Abstract

Nowadays blockchain technology plays a vital role in creative developments and important discoveries in the world. Blockchain develops secure and trustworthy platforms for data sharing in various application areas such as secure sharing of medical data, Anti-money laundering, tracking systems, Supply chain, and logistics monitoring, Crypto-currency exchange, etc. Today’s Supply chain in the healthcare sector faces many problems like security, transparency, tampering with medical products, counterfeit drugs, more paperwork, high cost, and more time-consuming process while transporting medical equipment from manufacture to end-users. To overcome these problems, we introduce Novel Approach for Integrated IoT (Internet of Things) With Blockchain in Health Supply Chain (NAIBHSC) approach. By using this approach, we can eliminate all supply chain-related issues between suppliers and end-users. The goal of this research is by combining Blockchain technology with IoT to develop a smart health supply chain management system. This approach provides security, privacy, trust, visibility, decentralized tracking and tracing of the medical product, avoids counterfeit drugs, avoids the damage to medical components, authentication, reduces the cost, and provides the status of the products during the shipment process between manufacturers to end-user. In this approach, we conduct a series of experiments on a different group of users. The experimental results show that compare to existing approaches our proposed NAIBHSC approach gives better response time that is the average Transaction Per Second (TPS) for a group of 500 users is 100 milliseconds, reduces the latency time that is average latency time for 500 users group has 403 milliseconds, and improves the overall performance of the smart health supply chain management system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Healthcare Supply Chain Management (HSCM) system plays a very crucial role for transfer medical products from source to end-users. The supply chain in healthcare is the logistics of surgical, medical, and pharmaceutical supplies [32]. Nowadays, healthcare supply chain management systems face many problems while transporting medical types of equipment from manufacturers to end-users [23].

The following are some of the issues in the health supply chain management system:

-

Strong cryptographic techniques are required in smart transportation to ensure that data and information are not tampered with by an unauthorized user; as a result, an effective vehicle identification technique is required.

-

It must ensure that the message is delivered to the correct recipient.

-

Another issue is availability, which means smart gadgets must be available 24 h a day, seven days a week.

-

Nowadays some supply chain systems use IoT devices during the transport of medical devices. The major drawback is, that IoT devices are having limited storage and processing power, they are good targets for security assaults. Effective security and privacy solutions are essential.

-

A smart supply chain requires delivering the products to the correct person right time and right place, which is only feasible with a secure infrastructure.

-

Tracking of medical components throughout the supply chain network becomes a major problem due to centralized control, lack of accurate information, and competing behavior between stakeholders [12].

-

Healthcare supply chains have a complex structure it connects various organizations and various geographical boundaries, due to this complex nature tracing, transparency, and accuracy of information become a major problem [2].

-

Counterfeit drugs are become the major barrier in the present healthcare supply chain management system, because of counterfeit drugs so many people have lost their lives and also an economic loss to the healthcare industries [4].

To overcome these problems the health supply chain management system adapts new technologies to improve security, trust, tracking and tracing, visibility, and improve efficiency [8].

1.1 Contribution of work

The healthcare supply chain management system plays an important role in the development of the country. The supply chain involves different stockholders and participants to perform various operations between suppliers to the customer [43]. The existing supply chains become more complex due to a greater number of participants, increased volumes of data, and also reduced efficiency. To address these issues we propose a novel approach for efficient distribution of medical products between companies and end-users. This work’s novelty includes:

-

1.

Develop NAIBHSC approach by Integrating IoT with Blockchain in Health Supply Chain management system to supply medical products securely and effectively between corporations and end consumers.

-

2.

Create smart contracts to make invoicing, payments, and physical product shipping more cost-effective, auditable, and automated.

-

3.

Create RFID tags for each product; these tags are used to perform scanning and track the flow of products through each stage.

-

4.

In this approach we create a supply chain network to reduce the number of undamaged goods during product transportation from the manufacturer to the end-user.

-

5.

In this approach we used a Bi-objective mathematical model to minimize the destination cost and reduce the number of undamaged items during the transport of the product from manufacture to end-user.

-

6.

Perform a series of experiments to compare the existing system with the proposed system to increase response time and reduce latency.

1.2 Motivation

The goal of this research is to give an overview of how Blockchain technology and the Internet of Things might help supply chains become more sustainable. The motivations are in line to create a secure, long-term, efficient, and transparent health supply chain.

The following is how the rest of the paper is organized:

The literature review of existing health supply chain management systems is presented in Section 2. Section 3 discusses supply chain network design and how to compute product traceability in a supply chain network. Section 4 discusses the proposed NAIBHSC method, including its architecture and benefits. The software implementation of the proposed approach is covered in Section 5. Section 6 compares the proposed approach to the existing approach and analyses the results. The article’s conclusion is discussed in Section 7.

2 Literature survey

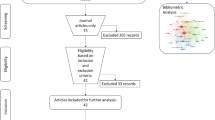

In this section first, we provide basic information about blockchain, and then describe the role of IoT in the health Supply chain. Next, we describe the role of blockchain in the Healthcare Supply Chain Management (SCM) System and followed by Blockchain Integrate with IoT in Healthcare Supply Chain, finally we provide a literature review of different papers related to the supply chain management system.

2.1 Blockchain

Blockchain innovation is thought for its software in Bitcoin digital currency which is an open record for making and keeping up exchange information and trustworthiness [40]. Blockchain provides distributed decentralized data sharing among authorized users in a network [14]. Blockchains consist of collections of blocks, each block connected with the previous block and forms like a chain [5]. In blockchain for each transaction, it provides the acknowledgment for providing tamper-proof and integrity of data. The acknowledgment consists of the transaction ID [21]. By using transaction-id, we can easily identify the location and those transaction block details. Blockchain provides fault-tolerant data sharing; by using this we can easily eliminate compromised nodes within the network [17]. Blockchain provides more security, transparency, and trust to the user’s data [15]. Tampering of data within the blockchain is a very difficult task because each block in the network is connected with the previous block and each block is encrypted with hash values and timestamps [16]. In a blockchain network, once the block is created that was verified by the Miners in the networks [9, 28, 39]. The role of Miners is to perform Proof-of-Work mathematical operations which are used to verify and approve the block (https://robbreport.com/lifestyle/finance/bitcoin-founder-satoshi-nakamoto-1234613022).

In the blockchain, smart contracts play a very curtail role in data exchange between different participants in the network (https://www.icaew.com/technical/technology/blockchain/blockchain-articles/what-is-blockchain/history). Smart contracts are computer programs that help execute the transactions, and store the distributed data. Smart contracts are not just a program, they are useful for providing agreement between participants in the network (https://www.leewayhertz.com/blockchain-in-pharma-supply-chain/). Smart contracts contain scripts with a unique address so that we can easily perform validation and traceability with push notifications to minimize human interaction and avoid delays in the network [20]. Blockchain provides various advantages to the users, the major advantages of blockchain are decentralized data sharing between authorized users in the network, provide transparency of user’s data stored in the network, availability of resources, Immutability, security, permissionless, and trust [10, 11].

2.2 Role of IoT in the health supply chain

The Internet of Things (IoT) is a network of massively interconnected devices (digital and mechanical machinery, items, and so on) with unique IDs. These devices can send and receive data over the internet. IoT devices, in a nutshell, can sense and gather data and send it via the Internet. Transportation and logistics play a critical role in any society’s progress [19, 37]. The economy and community benefit from goods transportation and logistical networks. By connecting the huge objects engaged in transportation and logistics, the Internet of Things has revolutionized the area. Online tracking, traffic control, avoiding traffic congestion, condition monitoring, offering an efficient supply chain, and prompt decision making are some of the advantages that IoT has brought to the industry of transportation and logistics [19]. Figure 2 depicts a smart transportation and logistics concept in which a large number of IoT devices are intelligently connected and monitored and tracked in real-time. IoT joins these disparate things together via embedded sensors, actuators, and other devices to collect and transmit real-time data on network activity.

2.3 Supply chain management (SCM) system in healthcare with blockchain

Supply chains are everywhere. The supply chain in healthcare is the logistics of surgical, medical, and pharmaceutical supplies [37]. It also includes the supplies of medical devices, medical and laboratory equipment, and other items, products, and pieces of equipment to support dentists, doctors, veterinary physicians, nurses, and other healthcare providers [3]. The supply chain involves different stockholders and participants to perform various operations between suppliers to the customer [43]. The existing supply chains become more complex due to a greater number of participants, increased volumes of data, and also reduced efficiency [25].

Today’s supply chains include a tremendous amount of paperwork, which is both time-consuming and costly [30]. In addition to that, the ease of tampering with data in the current system results in counterfeit products getting into the chain of original products [1]. To avoid such problems SCM uses smart contracts that can be used to automate business rules and process the transactions [22]. The above Fig. 1 describes a health supply chain management system with blockchain it consists of several phase suppliers, factors, Data Centers (DC), Regional Data Centers (RDC), Retailers, and end-users. In each phase perform various transitions each transaction is stored in the blockchain network in the form of a block [13]. Suppliers send the raw materials to the factory, factories manufacturers create the products, the products will distribute to Data Centers, Data Centers send these products to Regional Data Centers (RDC), the RDC sends the products to the Retailers, and finally, the retailers send the products to the end-user [35]. The transactions performed between the phases are recorded and maintained in time stamps and verified by the smart contracts [9]. Smart contracts are the programs that specify the condition for validating every transaction in the network [24]. A smart contract is recognized by an address and its source code is stored on the blockchain [7]. The major advantages of integrating smart contracts in blockchains are effective tacking the products, automatic payment process, reduce transportation costs and increase Trust [38].

2.4 Blockchain integrate with IoT (internet of things) in healthcare supply chain

Blockchain technology brings more advantages and reduces human interaction throughout the healthcare supply chain management system. Because of blockchain technology, the SCM system process significantly improved. During the transfer of healthcare products, SCM faces lots of problems like counterfeiting or theft of medical products, bills of lading, or ship notifications [6]. To avoid such problems SCM uses blockchain technology to transfer the medical product from manufacturer to customer. Blockchain creates a digital token, which is attached to healthcare products to protect from various counterfeiting or theft of medical products [5]. The customer receives the products based on authentication provided by the token and he/she confidently receives the product without altering or accessed by unauthorized users. Blockchain provides a digital distributed ledger system; once data enter the blockchain network it cannot be altered [31]. In supply chains, by using smart contracts we can provide security and reduce the cost by automating the supply chain process but efficiencies and product monitoring become a major problem [33, 34, 41].

To avoid these difficulties in this paper, we introduce integrating IoT (Internet of Things) with blockchain though-out the SCM system [29]. The above Fig. 2 explains the combination of IoT in the SCM; it provides continuous data flow between manufacturers to end-users during transit. It provides real-time tracking products, and monitoring operations, and performs analytics operations like alerts, and delay conditions. IoT is a network of connected physical devices that are fixed with software, electronic devices, a set of connections, and various sensors, Quick Response (QR) codes, Radio-Frequency Identification tags, and barcode systems that are allowed to collect and exchange data. The data collected from the sensors can be stored, analyzed, and provided for decision-making to the various stack holders throughout the health supply chain. Integrating IoT with blockchain provides various benefits to the health supply chain management system, which include effective traceability of products, increase data security, process optimization, and counterfeits management in the HSCM [42].

Different types of research have proposed different approaches to blockchain in supply chain management systems. Rim Ben Fekih et al. [13], discusses the comprehensive study on various applications of Blockchain in healthcare. In this paper author mainly identifies various applications of blockchain, remote patient monitoring, sharing electronic health records, and drugs using the supply chain. Singh B et al. [38] presents a survey on blockchain applications and challenging Risks. In this paper, the author provides various blockchain concepts and different challenging issues are discussed. The author also discusses various blockchain-based ecosystems and the associated security mechanisms in existing approaches. The authors IsraaAbu-elezz et al. [20] Provide a review of blockchain-based healthcare system benefits and threats. The authors concentrate on improving the interoperability of patient health information and improving the privacy and security of patient data. Rohit Raj et al. [35], proposed an approach to avoid the counterfeit drug in SC Anti-counterfeiting in Pharmaceutical Supply Chain by providing Proof of Ownership. In this approach, the author develops a permission blockchain through which only authorized users join the network and perform various transactions to the blockchain. By using this approach, we can avoid counterfeiting drugs during Pharmaceutical Supply Chain. Fariba Goodarzian et al. [17] Proposed a Medical SC model during COVID-19. This model provides problems that occurred during the sustainable HSCM system. The authors identify the gaps in HSCM for distributing the medical information to the COVID-19 patients. In this paper, the authors also focus on various HSCM systems-related problems like multi-objective, multi-level, multi-product, and multi-period. To avoid all the HSCM-related problems the author develops a meta-heuristic algorithm by integrating with different (ant colony optimization, fish swarm, and firefly) algorithms. Alizadeh et al. [4] Proposed a Forward and reverse supply chain-based approach to avoid biological risks during the SC network. In this approach, the author concentrates on increasing the profit obtained from the revenues of the SC and reducing biological risks. Thomas Bocek et al. [5], proposed “Blockchain everywhere - A Use-case of Blockchain in the pharmacy supply chain”. In this approach, the author proposed modum.io a set-up that integrates IoT with blockchain to provide data accessibility, and immutability, and reduce the operational cost in the HSCM system. In this approach, the author mainly focuses on heat sensors while transferring the product during the supply chain to fully ensure GDP regulations. SR SR Bryatov et al. [6] Proposed “Blockchain technology in the pharmaceutical supply chain: researching a business model based on Hyper-ledger Fabric”. In this approach, the authors mainly focus on medical turnover control systems using blockchain. This approach using the Hyper-ledger creator development environment was investigated. The authors F Jamil et al. [21] Proposed “A novel medical blockchain model for drug supply chain integrity management in a smart hospital”. In this approach, the authors develop a Hyperledger Fabric blockchain-based novel drug SCM to create a smart healthcare ecosystem with a drug supply chain. In this approach, the authors try to improve the throughput and minimize the latency time. The major drawback of this application is it gives better results for small-sized networks. Edvard Tijan et al. [40], provide the review of blockchain-based logistics current trends and usage and medical supply chain management system. Ahmad Musamih et al. [32], proposed “A Blockchain-based Approach for Drug Traceability in Healthcare Supply Chain”. In this approach, the authors provide an Ethereum-based blockchain with includes smart contracts and provide decentralized data sharing during the health supply chain. In this approach, the author performs testing and validation, and security analysis, and also enhances traceability within pharmaceutical supply chains. The authors Manavalan E et al. [30]. presents a review of IoT embedded with the SC for Industrial 4.0 requirements. In this paper, the authors provide a complete study on different factors, that involves sustainable SC were examined and the results are recorded. M. Abdel-Basset et al. [22] proposed IoT based supply chain management system-based website was created. By using RFID technology, they attached the RFID tags to the products and perform scanning and track the flow of products in each stage by using RFID tags to provide the security they create a framework. In the paper [8] the author Costa C et al. Proposed RFID based Agriculture food SC system. In this paper, the author analyzes the existing developments in RFID technology in the agriculture food SCM system to provide fast and secure manage the supply chain. Cameron Faulkner [12], proposed an approach for health supply chain management system using Near Field Communication (NFC) tags. In this approach, every product is registered and authenticated with key values, and each product is attached with NFC tags throughout the supply chain. The end-user can verify the authenticity of each product by scanning the NFC tags. Tseng et al. [41] proposed drug SC approach through the Gcoin blockchain. In this paper authors proposed transparent drug transaction data flow based on the Gcoin blockchain. The Gcoin blockchain provides immutable, consensus-driven, and transparent drug SC transaction data establishment and provides security. Yan Huang et al. [18] proposed Blockchain-based drug traceability and a ruling system named Drug-ledger. The drug ledger reconstructs the entire job structure via isolating service providers of ternary unbiased service aspects and ensures authentication, traceability, and privacy. Drugledger could correctly prune stable and acceptable blockchain storage. In this approach real drug supply chain logic is designed workflow based on the expanded UTXO (Unspent Transaction Output). The authors Shuchih Ernest Chang et al. [7] Proposed a blockchain-based SC re-engineering framework integrated with smart contracts. This ledger provides tracking information and multilateral collaboration between participants in the supply chain.

3 Supply chain network design

The supply chain network consists of suppliers, manufacturers, retailers, damaged points, and end-users. The main aim of this network design is to minimize the destination cost and reduce the number of undamaged items during the transport of the product from the manufacturer to the end-user. To minimize the distance and traveling cost we used a Bi-objective mathematical model. The parameter list and variable list mentioned below.

Variables:

- d:

-

Damage location (d € D)

- e:

-

end user location (e € E)

- m:

-

manufacture location (m € M)

- p:

-

product/item (p € P)

- s:

-

suppliers (s € S)

- t:

-

time period (t € T)

- j:

-

damage products (j € J)

Parameters:

- Njde:

-

Number of damaged products j, transfers from damaged location d to end-user e.

- N’dpmt:

-

The demand of damaged location d for product p from manufacturer m during time- period t.

- Fde:

-

Distance from damaged location d to end-user e.

- F’ms:

-

Distance from manufacturer m to supplier s.

- F”md:

-

Distance from manufacturer m to damage location d.

- PCpsmt:

-

purchase cost of product p from supplier s for manufacturer m during time- period t.

- TCpsmt:

-

Transport cost of product p from the supplier s to manufacturer m during time t.

- TC’pmdt:

-

Transport cost of product p from manufacturer m to damaged location d during time-period t.

- MCpmt:

-

Maintenance cost of product p in manufacturer during time-period t.

- TTpmt:

-

Time required for the demand of product p, in manufacturer m during time t.

- TT’pmt:

-

Time required for receiving product p, in manufacturer m during time t.

- DC pmt:

-

Delay cost of order product p from manufacturer m during time t.

- Spm:

-

Space needed for product p, during manufacturing m.

- S’pm:

-

Available space for product p, at manufacturer m side.

- LTpmdt:

-

Reaming lifetime of product p sends from manufacturer m to damage location d during time-period t.

- LT’psmt:

-

Reaming lifetime of product p, send from supplier s to manufacturer m during the time- period t.

- QOpmst:

-

Quantity of product p, ordered by manufacturer m from supplier s during time- period t.

- QO’pdmt:

-

Quantity of product p, ordered by damaged location d from manufacturer m during time-period t.

- QO”pmt:

-

Required quantity of product p, in manufacturer m during time-period t.

- QSpsmt:

-

Total Quantity of products p sends from supplier s to manufacturer m during time-period t.

- QS’pmdt:

-

Total Quantity of products p sends from manufacturer m to damage location d during time-period t.

- LMmpt:

-

Listing the manufacturer m for product p during time-period t.

- STpt:

-

Shortage time-period t of product p

- TTmp:

-

Summation of shortage time and available time of product p.

- L (Max)pmt:

-

Maximum listing of product p in manufacturer m during time-period t.

The above Eqs. (1–6) represent how the model would work. Equation (1) provides the relationship between the maximum listing of product p in manufacturer m and Quantity of product p, ordered by damaged location d from manufacturer m during time-period t. The relationship between delay cost of order product p from manufacturer m and quantity of product p, ordered by damaged location d from manufacturer m during time-period t are explained in the Eq. (2). Equation (3) provides information about the maximum listing of product p in manufacturer m during time-period t. The above Eq. (4) provides information about the quantity of product p, ordered by damaged location d, and the Delay cost of order product p from manufacturer m during time t. Equation (5) provides the Delay cost of ordering product p from manufacturer m and the time required for the demand of product p, in manufacturer m during time t. The above Eq. (6) provides the delay cost of order product p from manufacturer m during time t. In this approach to calculate the traceability of the product during the supply chain network, we consider the remaining time of the product. The remaining time of e product is used to maximize the number of products transferred from the supplier to the manufacturer and damage locations. It’s used to maximize the number of good condition products transferred from supplier to manufacturer and finally to damage locations.

To calculate the product lifetime exponential function, we consider the remaining lifetime of a product as input based on that we calculate the number of good conditioned products transferred within the level. Equation 7 represents the maximum number of undamaged products received by the manufacturer from the supplier.

Product maximum lifetime exponential function=

Where \( 1-{e}^{-{LT}_{psmt}^{\prime }} \) provides the product p while transferring the products between supplier s to manufacturer m during time-period t, and \( {e}^{-{LT}_{pmdt}} \) provides undamaged products reaching manufacturer.

3.1 Minimize the channel total cost (MinTC)

Equation 8 describes calculating the minimum supply chain total cost (MinTC) function we use two classes. Class 1 consists of the distance between the end-user and the damaged location. This cost is represented with ∝. the class two consists of transportation cost, maintenance cost, & purchase cost. Where ∝ represents the impact factor that satisfies the demand for damaged products.

4 Proposed novel approach for integrated Iot with blockchain in health supply chain (Naibhsc) approach

Blockchain provides decentralized, reliable, and secure network through which we can transfer health care products between manufacturer and customer through an SCM system. Smart contracts play a very curtail role in securely exchanging data between both parties. Blockchain and smart contracts allow for reducing the operational cost, minimizing the intermediate interactions, reducing the human interaction, and improving the self-execution of data stored in the blockchain. In the HSCM system using blockchain for providing tracking and effective tracing and monitoring of the products, we introduce the NAIBHSC approach. Figure 3 describes the architecture of our proposed NAIBHSC approach.

This approach consists of the front end, back end, and various sensors. The front end consists of various user interface devices like computers, and mobile devices. The backend consists of an Ethereum blockchain network. During transport from manufacturer to end-user, in this approach, we use various IoT devices like sensors, activators, and other devices, which are useful for Shipment tracking, temperature control, carrier identification, rapid delivery by continuous monitoring and route adjustments, delivery receipts and payments, and vehicle verification, and protecting the health-related products during transport and control the damages. IoT devices are intelligently connected in this technique, and real-time monitoring and tracking of these devices are possible. IoT joins these disparate things together via embedded sensors, actuators, and other devices to collect and transmit real-time data on network activity. The NAIBHSC architecture composed of different components those are:

-

Ethereum blockchain network: it’s open access and data-friendly services to everyone. In NAIBHSC architecture ethereum blockchain is useful for verifying front-end registered data. Smart contracts are running in an ethereum blockchain virtual machine. In blockchain networks, smart contracts are used to verify the data.

-

Smart contracts: It defines different operations that allow access control systems. The end users interrelate with the smart contract system by using the REST API (RESTful Application Programming Interface) and JSON (JavaScript Object Notation). In smart contracts, the system has to identify users’ requests, authenticate user requests, and provide the data access permissions for requested users through the messages or transactions. In this approach, smart contracts act as major software, through these different users access all operations in the blockchain network. Smart contracts provide automated recording and storing of events that are accessible to all participants in the network.

-

HTTP Server: A HyperText Transfer Protocol (HTTP) server is used to process various requests, and exchange information on the World Wide Web (WWW). This approach provides the interface between the front end and back end. The key purpose of an HTTP server is to store, process, and deliver web pages to clients.

-

Database: in this approach, we are using the PostgreSQL2 database for storing sensitive data, and user information.

-

IoT Devices: In medical logistic IoT devices plays a very crucial role during transport the products between the manufacturer and the end-user. IoT is a network of physical devices or things that are fixed with software, electronics devices, networks, various sensors, QR codes, RFID tags, and barcode systems that are allowed to collect and exchange data. In this Architecture, we use different sensors and activators during the logistic process. The sensor devices have sensing and identification capability which allows communication product temperature levels, pressure levels, voltage levels, sound levels, detecting light and longitude, and latitude position based on GPS. The data collected from the sensors can be stored, analyzed, and provided for decision-making to the various stack holders throughout the health supply chain. Sensor devices sense the environment, and then control signals are generated for the actuators. An actuator is a machine that controls the system environment. Based on the control signal generated by the sensors, the activator performs related actions. In this approach sensor devices sense the product environment and send the status to the blockchain network. In a blockchain network, smart contracts verify the sensor reports and verify reports stored in the form of URLs in the database. Before shipment, the sender packs the products associated with the MAC address of sensor devices and a QR code for tracking and tracing the product. The server stores the product details and broadcasts those details to the blockchain network. Using API both sender and receiver receive the status of the product during the transport of medical products. By using the tracking facility both sender and end-users know the current status of products during the shipment process. The client monitors the healthcare devices, analysis the status level, and perform tracking and tracing of product using QR code. The sensor devices store the recorded data in those devices every ten minutes because the sensor devices have very less memory capacity. After receiving the product client download all the sensor device information and send it to the smart contract. Smart contracts verify the sensor’s reading if any modifications have happened during the shipment of medical products. During shipment, if any environmental changes are identified by sensors related information is immediately noticed to both product owner and consumers. Based on users’ instructions activators performs related action in that environment.

4.1 Advantages of the proposed approach

NAIBHSC offers many advantages throughout the healthcare supply chain management system. The major advantages are:

-

Authentication and quality assurance: The use of blockchain technology allows for the effective tracking of goods from a store to a specific manufacturer or maker. Because each batch of items is equipped with a tag that effectively monitors the location of the commodities and interactions between supply chain actors, the data is highly reliable and credible.

-

Product tracking and tracing: Blockchain-based HSCM system offers a product tracking system that helps to trace the products from the manufacturer to end-users [18]. Blockchain maintains the chain of records that covers the information about manufacturers, drug authorities, distributors, and end-users [19, 37]. Product tracking and tracing help to provide confidence among various customers about the product’s authentication source, and tamperproof of the product between the manufacturer and customer [43].

-

Fight against counterfeit drugs: Blockchain provides distributed decentralized immutable data ledger facility. Blockchain technology does not depend upon third-party people for verifying products during transfer between the manufacturer and customer [30]. Once information is entered into the blockchain, it’s very difficult to alter/damage unauthorized users. Blockchain provides a proof of work concept by which only authorized users can transfer ownership to other persons. If any attacks occurred, we can easily identify the counterfeit product and easily remove it from the supply chain [25].

-

Provide transparency and security: The existing supply chain approaches use centralized data accessing, and also depend on third-party people for providing security and trust [3]. The data owners have no control over/her data, and they do know the information about participants involved in the SC during the transfer of the products. Blockchain provides data transparency, information about participants, decentralized data access, reliability, security, and trust throughout the supply chain [6].

-

Real-Time Information provider: Integrating IoT with Blockchain technology provides real-time information sharing between all parties involved in the transaction. The participants can easily access product information at any time in a transparent manner.

-

Fault Tolerance: One of the advantages of combining Blockchain and IoT is the possibility to achieve reliability through suitable fault tolerance methods. The consensus process in Blockchain is a fault-tolerance method that stops fraudulent nodes from writing erroneous data. Furthermore, every node in the network has a similar copy of the ledger, ensuring that all transactions are current.

-

Improving freight and delivery services: Smart contracts, which use data from the blockchain to verify when contractual obligations are completed and when payments can be given, can make functions like invoicing, payments, and physical transportation of products more cost-effective, auditable, and automated. The distributed ledger can help eliminate errors, speed up deliveries, and detect fraud [37].

-

Billing and payment automation: Transporting and delivering cargo from one location to another creates a supply chain with various entities and interactions. Billing and payment are the most complex and time-consuming transactions, and they can lead to manipulation, fraud, and errors. Blockchain can automate the invoicing and payment process, ensuring accuracy and accurate computations, eliminating the need for paperwork, ensuring transaction compliance, and speeding up the overall process.

5 Implementation

In this approach, we used the Ethereum blockchain platform for the automatic sharing the information between different users’ nodes. In this approach, we also use various features such as web3j, JSON-RPC, and Infura from the Ethereum blockchain. In this approach we used Solidity language for writing smart contracts; to perform compilation and testing we are using Remix IDE. This approach is for detecting various vulnerabilities and improving security levels using the SmartCheck tool. The below Table 1 provides Development environment of the proposed system.

In the above algorithm 1 describe the creation of the smart contract to deliver the product at the manufacturer’s end. By creating smart contracts, we can easily make invoicing, payments, and physical product shipping more cost-effective, auditable, and automated. It takes input as product Name, product Price, num. of Boxes, each box Price, IPFS hash value, Caller, Owner-ID and produces the results declaring that the Product has been manufactured and the Product image has been uploaded to the IPFS server.

The above algorithm 2 describes the granting product sale. After receiving the request from the customer manufacturer develop the product and make the product for sale.

The above algorithm 3 describes buying the product by the customer. In this process take the input as owner-ID, Buyer-id, Seller-id, Amount, and production cost of the Product to the seller. Update owner-ID by replacing it with the seller Ethereum address and finally produce the results declaring that the Product has been sold. Table 2 presents various participants in the blockchain network and their unique Ethereum addresses. During the transaction process based on this address, smart contracts verify the authenticity of the participants in the blockchain network.

5.1 Registration of product owner

In this phase, each manufacturer registers with our system. During the registration process, they must submit their product details and company details. If the manufacturer having own company, then only a registration process is allowed (Figs. 4, 5, 6 and 7).

5.2 Registration

In this phase, the manufacturer registers their products by providing product name, cost, product specifications, and provide product description.

5.3 Tracking

In this phase, both manufacturer and customer track the product’s longitude and latitude details by using the tracking ID provided by the manufacturer before the shipment process. Based on this tracking ID the customers know the current location of the product.

5.4 Transfer

In this phase, both parties agree on the smart contracts and transfer the amount from the customer account to the manufacturer account with the product Id.

6 Comparisons and result analysis

In this section, we provide a comparison between existing non-blockchain-based approaches, with our proposed approach with different parameters, and also perform a comparison with the existing blockchain-based approach with our proposed approach. Conduct various result analyses and performance analyses with different parameters.

6.1 Comparison non-blockchain approach with NAIBHSC approach

Table 3 describes the difference between existing non-blockchain-based approaches for health supply chain management systems with our proposed NAIBHSC approach. Our Approach provides a data decentralization facility to avoid single entity problems, modification, or damage attackers from attackers. Compare to existing approaches our proposed approach provides flexibility, integrity, security, transparency, and trust. The existing approaches also have to track and trace facilities but our approach uses various IoT devices to provide effective tracking and tracing facilities compare to other approaches.

6.2 Comparison blockchain-based approaches with NAIBHSC approach

Table 4 describes the comparison between the existing blockchain-based approaches with our proposed approach. In this comparison, we mainly focus on various platforms used to develop the approaches, mode of operations, type of currency, and off-chain data storage (a large amount of non-transactional data that is to be stored efficiently on the blockchain or requires the ability to be updated or removed is called as off-chain data.), and programming languages used to develop the approaches.

6.3 Performance evaluation

In this approach to evaluate performance, we used the Caliper tool. Caliper is an open-source blockchain-based performance benchmark framework. This tool is useful for evaluating various performance metrics like resource utilization, Response time, latency time, success rate, and throughput. Caliper framework tests various use cases and provides performance results. In this approach, we mainly concentrate on transaction response time and Transaction latency. Response time is the total time required to take the request and get a response from the blockchain network. Latency time is the total transaction time required across the network. The entire time comprises the time between submission and the network’s available result.

Figure 8 represents the response time of three different groups of users in the network. The below diagram investigated Transaction Per Second (TPS). In this comparison, we consider 100 users group in the first round, in the second round we form 300 users as a group, and in the last round, and 500 users group is taken to evaluate the performance. However, as the number of users grows, the TPS grows as well. Figure 8 shows the average TPS for a group of 300 users is 70, while for a group of 500 users, it is 100. With an elapsed time of 100 seconds, the average TPS is 115.

Figure 9 depicts the average; minimum, maximum, and percentile latency for the proposed systems invoke process and query function. In this approach for calculating the latency, we use 3 different range (100,300,500) user groups. The experimental results show average latency time for 100 group users has 145 milliseconds, 300 users have 162 milliseconds, and 500 users group has 403 milliseconds. The minimum latency for 100 group users has 100 milliseconds, 300 users have 103 milliseconds, and 500 users group has 110 milliseconds. The maximum latency for a group of 100, 300, and 500 users is 218 milliseconds, 434 milliseconds, and 1102 milliseconds, respectively.

The comparisons and experimental results show that the integration of IoT and blockchain (NAIBHSC) approach gives better results in terms of improving security, privacy, trust, and transparency, tracing the product, improving the response time, reducing the latency time, and improving the performance.

7 Conclusion & feature enhancement

Today’s Supply chain in the healthcare sector faces many problems like security, transparency, tampering with medical products, counterfeit drugs, more paperwork, high cost, and more time-consuming process while transporting medical equipment from manufacture to end-users. To overcome these problems, we introduce Novel Approach for Integrated IoT (Internet of Things) With Blockchain in Health Supply Chain (NAIBHSC) approach. In this approach, we integrate Blockchain technology with IoT for improving health supply chain management. This proposed approach provides decentralized tracking and tracing of the medical product, avoids counterfeit drugs, and provides the status of the products during the shipment process between manufacturers to end-user. In this approach to provide security, transparency, and trust we developed smart contracts by using a solidity programming language in combination with public permission ethereum blockchain technology. By using this approach we can reduce the errors and eliminate the frauds, reduce the delays, minimize human interaction, improve efficiency and accuracy, improve inventory management and minimize the cost. In this approach, we used a Bi-objective mathematical model to minimize the destination cost and reduce the number of undamaged items during the transport of the product from manufacture to end-user. The comparisons and experimental results show that our proposed NAIBHSC approach gives better results in terms of improving response time, reducing the latency time, and increasing the performance. Finally, this approach eliminates the challenges faced by the health supply chain management system, easily identifies issues that occurred in the supply chain, and increases sustainability. In the feature work, we are going to conduct various testing on different parameters like resource utilization, success rate, throughput, and network size to check the performance and feasibility in the real-time environment.

References

Abdel-Bassett M, Manogaranb G, Mohamed M (2018) Internet of things (IoT) and its impact on supply chain: a framework for building smart, secure and efficient systems. Future Gener Comput Syst. https://doi.org/10.1016/j.future.2018.04.051

Agbo CC, Mahmoud QH, Eklund JM (2019) Blockchain technology in healthcare: a systematic review. Healthcare 7:56. https://doi.org/10.3390/healthcare7020056

Al Huraimel K, Jenkins R (2020) Smart track. Available: https://smart.track.ae/. Accessed 26 May 2020

Alizadeh M, Makui A, Mahdi Paydar M (2019) Forward and reverse supply chain network design for consumer medical supplies considering biological risk. Comput Ind Eng 140:106229. https://doi.org/10.1016/j.cie.2019.106229

Boceky T, Rodrigues BB, Strasser T, Stiller B (2017) Blockchains everywhere - A use-case of blockchains in the pharma supply-chain. 2017 IFIP/IEEE International Symposium on Integrated Network Management (IM2017): Experience Session - Full Paper

Bryatov SR, Borodinov AA (2019) Blockchain technology in the pharmaceutical supply chain: researching a business model based on Hyperledger Fabric. V International Conference on "Information Technology and Nanotechnology" (ITNT-2019)

Chang SE, Chen Y-C, Lu M-F (2019) Supply chain re-engineering using blockchain technology: a case of smart contract-based tracking process. Technol Forecast Soc Change 144(2019):1–11

Costa C, Antonucci F, Pallottino F, Aguzzi J, Sarriá D, Menesatti P (2013) A review on agrifood supply chain traceability using RFID technology. Food Bioprocess Technol 6:353–366. https://doi.org/10.1007/s11947-012-0958-7

Datta S et al. (2021) BSSFFS: blockchain-based sybil-secured smart forest fire surveillance. J Ambient Intell Human Comput. https://doi.org/10.1007/s12652-021-03591-1

Ding B (2018) Pharma Industry 4.0: literature review and research opportunities in sustainable pharmaceutical supply chains. Process Saf Environ Prot. https://doi.org/10.1016/j.psep.2018.06.031

Dwivedi SK, Amin R, Vollala S (2020) Blockchain based secured information sharing protocol in supply chain management system with key distribution mechanism. J Inf Secur Appl 54:102554

Faulkner C (2020) What is NFC? Everything you need to know. Available: https://techradar.com. Accessed 3 Jun 2020

Fekih RB, Lahami M (2020) Application of blockchain technology in healthcare: a comprehensive study. ICOST 2020, LNCS 12157, pp 268–276, 2020

Fernando E, Surjandy M (2019) Success factor of implementation blockchain technology in pharmaceutical industry: a literature review. Proc of 2019 6th Int Conf on Information Tech, Computer, and Electrical Engineering (ICITACEE), Sep 26–27, 2019, Semarang, Indonesia

Gan C, Saini A, Zhu Q, Xiang Y, Zhang Z (2020) Blockchain-based access control scheme with an incentive mechanism for eHealth systems: patient as supervisor. Multimed Tools Appl 1–17. https://doi.org/10.1007/s11042-020-09322-6

Geneva: World Health Organization (2017) A study on the public health and socioeconomic impact of substandard and falsified medical products. License: CC BY-NC-SA 3.0 IGO, ISBN 978-92-4-151343-2

Goodarzian F, Taleizadeh AA, Ghasemi P, Abraham A (2021) An integrated sustainable medical supply chain network during COVID-19. Eng Appl Artif Intell 100:104188

Huang Y, Wu J, Long C (2018) Drugledger: a practical blockchain system for drug traceability and regulation. 2018 IEEE Confs on internet of things. https://doi.org/10.1016/j.psep.2018.06.031

Humayun M, Jhanjhi N, Hamid B, Ahmed G (2020) Emerging smart logistics and transportation using IoT and blockchain. IEEE Internet Things Mag 3(2):58–62. https://doi.org/10.1109/IOTM.0001.1900097

IsraaAbu-elezz I, Hassan A, Nazeemudeen A, Househ M, Abd-Alrazaq A (2020) The benefits and threats of blockchain technology in healthcare: a scoping review. Int J Med Inf 104246. https://doi.org/10.1016/j.ijmedinf.2020.104246

Jamil F, Hang L, Kim KH, Kim DH (2019) A novel medical blockchain model for drug supply chain integrity management in a smart hospital. Electronics 8:505. https://doi.org/10.3390/electronics8050505

Jayaraman R et al (2019) Improving opportunities in healthcare supply chain processes via the internet of things and blockchain technology. Int J Heal Inf Syst Informatics 14:49–65

Khatoon A (2020) A blockchain-based smart contract system for healthcare management. Electronics 9:94. https://doi.org/10.3390/electronics9010094

Khezr S, Moniruzzaman M, Yassine A, Benlamri R (2019) Blockchain technology in healthcare: a comprehensive review and directions for future research. Appl Sci 9:1736. https://doi.org/10.3390/app9091736

Koh L, Dolgui A, Sarkis J (2020) Blockchain in transport and logistics – paradigms and transitions. Int J Prod Res 58(7):2054–2062. https://doi.org/10.1080/00207543.2020.1736428

Kuandee W, Nilsook P, Wannapiroon P (2019) Asset supply chain management system-based IoT technology for higher education institutions. Int J Online Biomed Eng 15:4–20

Kumar SG, Prince S, Shankar BM (2021) Smart tracking and monitoring in supply chain systems using RFID and BLE. 2021 3rd International Conference on Signal Processing and Communication (ICPSC), pp 757–760. https://doi.org/10.1109/ICSPC51351.2021.9451700

Kumar A et al (2019) Authentication and privacy preservation in IoT based forest fire detection by using blockchain - a review, In 4th International Conference on Internet of Things and Connected Technologies (ICIoTCT), pp 133–143. https://doi.org/10.1007/978-3-030-39875-0_14

Kuo T-T, Kim H-E, Ohno-Machado L (2017) Blockchain distributed ledger technologies for biomedical and health care applications. J Am Med Inform Assoc 24(6):1211–1220

Manavalan E, Jayakrishna K (2018) A review of internet of things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput Ind Eng. https://doi.org/10.1016/j.cie.2018.11.030

McGhin T, Choo K-KR, Liu CZ, He D (2019) Blockchain in healthcare applications: Research challenges and opportunities. Journal of Network and Computer Applications 135(2019):62–75

Musamih A, Salah K, Jayaraman R, Arshad J, Debe M, Al-Hammadi Y, Ellaham S (2021) A blockchain-based approach for drug traceability in healthcare supply chain. IEEE Access

Panda SK, Satapathy SC (2021) Drug traceability and transparency in the medical supply chain using blockchain for easing the process and creating trust between stakeholders and consumers. Pers Ubiquit Comput. https://doi.org/10.1007/s00779-021-01588-3

Panda SK, Satapathy SC (2021) An investigation into smart contract deployment on ethereum platform using Web3.js and solidity using blockchain. In: Bhateja V, Satapathy SC, Travieso-González CM, Aradhya VNM (eds), Data engineering and intelligent computing. Advances in intelligent systems and computing, vol 1. Springer, Singapore. https://doi.org/10.1007/978-981-16-0171-2_52

Raj R, Rai N, Agarwal S (2019) Anticounterfeiting in pharmaceutical supply chain by establishing proof of ownership. 2019 IEEE Region 10 Conference (TENCON 2019)

Singh RK, Kumar P (2020) Measuring the flexibility index for a supply chain using graph theory matrix approach. J Glob Oper Strateg Sourc 13(1)

Singh AP, Pradhan NR, Luhach AK, Agnihotri S, Jhanjhi NZ, Verma S, Kavita, Ghosh U, Roy DS (2021) A novel patient-centric architectural framework for Blockchain-enabled healthcare applications. IEEE Trans Ind Inform 17(8):5779–5789. https://doi.org/10.1109/TII.2020.3037889

Singh B, Sharma KP, Sharma N (2020) Blockchain applications, opportunities, challenges, and risks: a survey. Proc Int Conf Innov Comput Commun (ICICC). https://doi.org/10.2139/ssrn.3565930

Sinha S (2021) D. BESDDFFS: blockchain and edgedrone based secured data delivery for forest fire surveillance datta. Peer-to-Peer Netw Appl 14:3688–3717. https://doi.org/10.1007/s12083-021-01187-2

Tijan E, Aksentijevi S, Ivani K, Jardas M (2019) Blockchain technology implementation in logistics. Sustainability 11:1185. https://doi.org/10.3390/su11041185

Tseng J-H, Liao Y-C, Chong B, Liao S-w (2018) Governance on the drug supply chain via gcoin blockchain. Int J Environ Res Public Health 15(6):1055. https://doi.org/10.3390/ijerph15061055

Xu Q, Jin C, Rasid MFBM, Veeravalli B, Aung KMM (2018) Blockchain-based decentralized content trust for docker images. Multimed Tools Appl 77(14):18223–18248. https://doi.org/10.1007/s11042-017-5224-6

Yli-Huumo J, Ko D, Choi S, Park S, Smolander K (2016) Where is current research on Blockchain technology? A systematic review. PLoS One 11(10):e0163477. https://doi.org/10.1371/journal.pone.0163477

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The dataset generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nanda, S.K., Panda, S.K. & Dash, M. Medical supply chain integrated with blockchain and IoT to track the logistics of medical products. Multimed Tools Appl 82, 32917–32939 (2023). https://doi.org/10.1007/s11042-023-14846-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11042-023-14846-8