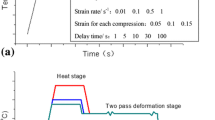

The meta-dynamic recrystallization behavior of SCM435 steel was studied on the MMS-200 thermal simulation machine through the double-pass compression experiment. The effects of the deformation temperature, the strain rate, and the initial austenite grain size on meta-dynamic recrystallization were analyzed. Based on the test result, the kinetics model of the meta-dynamic recrystallization of SCM435 steel was established, and the obtained activation energy was 242.3kJ/mol. The results showed that the meta-dynamic recrystallization fraction Xm of SCM435 steel increased as the deformation temperature and the deformation rate increased, decreased as the initial grain size increased, and increased as the time interval increased.

Similar content being viewed by others

References

A. M. Elwazri, P. Wanjara, and S. Yue, “Metadynamic and static recrystallization of hypereutectoid steel,” ISIJ Int., 43, No. 7: 1080–1088 (2003).

P. Uranga, A. I. Fernandez, B. Lopez, et al., “Transition between static and metadynamic recrystallization kinetics in coarse Nb microalloyed austenite,” Mater. Sci. Eng. A, 345, 319–327 (2003).

F. Chen, Z. S. Cui, and S. J. Chen, “Recrystallization of 30Cr2Ni4MoV ultra-super-critical rotor steel during hot deformation. Part Ш: Metadynamic recrystallization,” Mater. Sci. Eng. A, 540, 46–54 (2012).

Y. C. Lin, M. S. Chen, and J. Zhong, “Study of metadynamic recrystallization behaviors in a low alloy steel,” J. Mater. Proc. Technol., 209, 2477–2482 (2009).

S. Tatsuo, S. Takashi, O. Kenji, et al., “Statistical fatigue properties of SCM435 steel in ultra-long-life regime based on JSMS database on fatigue strength of metallic materials,” Int. J. Fatig., 28, 1486–1492 (2006).

W. Yue, X. J. Sun, C. B. Wang, et al., “A comparative study on the tribological behaviors of nitrided and sulfur-nitrided 35CrMo steel lubricated in PAO baseoil with MoDTC additive,” Tribol. Int., 44, 2029–2034 (2011).

D. Xu, M. Y. Zhu, Z. Y. Tang, et al., “Determination of the dynamic recrystallization kinetics model for SCM435 steel,” J. Wuhan Univ. Technol. Mater. Sci. Ed., 28, No. 4, 819–824 (2013).

K. Kanekoa and T. Oyamada, “A viscoplastic constitutive model with effect of aging,” Int. J. Plasticity, 16, 337–357 (2000).

Acknowledgments

The corresponding author gratefully acknowledges the help and support of the LMPSC laboratory of Northeastern University and Youth Academic Backbone Foundation of HeBei University of Engineering (No. 00060534).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Metallurg (in Russian), No. 10, pp. 30–33, October, 2015.

Rights and permissions

About this article

Cite this article

Xu, D., Zheng, B., Zhu, M. et al. Meta-Dynamic Recrystallization Behavior of SCM435 Steel. Metallurgist 59, 899–903 (2016). https://doi.org/10.1007/s11015-016-0190-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0190-1