Abstract

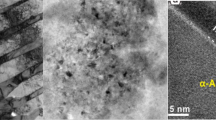

Nanocrystalline materials have special physical, chemical, and mechanical properties. To a significant extent, these properties are attributed to a high density of grain boundaries and other defects in nanocrystalline compounds. We study the microstructure and mechanical properties of nanomaterials (Al, Al-alloys, Cu, Ni, Ti, and stainless steel) and nanocomposites (Al2O3/Ni-P) by the methods of transparent and scanning electron microscopy, X-ray diffraction analysis, and microhardness and tensile tests. The experimental methods include the procedures of measuring the electric and corrosion resistances. The materials are prepared by using contemporary methods, namely, by hydrostatic extrusion (nanometals) and by sintering ceramic powders covered with Ni-P nanoparticles under high pressure by using the procedure of nonelectric chemical metallization (Al2O3/Ni-P nanocomposites).

Similar content being viewed by others

References

R. Z. Valiev, R. K. Islamgaliev, and I. V. Aleksandrov, “Bulk nanostructured materials from severe plastic deformation,” Progress Mat. Sci., 45, 103 (2000).

M. Furukawa, Z. Horita, M. Nemoto, and T. G. Langdon, “The use of severe plastic deformation for microstructural control,” Mat. Sci. Eng., A324, 82 (2002).

P. B. Prangnell, J. R. Bowen, and P. J. Apps, “Ultra-fine grain structures in aluminium alloys by severe deformation processing,” Mat. Sci. Eng., A375-377, 178 (2004).

R. Z. Valiev, A. V. Sergeyeva, and A. K. Mukherjee, “The effect of annealing on tensile deformation behavior of nanostructured SPD titanium,” Scripta Mater., 49, 669 (2003).

Z. Horita, T. Fujinami, M. Nemoto, and T. G. Langdon, “Improvement of mechanical properties for Al alloys using equal-channel angular pressing,” J. Mat Proc. Tech., 117, 288 (2001).

R. Z. Valiev, D. A. Salimonenko, N. K. Tsenev, B. Berbon, and T. G. Langdon, “Observation of high strain rate superplasticity in commercial aluminum alloys with ultrafine grain size,” Scripta Mater., 37, 1945 (1997).

M. A. Munos-Morris, C. Garcia Oca, and D. G. Morris, “Mechanical behaviour of dilute Al-Mg alloy processed by equal channel angular pressing,” Scripta Mater., 48, 213 (2003).

N. Tsuji, Y. Ito, Y. Saito, and Y. Minamino, “Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing,” Scripta Mater., 47, 893 (2002).

C. Y. Barlow, P. Nielsen, and N. Hansen, “Multilayer roll bonded aluminium foil: processing, microstructure, and flow stress,” Acta Mater., 52, 3967 (2004).

K. Neishi, Z. Horita, and T. G. Langdon, “Achieving superplasticity in Cu-40% Zn alloy through severe plastic deformation,” Scripta Mater., 45, 965 (2001).

V. M. Segal, “Materials processing by simple shear,” Mater. Sci. Eng., A197, 157 (1995).

Y. Iwahashi, Z. Horita, M. Nemoto, and T. G. Langdon, “The process of grain refinement in equal-channel angular pressing,” Acta Mater., 46, 3317 (1998).

A. P. Zhilayaev, B.-K. Kim, G. V. Nurislamova, et al., “Orientation imaging microscopy of ultrafine-grained nickel,” Scripta Mater., 46, 575 (2002).

M. Richert, Q. Liu, and N. Hansen, “Microstructural evolution over a large strain range in aluminium deformed by cyclic-extrusion-compression,” Mat. Sci. Eng., A260, 275 (1999).

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, “Novel ultra-high straining process for bulk materials —development of the accumulative roll-bonding (ARB) process,” Acta Mater., 47, 579 (1999).

J. Y. Huang, Y. T. Zhu, H. Jiang, and T. C. Lowe, “Microstructures and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening,” Acta Mater., 49, 1497 (2001).

A. P. Zhilayaev, G, V. Nurislamova, B.-K. Kim, et al., “Experimental parameters influencing grain refinement and microstructural evolution during high-pressure torsion,” Acta Mater., 51, 753 (2002)

N. Tsuji, R. Ueji, Y. Minamino, and Y. Saito, “A new and simple process to obtain nano-structured bulk low-carbon steel with superior mechanical property,” Scripta Mater., 46, 305 (.2002).

Y. Iwahashi, J. Wang, Z. Horita, et al., “Principle of equal-channel angular pressing of ultra-fine grained materials,” Scripta Mater., 35, 143 (1996).

T. Hebesberger, H. P. Stuwe, A. Vorhauer, et al., “Structure of Cu deformed by high-pressure torsion,” Acta Mater., 53, 393 (2005).

M. Lewandowska, H. Garbacz, W. Pachia, et al., “Hydrostatic extrusion and nanostructure formation in an aluminium alloy,” Solid State Phen., 101, 65 (2005).

B. Adamczyk-Cieślak, J. Mizera, M. Lewandowska, and K. J. Kurzydłowski, “ Microstructure evaluation in an Al-Li alloy processed by severe plastic deformation,” Rev. Adv. Mater. Sci., 8, 107 (2004).

K. J. Kurzydłowski, H. Garbacz, and M. Richert, “Effect of severe plastic deformation on the microstructure and mechanical properties of Al and Cu,” Rev. Adv. Mater. Sci., 8, 129 (2004).

S. Gierlotka, B. F. Palosz, A. Swiderska-Sroda, et al., “Synthesis of metal-ceramic nanocomposites by high pressure infiltration,” Solid State Phen., 101-102, 157–164 (2005).

B. Faber, E. Cadel, A. Menand, et al., “Phosphorus segregation in nanocrystalline Ni-3.6 at.% P alloy investigated with the tomographic atom probe,” Acta Materialia, 48, 789–796 (2000).

J. Bielinski, I. Kulak, A. Bielinska, J. Michalski, “Bezprądowe niklowanie materiał ów litych i proszkowych,” Ochrona Przed Korozją, 46(11A), 233–237 (2003).

J. F. Cannon, “Behavior of the elements at high pressures,” Phys. Chem. Ref. Data, 3, No. 3, 781–824 (1974).

J. Michalski, K. Konopka, S. Gierlotka, and K. J. Kurzydłowski, “Influence of temperature and pressure on the possibility of obtaining Al2O3/Ni-P nanocomposites through hot pressing process,” Solid State Phen., 101-102, 147–150 (2005).

T. B. Massalski, H. Okamoto, R. Subramanian, and L. Kacprzyk, Binary Alloy Phase Diagrams, 2nd Ed., Vol. 3, SAM Int., Materials Park, OH (1992).

Author information

Authors and Affiliations

Additional information

Published in Fizyko-Khimichna Mekhanika Materialiv, Vol. 42, No. 1, pp. 82–89, January–February, 2006.

Rights and permissions

About this article

Cite this article

Kurzydlowski, K.J. Physical, chemical, and mechanical properties of nanostructured materials. Mater Sci 42, 85–94 (2006). https://doi.org/10.1007/s11003-006-0060-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11003-006-0060-2