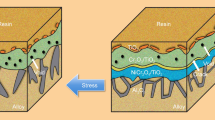

A cast Ni-based superalloy strengthened by hafnium carbides was cast and characterized at 1100°C in creep and in hot oxidation. The as-cast microstructure formed by a dendritic matrix and eutectic scriptlike hafnium carbides (HfC) imbricated with the matrix in the interdendritic spaces is very favorable for its high mechanical properties at high temperature. This was confirmed by a three-point flexural creep test carried out at 1100°C under 20 MPa. The slow parabolic mass-gain kinetics showed that this alloy is very resistant against oxidation at 1100°C in air. The HfC carbides remained stable during these tests. The oxidation behavior was chromia-forming. This alloy is ready to be used in structural applications at a temperature reachable by only γ/γ′ Ni-based single-crystals or ODS superalloys.

Similar content being viewed by others

References

C. H. Lund and J. Hockin, “Investment casing,” in: C. T. Sims and W. C. Hagel (editors), The Superalloys, John Wiley and Sons, New York (1972), pp. 423–425.

P. Berthod, L. Aranda, C. Vébert, and S. Michon, “Experimental and thermodynamic study of the microstructural state at high temperature of nickel-base alloys containing tantalum,” Calphad, 28, No. 2, 159–166 (2004).

P. Berthod, “High-temperature properties of several chromium-containing Co-based alloys reinforced by different types of MC carbides (M = Ta, Nb, Hf, and/or Zr),” J. Alloys Compounds, 481, 746–754 (2009).

P. Berthod and E. Conrath, “Microstructure evolution in the bulk and surface states of chromium-rich nickel-based cast alloys reinforced by hafnium carbides after exposure to high temperature in air,” Mater. High Temper., 31, No. 3, 266–273 (2014).

O. I. Balyts’kyi, V. М. Mochylski, and L. М. Ivaskevich, “Evaluation of the influence of hydrogen on the mechanical characteristics of complexly alloyed nickel alloys,” Fiz.-Khim. Mekh. Mater., 51, No. 4, 91–99 (2015); English translation : Mater. Sci., 51, No. 4, 538–547 (2016).

A. Balitskii, V. Vytvytskyii, L. Ivaskevich, and J. Eliasz, “The high- and low-cycle fatigue behavior of Ni-containing steels and Ni-alloys in high-pressure hydrogen,” Int. J. Fatigue, 39, 32–37 (2012).

P. Berthod, “Kinetics of high-temperature oxidation and chromia volatilization for a binary Ni–Cr alloy,” Oxid. Metals, 64, No. 3–4, 235–252 (2005).

Acknowledgments

The authors wish to thank Th. Schweitzer and P. Villeger for their help.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Fizyko-Khimichna Mekhanika Materialiv, Vol. 53, No. 6, pp. 104–109, November–December, 2017.

Rights and permissions

About this article

Cite this article

Conrath, E., Berthod, P. Properties of a HfC-Reinforced Nickel-Based Superalloy in Creep and Oxidation at 1100°C. Mater Sci 53, 861–867 (2018). https://doi.org/10.1007/s11003-018-0146-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-018-0146-7