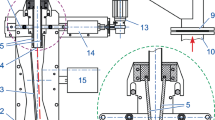

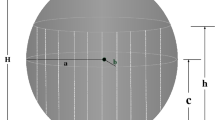

An experimental method is presented for determining the minimum time interval for filling a storage tank with working fluid during reproduction of the units of mass and volume of fluid in a flow and the mass and volume flow rates of the liquid by a calibration unit with a weighing device. Experiments are done over a wide range of mass flow rates 11.10–83.26 kg/s (40–300 t/h) with repeated static weighing of the working fluid. The flow switch is made with a fixed geometry of the flow-through part of the nozzle cutoff, which is typical of a large number of calibration units with weighing devices in use in our country. Plots of the experimental data on the mass flow rate as a function of the time to fill the storage tank are the basis for optimizing the process of reproducing the units of mass and volume of fluid in a flow and the mass and volume flow rates of a liquid by calibration units with weighing devices. These graphs yield recommendations for a justified choice of minimum time interval for filling the storage tank with working fluid within the range of mass flow rate being studied. The optimization has been tested and can be extended to calibration units with weighing devices from various manufacturers with individual designs and operating parameters.

Similar content being viewed by others

References

N. I. Kosach, Sist. Obrab. Inform., No. 6 (64), 47–50 (2007).

I. V. Marfenko, Y. T. Yeh, and J. D. Wright, 6th Int. Symp. for Fluid Flow, Queretaro, Mexico, May 16–18, 2006, https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=831030, acc. Jan. 2, 2020.

T. Shimada, S. Oda, Y. Terao, and M. Takamoto, Flow Meas. Instrum., 14, 88–96 (2003), DOI: https://doi.org/10.1016/S0955-5986(03)00016-5.

R. Engel and H. J. Baade, 8th Int. Symp. on Fluid Flow Measurement, Colorado Springs, CO, USA, June 20–22, 2012, https://www.researchgate.net/publication/260596798, acc. Jan 2, 2020.

R. A. Korneev. A. R. Tukhvatullin, V. A. Fafurin, and A. V. Shchelchkov, “Estimating the effect of a flow switch on the metrological characteristics of calibration units for the units of mass and volume of fl ows in liquids, and the mass and volume flow rates of liquids,” Izmer. Tekhn., No. 4. 14–19 (2019), DOI https://doi.org/10.32446/0368-1025it.2019-4-42-47.

R. A. Korneev. A. R. Tukhvatullin, V. A. Fafurin, et al., “Evaluation of standard measurement caused by a flow switch in the uncertainty budget of a standard,” Zakonodat. Prikl. Metrol., No. 1, pp. 42–47 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izmeritel’naya Tekhnika, No. 2, pp. 60–64, February, 2020.

Rights and permissions

About this article

Cite this article

Korneev, R.A., Tukhvatullin, A.R., Fafurin, V.A. et al. Optimization of the Process of Reproducing the Units of Mass and Volume of Liquid in Flows, and Mass and Volume Flow Rates of Liquid for Calibration Units with Weighing Devices. Meas Tech 63, 140–144 (2020). https://doi.org/10.1007/s11018-020-01763-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11018-020-01763-7