be seen that for a reasonable number of samples the creep compliance curves are quite similar. For clarification, the most similar curves have been replotted in Fig. 7c. Assuming that the stiffness of these archaeological wood samples is similar, a conclusion can be drawn that a linear viscoelastic creep model could be used to describe the creep behaviour at lower stress levels. From Figs. 7a–b, it is also apparent that a significant number of curves show much higher creep compliance. Assuming similar stiffness again, this may happen when the stress is too large, causing increasing creep deformations.

It is hard to quantify the effect of PEG impregnation on the time-dependent behaviour in the L direction. However, it is worthwhile to consider that all samples have PEG mass percentages of at least 25%, which means that the wood cell wall is most likely fully saturated with PEG (Stamm 1956; Ljungdahl and Berglund 2007). The present results indicate that longitudinal stress levels up to 10% of the \(\sigma_{\mathrm{yc}}\) could be acceptable since the creep strains remain limited. Higher compressive stress levels are likely to result in larger deformation, possibly beyond linear and reversible behaviour.

3.3 Creep in cubes in radial and tangential directions

Creep in the T and R directions has also been studied in the current investigation. The results are presented in Fig. 8. The specimens were loaded in compression, and a positive strain signifies compressive deformation. In contrast with the longitudinal direction given above, variations in ambient conditions have a relatively significant influence on the time-dependent response in these directions.

For several of the samples, negative strains can be observed, indicating unexpected expansion in the direction opposite to the loading direction. As a first thought, one could attribute this strange behaviour to hygroexpansion (swelling). However, hygroexpansion can be ruled out since the maximum RH, displayed in Fig. 4, takes place during the winter months, corroborated by the moisture-induced mass changes in Fig. 5, in contrast to the maximum expansion which occurs during the summer months. Further explanation is given later in text.

It is well known that the mechanical properties (i.e. Young’s modulus, compressive strength, etc.) of the wood decrease with increasing moisture content. Moreover additional moisture can also induce increased creep in wood samples (Hoffmeyer and Davidson 1989). Indeed, increasing compressive deformation is prompted by the humid ambient conditions during winters as shown by the peaks in compressive strain in Fig. 8.

For separating the effect of the climate changes from the creep behaviour, a mathematical fitting procedure was applied to the strain measurements. The strain was separated into three parts: a constant part (due to the initial elastic deformation), a part involving an exponential function (due to pure creep deformation) and a part directly related to the average mass change of the samples (due to moisture-induced swelling and softeningFootnote 1). The resulting fitting equation becomes

where the fitting variables are \(\varepsilon_{\mathrm{e}}\), \(\varepsilon _{\mathrm{c}}\), \(\varepsilon_{\mathrm{m}}\) (the magnitudes of the strain due to the initial elastic, creep and moisture-induced deformation, respectively) and \(\tau\) (the creep time constant). The function \(w(t)\) is the average of the normalised mass changes as displayed in Fig. 9 (modified to start at zero). The fitting procedure was performed using the constrained optimisation algorithm in MATLAB with appropriate bounds. An example of the fitting procedure is included in Fig. 9, showing the decomposition of the total strain into an initial elastic, creep and moisture-induced part. In this fitting procedure, the part of the strain that was constant was defined as elastic and the exponential decaying part was defined as creep. However, in reality the creep deformation and dimensional changes due to moisture fluctuations are not necessarily independent.

Figure 10 shows the results of the fitting procedure. The pattern of measured strain and fitted strain in Fig. 10 illustrate how much correlation exists between the measured strain, due to creep and thermo-hygroexpantion, and changes of the moisture content. It can be observed that in samples 2 and 18 creep is hardly happening during the first days after load was applied. The rest of the samples show no creep and were only affected by the ambient conditions.

Creep curves of cubical samples of Vasa oak loaded in radial and tangential directions. The total fitted strain shows the indirect effect of ambient conditions and was calculated using the mass change data in Fig. 5

Table 2 was compiled to show the trends on the deformation of the PEG-impregnated Vasa oak samples in the R and T directions. As mentioned before, the deformations in winter are clearly correlated with the changes in moisture.

It is hypothesised that the decreasing deformation (i.e. expansion in the direction opposite to the compressive loading direction) during the summers is temperature-induced thermal expansion or stiffening effect of the material due to decreased moisture content (Bodig and Jayne 1982).

Thermal expansion of untreated wood is very small in comparison to moisture-induced swelling (Tsoumis et al. 1991). However, the thermal expansion coefficient \(\alpha\) of PEG is orders of magnitude greater than that of oak wood. Assuming that the one-dimensional and volumetric thermal expansion coefficients, \(\alpha_{\mathrm{lin}}\) and \(\alpha_{\mathrm{vol}}\), are related as \(\alpha_{\mathrm{vol}}=3\alpha _{\mathrm{lin}}\) (Cverna 2002), then the one-dimensional thermal expansion coefficients of PEG 600 and PEG 1000 are \(2.4\times 10^{-4}\) and \(2.4\times10^{-4}~\mbox{K}^{-1}\), respectively (Korosi and Kovats 1981), while for wood in the R and T direction these are \(11.1\times10^{-6}\) and \(54.4\times10^{-6}~\mbox{K}^{-1}\), respectively (Kollmann et al. 1968; Stevens et al. 1960). The presence of PEG in the Vasa oak wood cell wall may increase its thermal expansion, provoking expansion or contraction in the R and T directions due to temperature changes. Since PEG acts as a bulking agent in the wood cell walls (Stamm 1974; Hoffmann et al. 2013), its thermal expansion may have a direct effect on dimensional changes of the PEG-impregnated Vasa material as a whole.

Finally, the strain development of the samples in Fig. 8 shows an annually decreasing trend (increasing expansion). The strains in the summer of 2016 are lower than the strains in the summer of 2015, indicated a deformation opposite to the compressive loading direction. Two hypotheses can be suggested for this behaviour: (1) The ambient conditions, RH or \(T\), are also changing over the years (see Fig. 4), i.e. the RH and \(T\) have a wide span between maximum and minimum values; (2) The “reversible swelling” (Ugolev et al. 2010) is present in the Vasa material, i.e. accumulated internal stresses are being released due to annual oscillations of RH and \(T\). Only sample 18, which was cut from a different initial block (Table 3), shows strain oscillations with increasing annual deformation.

3.4 Creep in planks

The creep behaviour of planks in four-point bending is presented in Fig. 11a. All four planks have quite a different response. In particular, the deflection of plank 4720 (Vasa oak) shows an atypical creep curve. This plank has a relatively low PEG content and showed some visible warping at later stages during the creep test. The curve has still been included in this study since experimental creep results are scarce for this type of material.

The other planks behave as expected and show creep-like behaviour. In Fig. 11a, it can be seen that the planks 4711 and 5396 (Vasa oak) have deflections which are in the same range. The creep rate of the reference plank is higher during the summer of 2016. The same pattern can be seen for plank 4711. In contrast, plank 5396 shows a lower creep rate in that period and higher creep rates during the winters, which is most likely moisture-induced. A linear viscoelastic response was compared using a creep compliance \(J(t)\) that was calculated using beam theory as

and presented in Fig. 11b for three planks. The results showed that two Vasa oak planks 4711 and 5396 have a similar creep compliance \(J(t)\), while the reference plank shows less creep. Hoffmann (2010) also observed less creep in recent wood compared with PEG-impregnated archaeological wood. It can be seen in Fig. 11b that Vasa planks are not showing primary creep behaviour in this time range, but rather secondary creep with constant creep rate. The \(\sigma_{\mathrm{creep}}\) of 3.6 MPa for plank 4711 and 5.7 MPa for plank 5396 (12–14% of \(\sigma_{\mathrm {yc}}\)) resulted in a secondary creep deformations in the planks made of Vasa oak.

The mass changes of two of the planks are presented in Fig. 12. Plank 5396 is not shown due to a failure in the logging system during the experiment. However, it can be seen that the mass changes of 4711 and of the reference plank are affected by the annual fluctuations in the ambient conditions. From Fig. 12, a slight delay in the moisture uptake of the Vasa oak plank can be observed as compared with the reference plank. It is known that PEG-impregnated wood is more hysteretic than recent wood (Bjurhager et al. 2010). This might describe the delay in the moisture uptake. It is possible that the diffusion coefficient of the Vasa oak is higher than that for the recent oak. This phenomenon, however, is not observed for the cubical samples in Fig. 5 due to their even dimensions in all planes.

4 Conclusions and recommendations

Several conclusions can be drawn from the present study, keeping in mind the low number of specimens. The variable ambient conditions have a higher impact on mass, and therefore on moisture content, of wood with high PEG content. Cell lumen and vessel cavities can be filled with PEG, which results in significantly increased moisture-induced mass changes during the annual variations in climate. The mass changes observed for the Vasa oak cubic samples are higher than for recent oak.

The creep phenomena in the L direction of Vasa oak samples have scattered response for the stresses between 15% and \(30\%\) of the \(\sigma_{\mathrm{yc}}\). Some samples of Vasa oak show similar creep compliance curves, with secondary creep, i.e. approaching a constant creep rate. Almost all Vasa oak samples loaded in axial direction showed secondary creep below 2% strain. Recent oak samples loaded within the same range of the stresses in the stiff L direction were not showing any significant creep. For the Vasa oak loaded in the T and R directions, the creep behaviour is dominated by the effect of annual fluctuations in moisture and temperature on the strain. With the stresses of \(10\%\) of the \(\sigma_{\mathrm{yc}}\) two of six samples showed insignificant creep response.

The PEG-impregnated Vasa oak planks showed a similar time-dependent response in four-point bending. The planks showed additional deflections that were induced by the change of annual fluctuations in moisture and temperature. The recent oak plank showed smaller overall deflections. The mass changes in planks showed same as the behaviour of the cubic samples during annual fluctuations of ambient conditions.

A deeper study of the following subjects can be the scope of future work: (1) Additional experimental study in creep behaviour is needed on the samples with low or zero PEG content; (2) The effect of RH and/or \(T\) on creep phenomena of PEG-impregnated wood in all orthotropic directions; (3) The impact of PEG impregnation on the coefficient of thermal expansion of wood.

Notes

Note that swelling and softening have opposite effects on the strain, but both are directly related to the moisture content of a sample.

References

Bjurhager, I., Ljungdahl, J., Wallström, L., Gamstedt, E.K., Berglund, L.A.: Towards improved understanding of peg-impregnated waterlogged archaeological wood: a model study on recent oak. Holzforschung 64(2), 243–250 (2010)

Bjurhager, I., Halonen, H., Lindfors, E.L., Iversen, T., Almkvist, G., Gamstedt, E.K., Berglund, L.A.: State of degradation in archaeological oak from the 17th century Vasa ship: substantial strength loss correlates with reduction in (holo) cellulose molecular weight. Biomacromolecules 13(8), 2521–2527 (2012)

Bodig, J., Jayne, B.: Mechanics of Wood Composites. Von Nostrand Reinhold Company, New York (1982)

Burman, M., Ljungdahl, J.: Krypprovning av trämaterial. Technical report, KTH Royal Institute of Technology (2007)

Cederlund, C.O., Hocker, F.M.: Vasa I: The Archaeology of a Swedish Warship of 1628. National Maritime Museum of Sweden, Stockholm (2006)

Cverna, F.: Thermal Properties of Metals. ASM International, Materials Park (2002)

D6815-02a, A.: Standard specification for evaluation of duration of load and creep effects of wood and wood-based products. Standard, ASTM International, West Conshohocken, PA (2004). https://doi.org/10.1520/D6815-02A

Gregory, D., Jensen, P., Strætkvern, K.: Conservation and in situ preservation of wooden shipwrecks from marine environments. J. Cult. Heritage 13(3), S139–S148 (2012)

Håfors, B.: Conservation of the Swedish warship Vasa from 1628. Vasamuseet (2001)

Hoffmann, P.: On the stabilization of waterlogged oakwood with polyethylene glycol (PEG) III. Testing the oligomers. Holzforsch.-Int. J. Biol. Chem. Phys. Technol. Wood 42(5), 289–294 (1988)

Hoffmann, P.: On the long-term visco-elastic behaviour of polyethylene glycol (peg) impregnated archaeological oak wood. Holzforschung 64(6), 725–728 (2010)

Hoffmann, P., Bojesen-Koefoed, I., Gregory, E.D., Jensen, P.: Conservation of archaeological ships and boats: personal experiences. Archetype Publications (2013)

Hoffmeyer, P., Davidson, R.: Mechano-sorptive creep mechanism of wood in compression and bending. Wood Sci. Technol. 23(3), 215–227 (1989)

Jones, A., Rule, M., Jones, E.: Conservation of the timbers of the tudor ship Mary rose. In: Biodeterioration 6. Papers Presented at the 6th International Biodeterioration Symposium, Washington, DC, August 1984, pp. 354–362. CAB International, Wallingford (1986)

Jozsef, B., et al.: Mechanics of Wood and Wood Composites. Krieger, Melbourne (1982)

Kollmann, F., Côté, W., Kuenzi, E., Stamm, A.: Principles of Wood Science and Technology: Solid Wood. Springer, Berlin (1968)

Korosi, G., Kovats, E.S.: Density and surface tension of 83 organic liquids. J. Chem. Eng. Data 26(3), 323–332 (1981)

Ljungdahl, J., Berglund, L.A.: Transverse mechanical behaviour and moisture absorption of waterlogged archaeological wood from the Vasa ship. Holzforschung 61(3), 279–284 (2007)

Morén, R., Centerwall, B.R.: Use of polyglycols in the stabilizing and preservation of wood. Meddeland en Frän Lunds Universitets Historiska Museum, pp. 176–196 (1961)

Ninni, L., Camargo, M., Meirelles, A.: Water activity in poly (ethylene glycol) aqueous solutions. Thermochim. Acta 328(1), 169–176 (1999)

Norimoto, M., Gril, J., Rowell, R.M.: Rheological properties of chemically modified wood: relationship between dimensional and creep stability. Wood Fiber Sci. 24(1), 25–35 (1992)

Perry, R.H., Green, D.W.: Perry’s Chemical Engineers’ Handbook. McGraw-Hill, New York (1999)

Rodríguez, G.A., Holguín, A.R., Martínez, F., Khoubnasabjafari, M., Jouyban, A.: Volumetric properties of (PEG 400 + water) and (PEG 400 + ethanol) mixtures at several temperatures and correlation with the Jouyban–Acree model. Rev. Colomb. Cienc. Quim. Farm. 41(2), 187–202 (2012)

Skaar, C.: Hygroexpansion in Wood, pp. 122–176 Springer, Berlin (1988). https://doi.org/10.1007/978-3-642-73683-4_4.

Stamm, A.J.: Dimensional stabilization of wood with carbowaxes. For. Prod. J. 6(5), 201–204 (1956)

Stamm, A.J.: Effect of polyethylene glycol on the dimensional stability of wood. For. Prod. J. 9(10), 375–381 (1959)

Stamm, A.J.: Dimensional stabilization of wood with water soluble fire retardant bulking chemicals compared with polyethylene glycol-1000. Wood Sci. Technol. 8(4), 300–306 (1974)

Stevens, W., et al.: The thermal expansion of wood. Wood 25(8), 328–329 (1960)

Tsoumis, G., et al.: Science and Technology of Wood: Structure, Properties, Utilization, vol. 115. Van Nostrand Reinhold, New York (1991)

Tweedie, C.A., Van Vliet, K.J.: Contact creep compliance of viscoelastic materials via nanoindentation. J. Mater. Res. 21(06), 1576–1589 (2006)

Ugolev, B., Galkin, V., Gorbacheva, G., Kalinina, A.: Frozen shrinkage of wood. Wood Struct. Prop. 10, 73–77 (2010)

Vorobyev, A., Arnould, O., Laux, D., Longo, R., van Dijk, N.P., Gamstedt, E.K.: Characterisation of cubic oak specimens from the Vasa ship and recent wood by means of quasi-static loading and resonance ultrasound spectroscopy (RUS). Holzforschung 70(5), 457–465 (2016a)

Vorobyev, A., Bjurhager, I., van Dijk, N.P., Gamstedt, E.K.: Effects of barrelling during axial compressive tests of cubic samples with isotropic, transversely isotropic and orthotropic elastic properties. Compos. Sci. Technol. 137, 1–8 (2016b)

Vorobyev, A., Almkvist, G., van Dijk, N.P., Gamstedt, E.K.: Relations of density, polyethylene glycol treatment and moisture content with stiffness properties of Vasa oak samples. Holzforschung 71(4), 327–335 (2017)

Acknowledgements

This work was performed as part of the research program “Support Vasa”, which is financially supported by the Swedish National Maritime Museums (SMM), the Swedish Research Council (VR), the Swedish Research Council for Environment, Agricultural Sciences and Spatial Planning (FORMAS) and The Swedish Agency for Innovation Systems (VINNOVA). This support is gratefully acknowledged, as well as the financial support from the Uppsala University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Vorobyev, A., van Dijk, N.P. & Kristofer Gamstedt, E. Orthotropic creep in polyethylene glycol impregnated archaeological oak from the Vasa ship. Mech Time-Depend Mater 23, 35–52 (2019). https://doi.org/10.1007/s11043-018-9382-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-018-9382-3