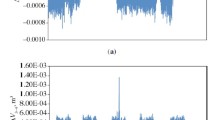

Results are presented from a wavelet analysis of fluctuations in the thickness of strip that was cold-rolled during vibration of the mill’s roll system. The vibrations were caused by a problem with the reduction gear in the main line of the mill. Results obtained by using the software Deform 2D to model the process of rolling with vibration are also presented.

Similar content being viewed by others

References

M. Markwort, “Diagnosis of vibrations of a rolling mill,” Chern. Metally, No. 8, 39–44 (2008).

I. P. Mazur, “Problems in the quality control of the surface during the production of flat-rolled products,” Stal, No. 4, 31–36 (2011).

E. A. Garber, I. S. Pavlov, I. A. Kozhevnikova, et al., “Eliminating surface defects on cold-rolled strip due to vibrations of the working stands,” ibid., 36–41.

Yang Xu and Tong Chao-nan Tong, “Coupling dynamic model and control of chatter in cold rolling,” J. Dyn. Syst., Measur., Control. Trans. ASME, 134, No. 4, 1–8 (2012).

N. M. Astafieva, “Wavelet analysis: basic theory and some applications,” Physics-Uspekhi, 39, No. 11, 1085–1108 (1996).

D. T. L. Lee and Akio Yamamoto, “Wavelet analysis: theory and applications,” Hewlett-Packard J., December, 44–54 (1994).

Tao Qian, Mang I. Vai, and Yuesheng Xu (eds.), Wavelet Analysis and Applications. Ser.: Applied and Numerical Harmonic Analysis, Birkhäuser Basel (2007), XIV, www.springer.com.birkhauser/mathematics/book/978-3-7643-7777-9.

K. Blatter, Wavelet Analysis. Principles of the Theory [Russian translation]. Ser.: Mir Matematiki, Tekhnosfera, Moscow (2006).

I. Ya. Novikov, V. Yu. Protasov, and M. A. Skopina, Wavelet Theory [in Russian], FIZMATLIT, Moscow (2005).

M. M. Skripalenko, D. A. Ashikhmin, M. N. Skripalenko, et al, “Use of the software Deform 2D to model the process of rolling with vibration of the top work roll,” Metallurg, No. 11, 60–62 (2012).

Yu. M. Mikhailov, Developing a Method of Diagnosing the Mechanisms of the Main Line of a Rolling Mill to Detect Problems That Affect the Accuracy of the Rolled Product: Auth. Abstr. Eng. Sci. Cand. Dissert., MISiS, Moscow (2008).

Ya. L. Solomonik, Yu. M. Mikhailov, M. N. Skripalenko, and D. A. Ashikhmin, “Diagnosing mechanisms in the main line of a rolling mill to detect problems that affect the accuracy of the rolled product,” Tekhnol. Legk. Splavov, No. 2, 101–106 (2009).

M. N. Skripalenko, M. M. Skripalenko, S. N. Bogdanov, et al., “Diagnostic modeling of rolling-mill equipment to improve the accuracy of the rolled product,” Proc. Sci.-Tech. Conf. Innovative Technologies in Metal-Shaping, NITU MISiS, Moscow (2011), pp. 248–249.

M. N. Skripalenko and D. A. Ashikhmin, “Diagnostic computer modeling of processes in rolled-product manufacture to create standards on the quality of metallic rolled products,” Proc. Int. Youth Conf. Computer Modeling of New Materials, NITU MISiS Moscow (2012), p. 60.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 7, pp. 45–50, July, 2013.

Rights and permissions

About this article

Cite this article

Skripalenko, M.N., Skripalenko, M.M., Ashikhmin, D.A. et al. Wavelet Analysis of Fluctuations in the Thickness of Cold-Rolled Strip. Metallurgist 57, 606–611 (2013). https://doi.org/10.1007/s11015-013-9777-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-013-9777-y