Abstract

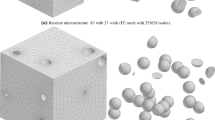

The behavior of a non-uniform void distribution in a ductile material is investigated by using a cell model analysis to study a material with a periodic pattern of void clusters. The special clusters considered consist of a number of uniformly spaced voids located along a plane perpendicular to the maximum principal tensile stress. A plane strain approximation is used, where the voids are parallel cylindrical holes. Clusters with different numbers of voids are compared with the growth of a single void, such that the total initial volume of the voids, and thus also the void volume fractions, are the same for the clusters and the single void. In the comparison it is essential that local void coalescence inside the clusters is accounted for, since this allows for considering the rate of growth of the single larger void that results from coalescence in the cluster. To obtain a parametric understanding, different transverse stresses on the unit cell are considered to see the influence of different levels of stress triaxiality. Also considered are different initial ratios of the void spacing to the void radius inside the clusters. And results are shown for different levels of strain hardening in the material.

Similar content being viewed by others

References

Bandstra JP, Koss DA (2008) On the influence of void clusters on void growth and coalescence during ductile fracture. Acta Mater 56:4429–4439

Benzerga AA, Leblond J-B (2010) Ductile fracture by void growth to coalescence. Adv Appl Mech 44:169–305

Benzerga AA, Leblond J-B, Needleman A, Tvergaard V (2016) Ductile failure modelling. Int J Fracture (In press)

Chiantoni G, Comi C, Mariani S, Bonora N (2014) Experimental assessment of ductile damage in P91 steel at high temperature. Int J Damage Mech 23(4):567–587

Danas K, Castaneda PP (2009) A finite-strain model for anisotropic viscoplastic media: I—theory. Eur J Mech A/Solids 28:387–401

Danas K, Castaneda PP (2009) A finite-strain model for anisotropic viscoplastic media: II—applications. Eur J Mech A/Solids 28:402–416

Garrison WM Jr, Moody NR (1987) Ductile fracture. J Phys Chem Solids 48(11):1035–1074

Geltmacher AB, Koss DA, Matic P, Stout MG (1996) A modeling study of the effect of stress state on void linking during ductile fracture. Acta Mater 44:2201–2210

Gologanu M, Leblond J, Perrin G, Devaux J (1997) Recent extensions of Gurson’s model for porous ductile metals. Continuum micromechanics. Springer, Berlin, pp 61–106

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth—I. yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99:2–15

Hutchinson JW (1973) Finite strain analysis of elastic-plastic solids and structures. In: Hartung RF (ed) Numerical solution of nonlinear structural problems. ASME, New York, p 17

McClintock FA (1968) A criterion for ductile fracture by growth of holes. J Appl Mech 35:363–371

Nielsen KL, Dahl J, Tvergaard V (2012) Collapse and coalescence of spherical voids subject to intense shearing: studied in full 3D. Int J Fract 177:97–108

Ohno N, Hutchinson JW (1984) Plastic flow localization due to non-uniform void distribution. J Mech Phys Solids 32(1):63–85

Pardoen T, Hutchinson JW (2000) An extended model for void growth and coalescence. J Mech Phys Solids 48:2467–2512

Pedersen TØ (1998) Remeshing in analysis of large plastic deformations. Comput Struct 67:279–288

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields. J Mech Phys Solids 17:201–217

Scheyvaerts F, Onck PR, Bréchet Y, Pardoen T (2006) Void growth and coalescence under general loading conditions. Report, Université catholique de Louvain

Scheyvaerts F, Onck PR, Tekoglu C, Pardoen T (2011) The growth and coalescence of ellipsoidal voids in plane strain under combined shear and tension. J Mech Phys Solids 59:373–397

Thomson CIA, Worswick MJ, Pilkey AK, Lloyd DJ, Burger D (1999) Modeling void nucleation and growth within periodic clusters of particles. J Mech Phys Solids 47:1–26

Thomson CIA, Worswick MJ, Pilkey AK, Lloyd DJ (2003) Void coalescence within periodic clusters of particles. J Mech Phys Solids 51:127–146

Tinet H, Klöcker H, Le Coze J (2004) Damage analysis during hot deformation of a resulfurized stainless steel. Acta Mater 52:3825–3842

Tvergaard V (1976) Effect of thickness inhomogeneities in internally pressurized elastic-plastic spherical shells. J Mech Phys Solids 24:291

Tvergaard V (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17:389–407

Tvergaard V (1990) Material failure by void growth to coalescence. Adv Appl Mech 27:83–151

Tvergaard V (1997) Studies of void growth in a thin ductile layer between ceramics. Comput Mech 20:186–191

Tvergaard V (2004) On fatigue crack growth in ductile materials by cracktip blunting. J Mech Phys Solids 52:2149–2166

Tvergaard V (2007) Discrete modelling of ductile crack growth by void growth to coalescence. Int J Fract 148:1–12

Tvergaard V (2008) Shear deformation of voids with contact modeled by internal pressure. Int J Mech Sci 50:1459–1465

Tvergaard V (2009) Behaviour of voids in a shear field. Int J Fract 158:41–49

Tvergaard V (2012) Effect of stress-state and spacing on voids in a shear-field. Int J Solids Struct 49:3047–3054

Tvergaard V, Hutchinson JW (2002) Two mechanisms of ductile fracture: void by void growth versus multiple void interaction. Int J Solids Struct 39:3581–3597

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32:157–169

Tvergaard V, Needleman A (1992) Effect of crack meandering on dynamic, ductile fracture. J Mech Phys Solids 40:447–471

Tvergaard V, Needleman A (2006) Three dimensional microstructural effects on plane strain ductile crack growth. Int J Solids Struct 43:6165–6179

Acknowledgments

This study was partially supported by the Technical University of Denmark.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest.

Rights and permissions

About this article

Cite this article

Tvergaard, V. Effect of void cluster on ductile failure evolution. Meccanica 51, 3097–3105 (2016). https://doi.org/10.1007/s11012-016-0537-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-016-0537-5