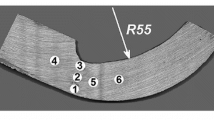

On the basis of analyzing 22 melts of high-strength steel (σ0.2 = 428–886 MPa) of different grades 3–25 mm thick produced within countries of the European Union by thermomechanical rolling technology, the effect of chemical composition and structure on a set of mechanical properties is studied. It is shown that yield strength of high-strength steels is due to titanium, niobium, and vanadium carbonitrides. The contribution of titanium to steel strength is greater than that of niobium by a factor of three, and by a factor of 16.5 for vanadium. An increase in steel yield strength above 750 MPa leads to its inclination towards an increase in impact strength anisotropy coefficient K a. In the concentration range 0.001–0.08 wt.% Ti, the value of K a = 1–2 is independent of Ti content, but increases sharply to K a = 3.8 with a Ti content in steel of 0.09 to 0.14 wt.% giving rise to a requirement for limiting Ti content to not more than 0.08 wt.%. A marked effect of Ti and Al concentration on high-strength steel impact strength is established with entirely ductile failure KCV max. According to x-ray-spectral analysis data, coarse (with a size of 2.2–2.8 μm) inclusions have a complex structure. During formation, inclusions contain up to 15–17 wt.% Al, and then an outer layer forms upon them having up to 29–42 wt.% Ti.

Similar content being viewed by others

Notes

This value was determined as the average ratio of impact strength in longitudinal specimens KCVlo to the impact strength of transverse specimens KCVt with identical test temperatures [2].

References

EN 10025-4:2004, Hot Rolled Products of Structural Steel. Part 4: Technical Delivery Conditions for Thermomechanical Rolled Weldable Fine Grain Structural Steels.

V. M. Goritskii, M. A. Lushkin, O. V. Goritskii, and G. R. Shneiderov, “Effect of structural factors on impact strength anisotropy for ferrite-pearlite rolled sheet steel,” Deform. Razrush. Mater., No. 8, 16–21 (2014).

R. Kisling and N. Lang, Nonmetallic Inclusions in Steel [Russian translation], Metallurgiya, Moscow (1968).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 5, pp. 49–55, May, 2016.

Rights and permissions

About this article

Cite this article

Goritskii, V.M., Shneiderov, G.R. & Guseva, I.A. Effect of Chemical Composition and Structure on Mechanical Properties of Low-Alloy Weldable Steels After Thermomechanical Treatment. Metallurgist 60, 511–518 (2016). https://doi.org/10.1007/s11015-016-0323-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0323-6