Abstract

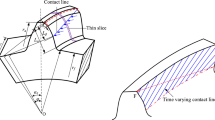

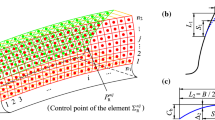

A “slice method” is adopted to calculate the time-varying mesh stiffness (TVMS) of helical gear pairs, where the tooth is divided into many individual sliced spur gears along the tooth width, and the TVMS of helical gear pairs is obtained by accumulating the TVMS of the sliced spur gear pairs. Based on the slice method, an improved analytical method (IAM) is proposed to calculate TVMS of the helical gear pairs. The proposed method is also verified by comparing TVMS obtained from IAM with that obtained from references and the finite element method. Based on the proposed IAM, the effects of the helix angle, gear width, modification coefficient and friction coefficient on mesh characteristics are also discussed. The results show that the total contact ratio of helical gear changes under different helix angles and gear tooth widths, and the fluctuation of mesh stiffness will reduce when the overlap contact ratio approaches an integer. Meanwhile, addendum modifications can not only change the total contact ratio but also affect the mean mesh stiffness of gear pairs. Furthermore, not only will the friction coefficients affect the mean mesh stiffness, and it can lead to an abrupt change of TVMS in double-teeth engagement region.

Similar content being viewed by others

Abbreviations

- a :

-

The center distance

- c, c t :

-

The tip clearance coefficient and the transverse tip clearance coefficient

- E, E e :

-

The Young’s modulus and the effective elastic modulus

- F :

-

The total meshing force

- \((F_{i}^{n} )_{j}\) :

-

The meshing force of the ith tooth pair of the nth gear slice at meshing position j

- (k n) j :

-

The mesh stiffness of the nth gear slice at meshing position j

- h a, h at :

-

The addendum coefficient and the transverse addendum coefficient

- k ai (i = 1, 2):

-

The axial compressive stiffness, subscripts 1 and 2 denote the driving and driven gears, respectively

- k bi (i = 1, 2):

-

The bending stiffness

- k fi (i = 1, 2):

-

The stiffness of fillet-foundation

- \((k_{{{\text{h}}i}}^{n} )_{j}\) :

-

Hertzian contact stiffness of the ith meshing tooth pair under nth gear slice at meshing position j

- k si (i = 1, 2):

-

The shear stiffness

- k ti (i = 1, 2):

-

The stiffness of tooth

- \((k_{\text{tooth}}^{n} )_{j}\) :

-

The total mesh stiffness of m meshing tooth pairs at meshing position j

- \(k_{\text{tooth}}^{i}\) :

-

The mesh stiffness of the ith tooth pair

- ΔK :

-

The difference between the minimum and the maximum

- K j :

-

The total mesh stiffness of the helical gear pairs at meshing position j

- K mean :

-

The mean stiffness in one meshing cycle

- l, L :

-

The tooth width of each thin slice and the tooth face width of the gear pair

- m :

-

The number of tooth pairs in meshing at the same time

- m n, m t :

-

The normal module and the transverse module of helical gear

- n, N :

-

The nth thin gear slice and the total slice number

- \((z_{i}^{n} )_{j}\) :

-

The z coordinate value of nth thin gear slice at meshing position j

- Z i (i = 1, 2):

-

The number of the teeth,

- r i , r ai , r bi (i = 1, 2):

-

The radii of the gear pitch circle, addendum circle, base circle,

- r inti (i = 1, 2):

-

Hub radius

- R :

-

The judge parameter in the effective elastic modulus theory

- α ai (i = 1, 2):

-

Pressure angle of the addendum circle

- (α n ) j :

-

The instantaneous pressure angle of nth slice at meshing position j

- α max, α min :

-

The maximum and the minimum pressure angle

- α 0, α t :

-

The pressure angle and the transverse pressure angle

- β, β b :

-

The helix angles of pitch circle and base circle

- γ :

-

The angular displacement of arbitrary point at the transition curve

- ε, ε α , ε β :

-

The total contact ratio, the transverse contact ratio and the overlap contact ratio

- η :

-

The dimensionless quantity value for the fluctuation of stiffness

- θ b1, θ b2 :

-

The half tooth angle on the base circle for the driving and driven gears, respectively

- λ i (i = 1, 2):

-

The fillet-foundation stiffness coefficient

- μ :

-

The friction coefficient

- ν :

-

The Poisson ratio

- τ :

-

The angular displacement of arbitrary point at the involute curve

- \((\tau_{ 1 ,i}^{n} )_{j}\) :

-

Operating pressure angle of the ith tooth pair of the nth gear slice of the driving gear at meshing position j

- τ C :

-

The meshing angle at the position of the involute starting point

- φ min :

-

The minimum rolling angle of driving gear

- χ i (i = 1, 2):

-

The modification coefficient

- FE:

-

Finite element

- LDP:

-

Load distribution program

- IAM:

-

Improved analytical method

- ISO:

-

International Standardization Organization

- TVMS:

-

Time-varying mesh stiffness

- WB:

-

Weber and Banaschek’s formulae

References

Wan ZG, Cao HR, Zi YY, He WP, He ZJ (2014) An improved time-varying mesh stiffness algorithm and dynamic modeling of gear-rotor system with tooth root crack. Eng Fail Anal 42:157–177

Chen ZG, Shao YM (2013) Mesh stiffness calculation of a spur gear pair with tooth profile modification and tooth root crack. Mech Mach Theory 62:63–74

Velex P, Bruyère J, Houser DR (2011) Some analytical results on transmission errors in narrow-faced spur and helical gears: influence of profile modifications. ASME J Mech Des 133:1–11

Fernández A, Iglesias M, de-Juan A, García P, Sancibrián R, Viadero F (2014) Gear transmission dynamic: effects of tooth profile deviations and support flexibility. Appl Acoust 77:138–149

Cai Y (1995) Simulation on the rotational vibration of helical gears in consideration of the tooth separation phenomenon (a new stiffness function of helical involute tooth pair). J Mech Des 117(3):460–469

Umezawa K, Suzuki T, Sato T (1986) Vibration of power transmission helical gears: approximate equation of tooth stiffness. Bull JSME 29(251):1605–1611

He S, Gunda R, Singh R (2007) Inclusion of sliding friction in contact dynamics model for helical gears. J Mech Des 129(1):48–57

Zhu CC, Lu B, Song CS, Qin DT (2009) Dynamic analysis of a heavy duty marine gearbox with gear mesh coupling. Proc Instit Mech Eng Part C J Mech Eng Sci 223(11):2531–2547

Gu X, Velex P, Sainsot P, Bruyère J (2015) Analytical investigations on the mesh stiffness function of solid spur and helical gears. ASME J Mech Des 137(6):1–7

Wang QB, Zhang YM (2017) A model for analyzing stiffness and stress in a helical gear pair with tooth profile errors. J Vib Control 23(2):272–289

Wan ZG, Cao HR, Zi YY, He WP, Chen YM (2015) Mesh stiffness calculation using an accumulated integral potential energy method and dynamic analysis of helical gears. Mech Mach Theory 92:447–463

Jiang HJ, Shao YM, Mechefske CK (2014) Dynamic characteristics of helical gears under sliding friction with spalling defect. Eng Fail Anal 39:92–107

Shao YM, Su DZ, Al-Habaibeh A, Yu WN (2016) A new fault diagnosis algorithm for helical gears rotating at low speed using an optical encoder. Measurement 93:449–459

Mao K (2006) An approach for powertrain gear transmission error prediction using the non-linear finite element method. Part D J Autom Eng 220(10):1455–1463

Li JF, Zhang Z, Ji L, Wang SY (1998) Finite element analysis of cylindrical gears. Commun Numer Methods Eng 14(10):963–975

Litvin FL, Fuentes A, Gonzalez-Perez I, Carvenali L, Kawasaki K, Handschuh RF (2003) Modified involute helical gears: computerized design, simulation of meshing and stress analysis. Comput Methods Appl Mech Eng 192:3619–3655

Barbieri M, Zippo A, Pellicano F (2014) Adaptive grid-size finite element modeling of helical gear pairs. Mech Mach Theory 82:17–32

Palermo A, Mundo D, Hadjit R, Desmet W (2013) Multibody element for spur and helical gear meshing based on detailed three-dimensional contact calculations. Mech Mach Theory 62:13–30

Chang LH, Liu G, Wu LY (2015) A robust model for determining the mesh stiffness of cylindrical gears. Mech Mach Theory 87:93–114

Ding YF, Liu L, Wu LY, Chang LH (2014) The changing rule of the helical cylindrical gear meshing stiffness fluctuation. Mech Transm 38(5):24–27 (in Chinese)

Eritenel T, Parker RG (2012) Three-dimensional nonlinear vibration of gear pairs. J Sound Vib 331:3628–3648

Hedlund J, Lehtovaara A (2008) A parameterized numerical model for the evaluation of gear mesh stiffness variation of a helical gear pair. Proc Instit Mech Eng Part C J Mech Eng Sci 222(7):1321–1327

Ma H, Zeng J, Feng RJ, Pang X, Wang QB, Wen BC (2015) Review on dynamics of cracked gear systems. Eng Fail Anal 55:224–245

Smith JD (2003) Gear noise and vibration. Marcel Dekker, Cambridge, pp 35–40

Sean W (2001) Face gear contact analysis program development using the thin slice method. The Ohio State University, Ohio

Jiang HJ, Liu FH (2016) Dynamic features of three-dimensional helical gears under sliding friction with tooth breakage. Eng Fail Anal 70:305–322

Saxena A, Parey A, Chouksey M (2015) Effect of shaft misalignment and friction force on time varying mesh stiffness of spur gear pair. Eng Fail Anal 49:79–91

He S, Singh R (2008) Dynamic transmission error prediction of helical gear pair under sliding friction using floquet theory. ASME J Mech Des 130:1–9

Marques PMT, Martins RC, Seabra JHO (2016) Power loss and load distribution models including frictional effects for spur and helical gears. Mech Mach Theory 96:1–25

Rebbechi B, Oswald FB, Townsend DP (1996) Measurement of gear tooth dynamic friction, power transmission and gearing conference, San Diego, United States

Ma H, Pang X, Feng RJ, Wen BC (2016) Evaluation of optimum profile modification curves of profile shifted spur gears based on vibration responses. Mech Syst Signal Process 70–71:1131–1149

Ma H, Zeng J, Feng RJ, Pang X, Wen BC (2016) An improved analytical model for mesh stiffness calculation of spur gears with tip relief. Mech Mach Theory 98:64–80

Ma H, Feng MJ, Li ZW, Feng RJ, Wen BC (2017) Time-varying mesh characteristics of a spur gear pair considering the tip-fillet and friction. Meccanica 52(7):1695–1709

Tavakoli MS, Houser DR (1986) Optimum profile modifications for the minimization of static transmission errors of spur gears. ASME J Mech Des 108(1):86–94

Cai Y, Hayashi T (1994) The linear approximated equation of a pair of spur gears (theory and experiment). J Mech Des 116(2):558–564

Acknowledgements

This project is supported by the Joint Funds of the National Natural Science Foundation and the Civil Aviation Administration of China (Grant No. U1433109), the Fundamental Research Funds for the Central Universities (Grant Nos. N150305001 and N160313004), State Key Laboratory for Strength and Vibration of Mechanical Structures (Grant No. SV2015-KF-08) and National Natural Science Foundation of China (Grant No. 51605361) for providing financial support for this work. We also thank the anonymous reviewers for their valuable comments and Linyang Che from the Northeastern University for the proof reading of the final version of the paper and offering suggestions on the improvement of presentation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that they have no conflicts of interest.

Appendices

Appendix 1: Calculation formulas for contact ratio

The transverse contact ratio ε α and the overlap contact ratio ε β can be calculated by:

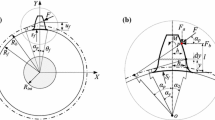

where Z 1 is the tooth number of the driving gear; L is the tooth width, r b1 is the radius of the base circle of driving gear, β b is the helix angle of the base circle. α max is the maximum pressure angle, which corresponds to the pressure angle of the meshing point D (see Fig. 13). α min is the minimum pressure angle, which corresponds to the pressure angle of the meshing point A (see Fig. 13). β b, α max and α min can be calculated as follows:

where r 1 is the radius of the pitch circle, r b1 and r b2 are the radii of the base circles of the driving and driven gears, r a1 and r a2 are the radii of the addendum circle of the driving and driven gears, α t is the transverse pressure angle, α a1 and α a2 are the pressure angles of addendum circles of the driving and driven gears, respectively, and they can be calculated by: \(\alpha_{{{\text{a}}1}} = \arccos (r_{{{\text{b}}1}} /r_{{{\text{a}}1}} ),\,\,\alpha_{{{\text{a}}2}} = \arccos (r_{{{\text{b}}2}} /r_{{{\text{a}}2}} )\).

Appendix 2: Tooth stiffness calculation considering the effects of the friction coefficient and the addendum modification coefficient

Considering the effects of the friction coefficient [33] and the addendum modification coefficient [31], the bend stiffness k b, the shear stiffness k s and the axial compressive stiffness k a can be given as follow:

where α t denotes the transverse pressure angle, \((\tau_{ 1 ,i}^{n} )_{j}\) denotes the operating pressure angle of the ith tooth pair of the nth gear slice of the driving gear at meshing position j, γ and τ denote the angular displacements of arbitrary point at the transition curve and the involute curve, E and G are Young’s modulus and Shear modulus, θ 1 and θ P can be found in Fig. 13. τ C denotes the meshing angle at the position of the involute starting point, and \(\tau_{C} = \arccos (r_{\text{b1}} /r_{C} ) - \theta_{\text{b1}} + {\text{inv(}}\arccos (r_{\text{b1}} /r_{C} ) ) ,\) \(r_{C} = \sqrt {(r_{\text{b1}} \tan \alpha_{\text{t}} - (h_{\text{at}} - \chi_{1} )m_{\text{t}} /\sin \alpha_{\text{t}} )^{2} + r_{\text{b1}}^{2} }\). I y1, I y2, A y1, A y2, x 1, y 1, x 2, y 2, x τ , y τ , dy 1/dγ, dy 2/dτ can be expressed as:

where \(\varPhi = (a_{1} /\tan \gamma + b_{1} )/r_{1}\), \(\theta_{{{\text{b}}1}} = (\uppi + 2\chi_{1} \tan \alpha_{\text{t}} )/2Z_{1} + {\text{inv}}\alpha_{\text{t}}\) denotes the half tooth angle corresponding to base circle of the driving gear with addendum coefficient, r 1 denotes the radius of the pitch circle of the driving gear, \(r_{\rho } = c_{\text{t}} m_{\text{t}} /(1 - \sin \alpha_{\text{t}} )\), \(a_{1} = (h_{\text{at}} + c_{\text{t}} )m_{\text{t}} - r_{\rho } - \chi_{1} m_{\text{t}}\), \(b_{1} =\uppi\,m_{\text{t}} /4 + h_{\text{at}} m_{\text{t}} \tan \alpha_{\text{t}} + r_{\rho } \cos \alpha_{\text{t}}\), h at denotes transverse addendum coefficient, c t denotes the transverse tip clearance coefficient, m t denotes the transverse module, and χ 1 denotes the addendum modification coefficient of driving gear.

Rights and permissions

About this article

Cite this article

Feng, M., Ma, H., Li, Z. et al. An improved analytical method for calculating time-varying mesh stiffness of helical gears. Meccanica 53, 1131–1145 (2018). https://doi.org/10.1007/s11012-017-0746-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-017-0746-6