Abstract

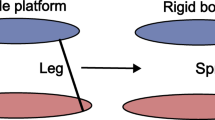

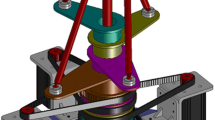

Traditional parallel manipulators suffer from errors due to backlash, hysteresis, and vibration in the mechanical joints. The hybrid mechanism is built through the reconfiguration of parallel-serial structure. In this paper, a new 3SPS + RPR spatial hybrid mechanism which has three degrees of freedom (DOF) and can generate motions in a microscopic scale is proposed. As a reliable compliant hybrid mechanism which provides micro/nano scale micromotion with high accuracy, it can be utilized for biomedical engineering and fiber optics industry. The detailed design of the structure is first introduced, followed by the kinematic analysis and performance evaluation. Based on the kinetostatic model, the joint and link compliances of the passive constraining leg are investigated. Second, a finite-element analysis of resultant stress, strain, and deformations is evaluated based upon different inputs of the three piezoelectric actuators. Finally, the genetic algorithms and radial basis function networks are implemented to search for the optimal architecture and behavior parameters in terms of global stiffness/compliance, dexterity and manipulability. The proposed analysis and optimization methodology is intuitive and effective that offers a constructive way for design optimization of the family of parallel/hybrid manipulators.

Similar content being viewed by others

References

Bamberger, H., Shoham, M.: A novel six degrees-of-freedom parallel robot for MEMS fabrication. IEEE Trans. Robot. 23, 189–195 (2007)

Chablat, D., Angeles, J.: On the kinetostatic optimization of revolute-coupled planar manipulators. Mech. Mach. Theory 37, 351–374 (2002)

Cheng, H., Yiu, Y., Li, Z.X.: Dynamics and control of redundantly actuated parallel manipulators. IEEE/ASME Trans. Mechatron. 8, 483–491 (2003)

Coello, C.A., Veldhuizen, D.A., Lamont, G.B.: Evolutionary Algorithms for Solving Multi-Objective Problems. Kluwer Academic Publishers, New York (2002)

Dong, W., Sun, L.N., Du, Z.J.: Design of a precision compliant parallel positioner driven by dual piezoelectric actuators. Sens. Actuator A: Phys. 135, 250–256 (2007)

Fang, S.Q., Franitza, D., Torlo, M., Bekes, F., Hiller, M.: Motion control of a tendon-based parallel manipulator using optimal tension distribution. IEEE/ASME Trans. Mechatron. 9(9), 561–568 (2004)

Fieldsend, J.E., Singh, S.: Pareto evolutionary neural networks. IEEE Trans Neural Netw. 16, 338–354 (2005)

Gao, Z., Zhang, D., Hu, X., Ge, Y.: Design, analysis and stiffness optimization of a three-degree-of-freedom parallel manipulator. Robotica 28, 349–357 (2010)

Golbabai, A., Seifollahi, S.: Radial basis function networks in the numerical solution of linear integro-differential equations. Appl. Math. Comput. 188, 427–432 (2007)

Gosselin, C.M., Guillot, M.: The synthesis of manipulators with prescribed workspace. J Mech Des. 113, 451–455 (1991)

Gosselin, C.M., Zhang, D.: Stiffness analysis of parallel mechanisms using a lumped model. Int. J. Robot. Autom. 17, 17–27 (2002)

Hafez, M., Lichter, M.D., Dubowsky, S.: Optimized binary modular reconfigurable robotic devices. IEEE/ASME Trans. Mechatron. 8, 18–25 (2003)

Holland, J.: Adaptation in Natural and Artificial Systems. The University of Michigan Press, Ann Arbor, MI (1975)

Kang, B., Wen, J., Dagalakis, N., Goman, J.: Analysis and design of parallel mechanisms with flexure joints. In: Proceeding of the 2004 IEEE International Conference on Robot and Automation. New Orleans, LA, USA, 2004

Liu, X., Kim, J.: A new spatial three-dof parallel manipulator with high rotational capability. IEEE/ASME Trans. Mechatron. 10, 502–512 (2005)

Mitchell, J.H., Jacob, R., Mika, N.: Optimization of a spherical mechanism for a minimally invasive surgical robot: theoretical and experimental approaches. IEEE Trans. Bio-Med. Eng. 53(7), 1440–1445 (2006)

Molinari-Tosatti, L., Fassi, I., Legnani, G.: Kineto-static optimisation of PKMs. Ann CIRP. 52(1), 337−342 (2003)

Moon, Y.M.: Bio-mimetic design of finger mechanism with contact aided compliant mechanism. Mech. Mach. Theory 42, 600–611 (2007)

Oetomo, D., Daney, D., Shirinzadeh, B., Merlet, J.-P.: Certified workspace analysis of 3RRR planar parallel flexure mechanism. In: Proceeding of the 2008 IEEE International Conference on Robotics and Automation. Pasadena, CA, USA (2008)

Ottaviano, E., Ceccarelli, M.: Application of a 3-DOF parallel manipulator for earthquake simulations. IEEE/ASME Trans. Mechatron. 11, 241–246 (2006)

Rao, A., Rao, P., Saha, S.: Dimensional design of hexaslides for optimal workspace and dexterity. IEEE Trans. Robot. 21, 444–449 (2005)

Rout, B.K., Mittal, R.K.: Parametric design optimization of 2-DOF R-R planar manipulator: A design of experiment approach. Robot. Comput.-Integr. Manuf. 24, 239–248 (2008)

Sitti, M.: Piezoelectrically actuated four-bar mechanism with two flexible links for micromechanical flying insect thorax. IEEE/ASME Trans. Mechatron. 8, 26–36 (2003)

Sollmann, K.S., Jouaneh, M., Lavender, D.: Dynamic modeling of a two-axis, parallel, h-frame-type XY positioning system. IEEE/ASME Trans. Mechatron. 15, 280–290 (2010)

Stewart, D.: A platform with six degrees of freedom. Proc. Instn. Mech. Engrs. 80(15), 371–386 (1965–1966)

Stock, M., Miller, K.: Optimal kinematic design of spatial parallel manipulators: application to linear delta robot. J. Mech. Des. 125, 292–301 (2003)

Tadokoro, S., Murao, Y., Hiller, M., Murata, R., Kohkawa, H., Matsushima, T.: A motion base with 6-dof by parallel cable drive architecture. IEEE/ASME Trans. Mechatron. 7(2), 115–123 (2002)

Takasaki, S., Kawamura, Y.: Using radial basis function networks and significance testing to select effective siRNA sequences. Comput. Stat. Data Anal. 51, 6476–6487 (2007)

Ukidve, C.S., McInroy, J.E., Jafari, F.: Using redundancy to optimize manipulability of Stewart platforms. IEEE/ASME Trans. Mechatron. 13(4), 475–479 (2008)

Varziri, M., Notash, L.: Kinematic calibration of a wire-actuated parallel robot. Mech. Mach. Theory 42, 960–976 (2007)

Venanzi, S., Giesen, P., Parenti-Castelli, V.: A novel technique for position analysis of planar compliant mechanisms. Mech. Mach. Theory 40, 1224–1239 (2005)

Wang, L.P., Wu, J., Wang, J.S., You, Z.: An experimental study of a redundantly actuated parallel manipulator for a 5-DOF hybrid machine tool. IEEE/ASME Trans. Mechatron. 14, 72–81 (2009)

Yao, R., Tang, X., Wang, J., Huang, P.: Dimensional optimization design of the four-cable-driven parallel manipulator in FAST. IEEE/ASME Trans. Mechatron. 1–10 (2010)

Yoon, J., Ryu, J.: Design, fabrication, and evaluation of a new haptic device using a parallel mechanism. IEEE/ASME Trans. Mechatron. 6(3), 221–233 (2001)

Zhang, D.: Kinetostatics analysis and optimization of parallel and hybrid architectures for machine tools. Doctoral dissertation, Laval University, April (2000)

Zhang, D., Gosselin, C.M.: Kinetostatic modeling of parallel mechanisms with a passive constraining leg and revolute actuators. Mech. Mach. Theory 37, 599–617 (2002)

Zhu, X., Tao, G., Yao, B., Cao, J.: Adaptive robust posture control of parallel manipulator driven by pneumatic muscles with redundancy. IEEE/ASME Trans. Mechatron. 13, 441–450 (2008)

Acknowledgment

The authors would like to thank the financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC) and the help of Ms. Kayla Viegas in the preparation of the CAD model and finite element analysis. The corresponding author gratefully acknowledges the financial support from Canada Research Chairs program. The authors also acknowledge the financial support of the Italian National Research Council.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, D., Gao, Z. & Fassi, I. Design optimization of a spatial hybrid mechanism for micromanipulation. Int J Mech Mater Des 7, 55–70 (2011). https://doi.org/10.1007/s10999-011-9149-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-011-9149-3