Abstract

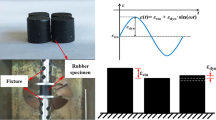

Rheological models are used for the description of viscoelastic properties. Such investigations are mostly based on experiments with a torsional rheometer, i.e. a Rubber Process Analyzer. The results of such experiments are storage and loss modulus, which depend on the applied angular frequency. The investigations were performed with rubber compounds used in industry, with different crystallization degrees of the used EPDM basic polymer as well as different filler degrees. Moreover, the influence of melt temperature on these dynamic moduli is considered. For the rheological description of the investigated rubber compounds three different viscoelastic models are used. After derivation of the corresponding relationships for each of the spring-dashpot models the application for rubber compounds was investigated. The best agreement between experiment and model prediction was achieved by a nonlinear viscoelastic model. With such a model the influence of different crystallization and filler degrees on the viscoelastic material properties can be covered.

Similar content being viewed by others

References

Cole KS, Cole RH (1941) Dispersion and absorption in dielectrics, I: alternating current characteristics. J Chem Phys 9:341–351

Dick JS, Harmon C, Vare A (1999) Quality assurance of natural rubber using the rubber process analyzer. Polym Test 18:327–362

Findley WN, Lai JS, Onaran K (1976) Creep and relaxation of nonlinear viscoelastic materials. Dover, New York

Gross B (1953) Mathematical structure of the theories of viscoelasticity. Hermann, Paris

Huet C (1963) Etude par une méthode d’impédance du comportement viscoélastique des matériaux hydrocarbonés. PhD thesis, Université de Paris I Panthéon Sorbonne

Jäger A, Lackner R (2005) Nanoscale characterization of bitumen—back analysis of viscoelastic properties. In: Proceedings of the 6th European symposium on nanomechanical testing, pp 22–23

Maxwell JC (1867) On the dynamical theory of gases. Philos Trans R Soc Lond 157:49–88

Müllner HW, Eberhardsteiner J, Wieczorek A (2006) Experimental investigation and identification of material parameters for rubber blends. Arch Mech Eng 53:263–278

Pahl M, Gleißle W, Laun HM (1995) Praktische Rheologie der Kunststoffe und Elastomere. VDI-Gesellschaft Kunststofftechnik, Düsseldorf

Roylance DK (1996) Mechanics of Materials. Wiley, New York

Wiechert E (1893) Gesetze der elastischen Nachwirkung für constante Temperatur I. Wiedemann’s Ann Phys Chem 50:336–348

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Müllner, H.W., Jäger, A., Aigner, E.G. et al. Experimental identification of viscoelastic properties of rubber compounds by means of torsional rheometry. Meccanica 43, 327–337 (2008). https://doi.org/10.1007/s11012-007-9097-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-007-9097-z