Abstract

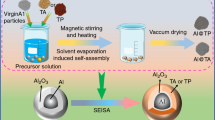

Aluminum particles have the problems of difficult ignition, easy agglomeration, incomplete combustion, etc. Therefore, it is of great scientific significance and engineering value to find ways to improve the ignition and combustion performance of aluminum particles in order to promote the full release of energy of aluminum particles. In this paper, spherical nano-sized ferric oxide (nFe2O3) and ammonium perchlorate (AP), a commonly used oxidizer in propellants, were used to synergistically improve the ignition and combustion performance of aluminum particles. AP modified the aluminum particles by both mixing and coating methods, respectively. On the basis of coating AP, nFe2O3 was added in order to further enhance the ignition and combustion performance of the aluminum particles. Scanning electron microscope, laser particle size analyzer, thermal analysis system and laser ignition experiment system were used to test the physicochemical properties and ignition combustion performance of different samples. The results showed that AP and nFe2O3 could be coated relatively uniformly on the surface of aluminum particles using the recrystallization method. The thermal reaction behavior of the samples showed that coating was beneficial to the decomposition of AP compared with mixing, and the addition of nFe2O3 could further improve the decomposition efficiency of AP. Ignition and combustion experiments showed that coating AP was more conducive to improving the ignition and combustion performance of aluminum particles than mixing AP, and the addition of nFe2O3 could further significantly enhance the combustion intensity and flame propagation speed of the sample. However, the addition of nFe2O3 increased the ignition delay time of the sample, which may be related to the cold agglomeration phenomenon caused by the nanoparticles. The microscopic combustion flame morphology of different samples showed that coating AP and the introduction of nFe2O3 could significantly reduce the agglomeration phenomenon of aluminum particles. Overall, coating AP reduces the distance between the aluminum particles and the oxidizer, thus significantly improving the ignition and combustion performance of the aluminum particles. The addition of nFe2O3 can further improve the combustion performance of aluminum particles, but at the same time, it also increases the ignition delay time. Hence, the cold agglomeration problem caused by nanoparticles should be fully considered when nFe2O3 is used to improve the ignition and combustion performance of aluminum particles.

Similar content being viewed by others

References

Waesche RHW. Mechanisms and methods of suppression of combustion instability by metallic additives. J Propul Power. 1999;15(6):919–22. https://doi.org/10.2514/2.5517.

Frienman R, Macek A. Ignition and combustion of aluminium particles in hot ambient gases. Combust Flame. 1962;6:9–19.

Ao W, Liu X, Rezaiguia H, Liu H, Wang Z, Liu P. Aluminum agglomeration involving the second mergence of agglomerates on the solid propellants burning surface: Experiments and modeling. Acta Astronaut. 2017;136:219–29. https://doi.org/10.1016/j.actaastro.2017.03.013.

Beckstead MW, Liang Y, Pudduppakkam KV. Numerical simulation of single aluminum particle combustion (review). Combust, Explos Shock Wav. 2005;41(6):622–38.

Yuan J, Liu J, Zhou Y, Wang J, Xv T. Aluminum agglomeration of AP/HTPB composite propellant. Acta Astronaut. 2019;156:14–22. https://doi.org/10.1016/j.actaastro.2018.11.009.

Ji Z, Shufen L. Aluminum oxidation in nitramine propellant. Propell Explos Pyrot. 1999;24:224–6. https://doi.org/10.1002/(sici)1521-4087(199908)24:4%3c224::aid-prep224%3e3.0.co;2-i.

DeLuca LT, Galfetti L, Severini F, Meda L, Marra G, Vorozhtsov AB, et al. Burning of nano-aluminized composite rocket propellants. Combust Explos Shock Wav. 2005;41(6):680–92.

Geisler RL. A global view of the use of aluminum fuel in solid rocket motors. 38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit; Indianapolis, Indiana 2002.

Terry BC, Gunduz IE, Pfeil MA, Sippel TR, Son SF. A mechanism for shattering microexplosions and dispersive boiling phenomena in aluminum–lithium alloy based solid propellant. Proc Combust Inst. 2017;36(2):2309–16. https://doi.org/10.1016/j.proci.2016.06.099.

Ao W, Fan Z, Liu L, An Y, Ren J, Zhao M, et al. Agglomeration and combustion characteristics of solid composite propellants containing aluminum-based alloys. Combust Flame. 2020;220:288–97. https://doi.org/10.1016/j.combustflame.2020.07.004.

Liu L, Ao W, Wen Z, Wang Y, Long Y, Liu P, et al. Modifying the ignition, combustion and agglomeration characteristics of composite propellants via Al-Mg alloy additives. Combust Flame. 2022;238:111926. https://doi.org/10.1016/j.combustflame.2021.111926.

Sippel TR, Son SF, Groven LJ. Aluminum agglomeration reduction in a composite propellant using tailored Al/PTFE particles. Combust Flame. 2014;161(1):311–21. https://doi.org/10.1016/j.combustflame.2013.08.009.

Lyu J, Yang S, Wu S, Tang G, Yang W, Yan Q. Burning rate modulation for composite propellants by interfacial control of Al@AP with precise catalysis of CuO. Combust Flame. 2022;240:112029. https://doi.org/10.1016/j.combustflame.2022.112029.

Yan Q, Zhao F, Kuo KK, Zhang X, Zeman S, DeLuca LT. Catalytic effects of nano additives on decomposition and combustion of RDX-, HMX-, and AP-based energetic compositions. Prog Energy Combust Sci. 2016;57:75–136. https://doi.org/10.1016/j.pecs.2016.08.002.

Xiao F, Liu Z, Liang T, Yang R, Li J, Luo P. Establishing the interface layer on the aluminum surface through the self-assembly of tannic acid (TA): improving the ignition and combustion properties of aluminum. Chem Eng J. 2021;420:130523. https://doi.org/10.1016/j.cej.2021.130523.

Liu L, Ao W, Wen Z, Zhang Y, Lv X, Qin Z, et al. Combustion promotion and agglomeration reduction of the composite propellant using graphene. Aerosp Sci Technol. 2021;118:106988. https://doi.org/10.1016/j.ast.2021.106988.

Zhu B, Li F, Sun Y, Wu Y, Shi W, Han W, et al. Enhancing ignition and combustion characteristics of micron-sized aluminum powder in steam by adding sodium fluoride. Combust Flame. 2019;205:68–79. https://doi.org/10.1016/j.combustflame.2019.02.007.

Lyu J, Yu J, Tang D, He W, Tao B, Guo X, et al. Unexpected burning rate independence of composite propellants on the pressure by fine interfacial control of fuel/oxidizer. Chem Eng J. 2020;388:124320. https://doi.org/10.1016/j.cej.2020.124320.

Ma Z, Li F, Bai H. Effect of Fe2O3 in Fe2O3/AP composite particles on thermal decomposition of AP and on burning rate of the composite propellant. Propellants Explos Pyrotech. 2006;31(6):447–51. https://doi.org/10.1002/prep.200600060.

DeLuca LT, Galfetti L, Colombo G, Maggi F, Bandera A, Babuk VA, et al. Microstructure effects in aluminized solid rocket propellants. J Propul Power. 2010;26(4):724–32. https://doi.org/10.2514/1.45262.

Liu J, Yuan J, Li H, Pang A, Xu P, Tang G, et al. Thermal oxidation and heterogeneous combustion of AlH3 and Al: a comparative study. Acta Astronaut. 2021;179:636–45. https://doi.org/10.1016/j.actaastro.2020.11.039.

Xu P, Liu J, Dong X, Zhang W, Yang Y, Yang W. Ignition and combustion of Al and ammonium perchlorate-coated Al particles in a double oxidizing air–H2O–Ar atmosphere. Combust Flame. 2023. https://doi.org/10.1016/j.combustflame.2023.112673.

Trunov MA, Schoenitz M, Dreizin EL. Effect of polymorphic phase transformations in alumina layer on ignition of aluminium particles. Combust Theor Model. 2006;10(4):603–23. https://doi.org/10.1080/13647830600578506.

Ao W, Liu P, Liu H, Wu S, Tao B, Huang X, et al. Tuning the agglomeration and combustion characteristics of aluminized propellants via a new functionalized fluoropolymer. Chem Eng J. 2020;382:122987. https://doi.org/10.1016/j.cej.2019.122987.

Jacobs PWM, Whitehead HM. Decomposition and combustion of ammonium perchlorate. Chem Rev. 1969;69(4):551–90. https://doi.org/10.1021/cr60260a005.

Boldyrev VV. Thermal decomposition of ammonium perchlorate. Thermochim Acta. 2006;443(1):1–36. https://doi.org/10.1016/j.tca.2005.11.038.

Schlöffel G, Eichhorn A, Albers H, Mundt C, Seiler F, Zhang F. The effect of a shock wave on the ignition behavior of aluminum particles in a shock tube. Combust Flame. 2010;157(3):446–54. https://doi.org/10.1016/j.combustflame.2009.12.001.

Servaites J, Krier H, Melcher JC, Burton RL. Ignition and combustion of aluminum particles in shocked H2O/O2/Ar and CO2/O2/Ar mixtures. Combust Flame. 2001;125(1):1040–54.

Palomino JE, Bilén SG, Cawley T, Ludwig B, Knecht SD. Combustion of aluminum powder with steam entrained in a helium plasma using a 2.45 GHZ microwave plasma torch. J Phys D Appl Phys. 2020;53(18):185204. https://doi.org/10.1088/1361-6463/ab7515.

Glorian J, Gallier S, Catoire L. On the role of heterogeneous reactions in aluminum combustion. Combust Flame. 2016;168:378–92. https://doi.org/10.1016/j.combustflame.2016.01.022.

Liao X, Liu H, Liu J, Xu P, Du L. Study on the ignition combustion and agglomeration mechanism of GAP/CL-20 composite propellants. J Therm Anal Calorim. 2023;148(10):4141–50. https://doi.org/10.1007/s10973-023-11995-8.

Takahashi K, Oide S, Kuwahara T. Agglomeration characteristics of aluminum particles in AP/AN composite propellants. Propellants, Explos, Pyrotech. 2013;38(4):555–62. https://doi.org/10.1002/prep.201200187.

Emelyanov VN, Teterina IV, Volkov KN. Dynamics and combustion of single aluminium agglomerate in solid propellant environment. Acta Astronaut. 2020;176:682–94. https://doi.org/10.1016/j.actaastro.2020.03.046.

Melcher JC, Krier H, Burton RL. Burning aluminum particles inside a laboratory-scale solid rocket motor. J Propul Power. 2002;18(3):631–40. https://doi.org/10.2514/2.5977.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liao, X., Liu, J., Xu, P. et al. AP and nFe2O3 synergistically improve the ignition and combustion performance of aluminum particles. J Therm Anal Calorim 148, 11669–11681 (2023). https://doi.org/10.1007/s10973-023-12493-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12493-7