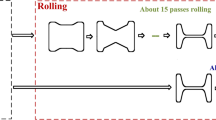

Construction and commissioning of a network of mini-mills of various maximum production volumes requires installation of equipment. Several plants have developed mills in which continuous-reduction stands have been replaced by three-high stands. Despite prior experience in using continuous-cast billets for production of a variety of rolled shapes in modern continuous mills, use of this approach in shape mills with three-high reduction stands requires an technical feasibility assessment of the new forming modes and pass designs used for these modes. Comparative analysis indicated that the newly developed billet forming modes and pass designs did not fully achieve the requisite technical feasibility. The stress-strain behavior in the early passes facilitates not only formation of end cracks, but also increases the likelihood of discontinuity defects in the metal over the entire free surface of the billet not in contact with the bottom or corners of the pass due to development of tensile stresses. Absence of reduction in the initial box passes during rolling of continuous-cast billets therefore will lead to rhombicity defects. Using excessively high reductions in individual passes makes clamping of the process cross section less stable, increases the likelihood of overfilling the pass, and increases the peak rolling load in certain passes Collectively this suggests that these process characteristics indicate that a better-validated approach is needed for determination of continuous-cast billet rolling schedules for three-high reduction stands.

Similar content being viewed by others

References

A. Smirnov, E. Smirnov, V. Sklyar, V. Belevitin, and R. Pivovarov, “Producing structural-steel bar from continuous-cast billet,” Steel in Translation, 48, 233–239 (2018).

A. B. Steblov, A. V. Nalivaiko, and O. N. Tulupov, “Analysis of the level of the technology used to make reinforcement steel of class A500S at the casting and rolling plant in Yartsevo,” Metallurgist, 54, No. 7–8, 548–555 (2010); English translation:Metallurg, No. 8, 68–84 (2008).

E. N. Smirnov and V. V. Shcherbachev, “Production of ship sections from continuous casting billets,” Stal,’8, 102–106 (2002).

S. G. Grishchenko, D. V. Stalinskiy, A. S. Rudyuk, and V. S. Medvedev, “Metallurgical mini enterprises for the production of complex rolled products in small batches,” Stal,’ No. 9, 53–56 (2008).

M. V. Potapova and M. G. Potapov, “The trends for metallurgical mini-mills development in the Russian Federation,” Modern Science, No. 10, 11–15 (2017).

Tula Metal Rolling Plant (TMPZ); http://tulampz.ru/ (date retrieved: 01.09.2019)

Volga Electrometallurgical Plant LLC; www.vemz.org (date retrieved: 01 September 2019)

E. N. Smirnov, A. N. Smirnov, V. A. Sklyar, V. A. Belevitin, S. P. Eron’ko, and R. E. Pivovarov, “Effects of decreasing the initial rolling temperature in three-high roughing stands,” Steel in Translation, 48, No. 6, 381–387 (2018).

B. M. Ilyukovich, N. E. Nehaev, and S. E. Merkur’ev, Roll and Pass Design. A Handbook in 6 Volumes. Vol. 1, RIA Dnepro-VAL, Dnepropetrovsk (2002).

A. A. Korolev, Mechanical Equipment for Rolling and Pipe/Tube Rolling Shops [in Russian], Metallurgiya, Moscow (1987).

A. P. Chekmarev and Yu. Sh. Maizlin, Automated Delivery Guides for Rolling Mills [in Russian], Izd-vo Akademii Nauk USSR, Kiev (1952).

Yu. M. Chizhikov, Rollability of Steel and Alloys [in Russian], Metallurgizdat, Moscow (1961).

A. P. Grudev, Theory of Rolling, Metallurgiya, Moscow (1988).

M. Ya. Brovman, “Porosity reduction during metal forming,” Izv. VUZov. Chernaya Metallurgiya, No. 5, 35–37 (2001).

E. N. Smirnov, A. N. Smirnov, V. A. Sklyar, et al., “Influence of the Reduction in the First Matched Groove Pair of a Three-High Stand on Billet Damage,” Steel in Translation, 49, 332–338 (2019); English translation:Stal,’ No. 5, 21–27 (2019).

E. N. Smirnov, V. A. Sklyar, A. N. Smirnov, et al., “A study of the effect of temperature conditions in laminated continuous-cast shaped billets on end cracking during rolling,” Izv. VUZov. Chernaya Metallurgiya, 62, No. 7, 539–547 (2019).

CVS Steely Solutions; http://www.cvs.com.tr/ru/index.php/ (date retrieved: 01 September 2019)

A. A. Minaev, A. G. Nosanev, E. N. Smirnov, et al., “Unit for accelerated cooling of reinforcement bars in the line of a 330 mill after deformation,” Metallurgist, No. 1, p. 32 (1990).

A. N. Smirnov, A. S. Khobta, A. I. Serov, et al., “Casting of steel from the tundish of a continuous caster with a sliding gate,” Russian Metallurgy (Metally), No. 12, 1–5 (2012).

Germaksan-Yolbulan Demir Industry and Trade Inc. [Electronic resource]; https://germaksan.com.tr/ (Date retrieved: 01 September 2019)

A. P. Chekmarev, M. S. Mut’ev, V. P. Mashkovets, Roll Pass Design [in Russian], Metallurgiya, Moscow (1981).

V. K. Smirnov, V. L. Shilov, Yu. M. Inatovich, Roll Pass Design [in Russian], Teplotekhnik, Moscow (2010).

A. A. Minaev, E. N. Smirnov, M. V. Grigor’ev, et al., “Rolling of continuous-cast billet in shape-mill reduction stands,” in: Collected Papers from the Scientific and Technical Conference on Machine Building and the 21st Century Technology Environment (Sevastopol, 8–14 September 2003), DonNTU, Donetsk, Vol. 2, (2003), pp. 257–262.

A. A. Minaev, E. N. Smirnov, V. B. Shum, et al., “Modeling deformation of a continuous-cast billet in matched box passes with a novel design,” Metallurgicheskie Protsessy i Oborudovanie, No. 2 (28), 32–42 (2012).

K. A. Zav’yalov, “Metal torsion index and the mathematical description of torsion,” Modelirovanie i Razvitie Processov OMD, No. 1, 207–211 (2011).

V. M. Klimenko and A. M. Onishchenko, Kinematics and Dynamics of Rolling Processes [in Russian], Metallurgiya, Moscow (1984).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated from Metallurg, Vol. 63, No. 12, pp. 51–57, December, 2019.

Rights and permissions

About this article

Cite this article

Smirnov, E.N., Smirnov, A.N., Sklyar, V.A. et al. Technical Feasibility Assessment for Roll Pass Designs in Three-High Shape-Mill Stands in Modern Mini-Mills. Metallurgist 63, 1294–1302 (2020). https://doi.org/10.1007/s11015-020-00951-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-00951-8