Abstract

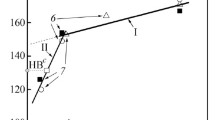

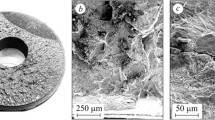

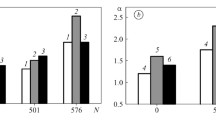

We have shown that hardness, impact toughness, mechanical properties in tension, and the local parameters of fracture mechanics (static and cyclic crack resistance) are sensitive to the operating degradation of weld metal of steam pipelines of thermal power plants made of 15Kh1M1F steel. The simultaneous decrease in the resistance to brittle and plastic fracture (hardness, strength, and impact toughness) represents a phenomenon of the operating degradation of weld metal. We have established a specific correlation between the characteristics of plasticity and other mechanical parameters of operated metal: the increase in °5 of operated weld metal is in good agreement with the decrease in its strength, whereas the reduction of Ψ correlates with the lowering of resistance to brittle fracture. Electrolytic hydrogenation decreases the characteristics of strength and plasticity of operated weld metal much stronger than in the initial state. The absence of ferritic edgings on the boundaries of primary austenitic grains makes for a low resistance to brittle fracture, and the change in acicular ferrite deteriorates the mechanical properties. The ductile fracture of nonoperated metal is replaced by brittle intercrystalline failure in operated metal.

Similar content being viewed by others

References

O. M. Romaniv, H. M. Nykyforchyn, O. Z. Student, et al., “Effect of the operating damage of 12Kh1MF steam-pipeline steel on the characteristics of its crack resistance,” Fiz.-Khim. Mekh. Mater., 34, No. 1, 101–104 (1998).

H. M. Nykyforchyn and O. Z. Student, “Thermocycling in hydrogen environment as simulation method of pipeline steam steel’s damages,” in: M. W. Brown, E. R. de los Rios, and K. J. Miller (editors), Proc. 12th Biennial Conf. Fracture-ECF12 “Fracture from Defects” (Sheffield, 1998), Vol. III, EMAS, London (1998), pp. 1139–1144.

H. Nykyforchyn and O. Student, “Evaluation of the high-temperature hydrogen degradation of steels of power-generating and petrochemical equipment by the methods of fracture mechanics,” in: V. V. Panasyuk (editor), Fracture Mechanics of Materials and Strength of Structures [in Ukrainian], Karpenko Physicomechanical Institute, Ukrainian National Academy of Sciences, Lviv (2004), pp. 633–640.

V. V. Panasyuk, H. M. Nykyforchyn, O. Z. Student, and Z. V. Slobodyan, “Application of the approaches of fracture mechanics to the evaluation of hydrogen degradation of the steels of oil and steam pipelines,” in: O. E. Andreikiv, I. I. Luchko, and V. V. Bozhydarnyk (editors), Mechanics and Physics of the Fracture of Building Materials and Structures [in Ukrainian], Kamenyar, Lviv (2002), pp. 537–546.

O. Z. Student, “An accelerated method of hydrogen degradation of structural steels by thermocycling,” Fiz.-Khim. Mekh. Mater., 34, No. 4, 45–52 (1998).

O. Z. Student, W. Dudzinski, A. Kaminska, and H. M. Nykyforchyn, “Effect of high-temperature degradation of heat-resistant steel on mechanical and fractographic peculiarities of fatigue crack growth,” Fiz.-Khim. Mekh. Mater., 35, No. 4, 49–58 (1999).

H. M. Nykyforchyn, O. Z. Student, I. R. Dzioba, et al., “Degradation of the welded joints of steam pipelines of thermal power plants in a hydrogenating medium,” Fiz.-Khim. Mekh. Mater., 40, No. 6, 105–110 (2004).

O. Z. Student, A. D. Markov, and H. M. Nykyforchyn, “Specific features of the influence of hydrogen on the properties and mechanism of fracture of the metal of welded joints of steam pipelines at thermal power plants,” Fiz.-Khim. Mekh. Mater., 42, No. 4, 26–35 (2006).

SOU-N MPE 40.1.17.401:2004. Normative Document. Directions. Control of the Metal and Prolongation of the Service Life of the Main Elements of Boilers, Turbines, and Pipelines of Thermal Power Plants. Typical Instruction [in Ukrainian], Association of Power Enterprises “Branch Reserve-Investment Fund of the Development of Power Engineering,” Kyiv (2005).

A. M. Makara, V. I. Lakomskii, and I. P. Zhovnitskii, “A study of hydrogen distribution in the welded joints of middle-alloy steels with austenitic and ferritic welds,” Avtom. Svarka, No. 11, 23–29 (1958).

V. I. Makhnenko, T. V. Koroleva, and I. G. Lavrinets, “Effect of microstructural changes on the hydrogen redistribution in the fusion welding of structural steels,” Avtom. Svarka, No. 2, 7–13 (2002).

H. K. D. H. Bhadeshia and L.-E. Svensson, “Modelling the evolution of microstructure in steel weld metal,” in: H. Cerjak (editor), Mathematical Modelling of Weld Phenomena, Institute of Materials, London (1993), pp. 109–182.

S. S. Babu and H. K. D. H. Bhadeshia, “Transition from bainite to acicular ferrite in reheated Fe-Cr-C weld deposits,” Mater. Sci. Tech., 6, No. 10, 1005–1020 (1990).

K. Ichikawa and H. K. D. H. Bhadeshia, “Modelling of allotriomorphic ferrite in steel welds,” in: Mathematical Modelling of Weld Phenomena-3, Institute of Materials, London (1997), pp. 181–198.

P. A. Antikain, L. I. Ryabova, and A. V. Aksenov, “To the evaluation of serviceability of steam pipelines made of perlitic steels after long-term operation,” Probl. Prochn., No. 7, 35–42 (1971).

A. B. Vainman, R. K. Melekhov, and O. D. Smiyan, Hydrogen Embrittlement of Elements of High-Pressure Boilers [in Russian], Naukova Dumka, Kiev (1990).

O. Z. Student and H. V. Krechkovs’ka, “Evaluation of the technical state of the metal of steam pipelines with regard for the influence of stoppages in the operation of blocks of thermal power plants,” in: Problems of the Lifetime and Safety of Operation of Structures, Installations, and Machines [in Ukrainian], Institute of Electric Welding, Kyiv (2006), pp. 563–566.

Author information

Authors and Affiliations

Additional information

__________

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 43, No. 1, pp. 73–79, January–February, 2007.

Rights and permissions

About this article

Cite this article

Nykyforchyn, H.M., Student, O.Z. & Markov, A.D. Abnormal manifestation of the high-temperature degradation of the weld metal of a low-alloy steel welded joint. Mater Sci 43, 77–84 (2007). https://doi.org/10.1007/s11003-007-0008-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11003-007-0008-1