Abstract

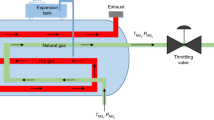

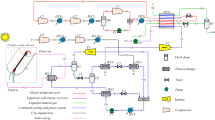

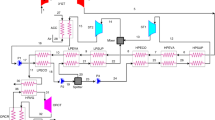

The natural gas entering the liquefaction cycle usually consists of nitrogen, ethane, propane and also heavier hydrocarbons which are economically explainable to be separated from methane, considering that their heating values are higher than methane. In this paper, a hybrid system is developed and analyzed for liquefied natural gas, natural gas liquids and power tri-generation using LNG/NGLs recovery system, absorption–compression combined refrigeration, organic Rankine cycle and solar parabolic trough collectors. This integrated structure produces 54.12 kg s−1 NGLs, 66.52 kg s−1 LNG and 278.5 MW net power output. Specific power consumption, thermal and exergy efficiencies of the hybrid system are 0.3771 kWh kg−1 LNG, 78.38% and 84.47%, respectively. The pinch method is used to extract the heat exchanger network related to the multi-stream heat exchanger of the hybrid system. To simulate the integrated structure, MATLAB programming, HYSYS and TRNSYS software with the weather conditions of Bandar Abbas city in Iran are used. The effect of natural gas composition entering the cycle on system parameters is studied and reported. Results show that with the reduction in methane percentage in natural gas to 55 mol%, specific power consumption increases to 0.6004 kWh kg−1 LNG, and thermal efficiency decreases to 71.61%. The integrated structural behavior at different operating conditions is used to investigate the sensitivity analysis.

Graphic abstract

Similar content being viewed by others

Abbreviations

- ACR:

-

Absorption–compression refrigeration

- CO2 :

-

Carbon dioxide

- COP:

-

Coefficient of performance

- C3MR:

-

Propane pre-cooled mixed refrigerant

- DMR:

-

Dual mixed refrigerant

- ES:

-

Evaporator–subcooler

- EC:

-

Evaporator–condenser

- HRSG:

-

Heat recovery steam generator

- LMTD:

-

Logarithmic mean temperature difference

- LNG:

-

Liquefied natural gas

- MFC:

-

Mixed fluid cascade

- MR:

-

Mixed refrigerant

- MCHE:

-

Main cryogenic heat exchangers

- NGLs:

-

Natural gas liquids

- ORC:

-

Organic Rankine cycle

- PTC:

-

Parabolic trough collector

- TPED:

-

Total primary energy demand

- TCI:

-

Total cost investment

- TAC:

-

Total annualized cost

- SDG:

-

Sustainable development goal

- GA:

-

Genetic algorithm

- A :

-

Area of the heat exchanger (m2)

- ACi:

-

Air cooler

- A :

-

Specific heat transfer area (m2 s kg−1)

- Ci:

-

Compressor

- D :

-

Receiver diameter (m)

- Di:

-

Flash drum

- E :

-

Specific flow exergy (kJ kg−1 mol−1)

- Ex:

-

Exergy (kW)

- H :

-

Specific enthalpy (kJ kg−1 mol−1)

- HXi:

-

Heat exchanger

- LW:

-

Lost work

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- N :

-

Molar flow rate (kg mol s−1)

- P :

-

Pressure (kPa)

- \(\dot{Q}\) :

-

Rate of heat transfer (kW)

- S :

-

Specific entropy (kJ kg−1 mol−1 °C−1)

- T :

-

Temperature (K)

- TUi:

-

Turbine

- U :

-

Overall heat transfer coefficient

- W :

-

Work (kW)

- TVi:

-

Valve

- \(r_{\text{r}}\) :

-

Rim radius (m)

- R :

-

Mirror radius (m)

- F :

-

Focal length (\({\text{m}}\))

- T r :

-

Absorber temperature (°C)

- T c :

-

Glass cover temperature (°C)

- T in :

-

The temperature of receiver inlet fluid (°C)

- \(Q_{\text{u}}\) :

-

Useful energy (W)

- T sky :

-

Sky temperature (supposed to be 6 °C less than ambient temperature)

- Nu:

-

Nusselt number of turbulent temperature (−)

- Re:

-

Reynolds number (−)

- Pr:

-

Prandtl number (−)

- m c :

-

Mass flow rate collector (kg s−1)

- m a :

-

Specific mass flow rate in tube (kg m−2 s−1)

- A a :

-

Aperture area (m2)

- k fi :

-

Thermal conductivity of the inlet fluid (W m−1 K−1)

- h fi :

-

Heat transfer coefficient of the inlet fluid (W m−2 K−1)

- h r, c-am :

-

Radiation heat transfer coefficient between cover and ambient (W m−2 K−1)

- h c, c-am :

-

Convection heat transfer coefficient between cover and ambient (W m−2 K−1)

- A c :

-

The glass cover area (m2)

- h r, r-c :

-

Radiation heat transfer coefficient from absorber to cover (W m−2 K−1)

- T amb :

-

Ambient temperature (°C)

- A r :

-

The absorber area (m2)

- U L :

-

Thermal loss coefficient from the receiver (W m−2 K−1)

- \(F^{\prime}\) :

-

The collector efficiency (–)

- D ro :

-

Receiver outer diameter (m) or glass cover diameter (m)

- D ri :

-

Receiver inner diameter (m) or absorber diameter (m)

- k m :

-

Thermal conductivity (W m−1 K−1)

- X end :

-

End loss

- C :

-

Geometric concentration ratio

- h :

-

The collector thermal efficiency

- W a :

-

Parabola aperture (m)

- X :

-

Distance along longitudinal direction of the receiver that is not illuminated

- L :

-

Length of the PTC (m)

- F R :

-

Collector heat removal factor, which shows the total useful gained energy of the collector (−)

- m c :

-

Collector mass flow rate (kg s−1)

- C p :

-

Specific heat at constant pressure (kJ kg−1 K−1)

- V air :

-

Air velocity

- G h :

-

Beam radiation (W m−2)

- η :

-

Efficiency

- Σ:

-

Sum

- ∫:

-

Integration

- \(\varepsilon_{\text{c}}\) :

-

Emittance coefficient of the glass cover (−)

- \(\varepsilon_{\text{r}}\) :

-

Emittance coefficient of the absorber (−)

- \(\sigma\) :

-

Stefan–Boltzmann constant (5.67 × 10−8 W m−2 K−4)

- \(\theta_{\text{m}}\) :

-

Half of acceptance angle (°)

- \(\Delta\) :

-

Difference

- \(\theta\) :

-

Mirror angle (°)

- \(\theta_{\text{r}}\) :

-

Rim angle (°)

- \(\eta_{\text{opt}}\) :

-

Optical efficiency; the energy gained by the absorber tube to the energy reached the collector (−)

- \(\rho\) :

-

Trough reflectance (−)

- \(\tau_{\text{env}}\) :

-

Cover transmittance (−)

- \(\alpha_{\text{r}}\) :

-

Receiver absorbance (−)

- \(\gamma\) :

-

Intercept factor (−)

- \(K\left( \theta \right)\) :

-

Incident angle correction factor

- am:

-

Ambient

- a:

-

Aperture

- C:

-

Cold

- c:

-

Condenser, cover, collector

- Ch:

-

Chemical

- D:

-

Destruction

- e:

-

Evaporator

- Ex:

-

Expander

- ev:

-

Entrained vapor

- ex:

-

Exergy

- fi:

-

Inlet fluid

- F:

-

Feed

- H:

-

Hot

- i:

-

Inlet, number of stream

- j:

-

Composition

- Id:

-

Ideal

- K:

-

Number of component

- L:

-

Loss

- min:

-

Minimum

- o:

-

Outlet

- r:

-

Radiation

- rw:

-

Reversible

- p:

-

Pressure, product

- Ph:

-

Physical

- T:

-

Thermal component

- tot:

-

Total

- 0:

-

Reference state

References

Kim H, Shin E-s, Chung W-j. Energy demand and supply, energy policies, and energy security in the Republic of Korea. Energy Policy. 2011;39(11):6882–97.

https://www.iea.orgweo. World Energy Outook2017.

Bhutto AW, Bazmi AA, Zahedi G, Klemeš JJ. A review of progress in renewable energy implementation in the Gulf Cooperation Council countries. J Clean Prod. 2014;71:168–80.

Kidnay AJ, Parrish WR, McCartney DG. Fundamentals of natural gas processing. Boca Raton: CRC Press; 2011.

Barclary M, Denton N. Selecting offshore LNG processes. LNG J. 2005;10:34–6.

Elliot D, editor. Benefit of integrating NGL extraction and LNG liquefaction technology. AIChE Spring National Meeting. In: 5th Topical conference on natural gas utilization (TI) session 16c-Gas, Atlanta, USA, 2005; 2005.

He T, Karimi IA, Ju Y. Review on the design and optimization of natural gas liquefaction processes for onshore and offshore applications. Chem Eng Res Des. 2018;132:89–114.

Kuo J, Wang K, Chen C. Pros and cons of different Nitrogen Removal Unit (NRU) technology. J Nat Gas Sci Eng. 2012;7:52–9.

Morosuk T, Tesch S, Hiemann A, Tsatsaronis G, Omar NB. Evaluation of the PRICO liquefaction process using exergy-based methods. J Nat Gas Sci Eng. 2015;27:23–31.

Morosuk T, Tsatsaronis G. Comparative evaluation of LNG–based cogeneration systems using advanced exergetic analysis. Energy. 2011;36(6):3771–8.

Park JH, Khan MS, Andika R, Getu M, Bahadori A, Lee M. Techno-economic evaluation of a novel NGL recovery scheme with nine patented schemes for offshore applications. J Nat Gas Sci Eng. 2015;27:2–17.

Mehrpooya M, Hossieni M, Vatani A. Novel LNG-based integrated process configuration alternatives for coproduction of LNG and NGL. Ind Eng Chem Res. 2014;53(45):17705–21.

Popli S, Rodgers P, Eveloy V. Gas turbine efficiency enhancement using waste heat powered absorption chillers in the oil and gas industry. Appl Therm Eng. 2013;50(1):918–31.

Vatani A, Mehrpooya M, Tirandazi B. A novel process configuration for co-production of NGL and LNG with low energy requirement. Chem Eng Process. 2013;63:16–24.

Wang M, Khalilpour R, Abbas A. Thermodynamic and economic optimization of LNG mixed refrigerant processes. Energy Convers Manag. 2014;88:947–61.

Xu X, Liu J, Jiang C, Cao L. The correlation between mixed refrigerant composition and ambient conditions in the PRICO LNG process. Appl Energy. 2013;102:1127–36.

Hasan MF, Razib MS, Karimi I. Optimization of compressor networks in LNG operations. Computer aided chemical engineering. Amsterdam: Elsevier; 2009. p. 1767–72.

Kalinowski P, Hwang Y, Radermacher R, Al Hashimi S, Rodgers P. Application of waste heat powered absorption refrigeration system to the LNG recovery process. Int J Refrig. 2009;32(4):687–94.

Matjanov E. Gas turbine efficiency enhancement using absorption chiller. Case study for Tashkent CHP. Energy. 2020;192:116625.

Li C, Liu J, Zheng S, Chen X, Li J, Zeng Z. Performance analysis of an improved power generation system utilizing the cold energy of LNG and solar energy. Appl Therm Eng. 2019;159:113937.

Ding H, Sun H, Sun S, Chen C. Analysis and optimisation of a mixed fluid cascade (MFC) process. Cryogenics. 2017;83:35–49.

Piadehrouhi F, Ghorbani B, Miansari M, Mehrpooya M. Development of a new integrated structure for simultaneous generation of power and liquid carbon dioxide using solar dish collectors. Energy. 2019;179:938–59.

Ghorbani B, Mahyari KB, Mehrpooya M, Hamedi M-H. Introducing a hybrid renewable energy system for production of power and fresh water using parabolic trough solar collectors and LNG cold energy recovery. Renew Energy. 2020;148:1227–43.

Mehrpooya M, Ghorbani B, Hosseini SS. Thermodynamic and economic evaluation of a novel concentrated solar power system integrated with absorption refrigeration and desalination cycles. Energy Convers Manag. 2018;175:337–56.

Ashouri M, Vandani AMK, Mehrpooya M, Ahmadi MH, Abdollahpour A. Techno-economic assessment of a Kalina cycle driven by a parabolic Trough solar collector. Energy Convers Manag. 2015;105:1328–39.

Rao W-J, Zhao L-J, Liu C, Zhang M-G. A combined cycle utilizing LNG and low-temperature solar energy. Appl Therm Eng. 2013;60(1–2):51–60.

Javidmehr M, Joda F, Mohammadi A. Thermodynamic and economic analyses and optimization of a multi-generation system composed by a compressed air storage, solar dish collector, micro gas turbine, organic Rankine cycle, and desalination system. Energy Convers Manag. 2018;168:467–81.

Chen Y, Han W, Jin H. Proposal and analysis of a novel heat-driven absorption–compression refrigeration system at low temperatures. Appl Energy. 2017;185:2106–16.

Ghorbani B, Hamedi M-H, Amidpour M, Shirmohammadi R. Implementing absorption refrigeration cycle in lieu of DMR and C3MR cycles in the integrated NGL, LNG and NRU unit. Int J Refrig. 2017;77:20–38.

Nouri M, Miansari M, Ghorbani B. Exergy and economic analyses of a novel hybrid structure for simultaneous production of liquid hydrogen and carbon dioxide using photovoltaic and electrolyzer systems. J Clean Prod. 2020;259:120862.

Mehrpooya M, Ghorbani B, Mousavi SA, Zaitsev A. Proposal and assessment of a new integrated liquefied natural gas generation process with auto–Cascade refrigeration (exergy and economic analyses). Sustain Energy Technol Assess. 2020;40:100728.

Ghorbani B, Shirmohammadi R, Mehrpooya M. A novel energy efficient LNG/NGL recovery process using absorption and mixed refrigerant refrigeration cycles–Economic and exergy analyses. Appl Therm Eng. 2018;132:283–95.

Xu Y, Jiang N, Pan F, Wang Q, Gao Z, Chen G. Comparative study on two low-grade heat driven absorption–compression refrigeration cycles based on energy, exergy, economic and environmental (4E) analyses. Energy Convers Manag. 2017;133:535–47.

Baccioli A, Antonelli M, Desideri U. Dynamic modeling of a solar ORC with compound parabolic collectors: annual production and comparison with steady-state simulation. Energy Convers Manag. 2017;148:708–23.

Bellos E, Tzivanidis C. Multi-objective optimization of a solar driven trigeneration system. Energy. 2018;149:47–62.

Mehrpooya M, Taromi M, Ghorbani B. Thermo-economic assessment and retrofitting of an existing electrical power plant with solar energy under different operational modes and part load conditions. Energy Rep. 2019;5:1137–50.

Kalogirou SA. Solar energy engineering: processes and systems. Cambridge: Academic Press; 2013.

Ghorbani B, Mehrpooya M, Omid E. Hybrid solar liquefied natural gas, post combustion carbon dioxide capture and liquefaction. Energy Convers Manag. 2020;207:112512.

Mehrpooya M, Ghorbani B, Manizadeh A. Cryogenic biogas upgrading process using solar energy (process integration, development, and energy analysis). Energy. 2020;203:117834.

Ghorbani B, Mehrpooya M, Shokri S. Developing an integrated structure for simultaneous generation of power and liquid CO2 using parabolic solar collectors, solid oxide fuel cell, and post-combustion CO2 separation unit. Appl Therm Eng. 2020;179:115687.

Mehrpooya M, Sharifzadeh MMM, Mousavi SA. Evaluation of an optimal integrated design multi-fuel multi-product electrical power plant by energy and exergy analyses. Energy. 2019;169:61–78.

Mohammadi A, Kasaeian A, Pourfayaz F, Ahmadi MH. Thermodynamic analysis of a combined gas turbine, ORC cycle and absorption refrigeration for a CCHP system. Appl Therm Eng. 2017;111:397–406.

Sadaghiani MS, Mehrpooya M. Introducing and energy analysis of a novel cryogenic hydrogen liquefaction process configuration. Int J Hydrog Energy. 2017;42(9):6033–50.

Mehrpooya M, Ghorbani B, Hosseini SS. Developing and exergetic performance assessment of biogas upgrading process driven by flat plate solar collectors coupled with Kalina power cycle. Energy Convers Manag. 2019;181:398–413.

Ghorbani B, Mehrpooya M, Ghasemzadeh H. Investigation of a hybrid water desalination, oxy-fuel power generation and CO2 liquefaction process. Energy. 2018;158.

Ghorbani B, Shirmohammadi R, Mehrpooya M, Hamedi M-H. Structural, operational and economic optimization of cryogenic natural gas plant using NSGAII two-objective genetic algorithm. Energy. 2018;159:410–28.

Ghorbani B, Mehrpooya M, Mousavi SA. Hybrid molten carbonate fuel cell power plant and multiple-effect desalination system. J Clean Prod. 2019;220:1039–51.

Mehrpooya M, Sharifzadeh MMM, Rosen MA. Energy and exergy analyses of a novel power cycle using the cold of LNG (liquefied natural gas) and low-temperature solar energy. Energy. 2016;95:324–45.

Kotas TJ. The exergy method of thermal plant analysis. Amsterdam: Elsevier; 2013.

Ghorbani B, Miansari M, Zendehboudi S, Hamedi M-H. Exergetic and economic evaluation of carbon dioxide liquefaction process in a hybridized system of water desalination, power generation, and liquefied natural gas regasification. Energy Convers Manag. 2020;205:112374.

Mohammadi A, Ahmadi MH, Bidi M, Ghazvini M, Ming T. Exergy and economic analyses of replacing feedwater heaters in a Rankine cycle with parabolic trough collectors. Energy Rep. 2018;4:243–51.

Vatani A, Mehrpooya M, Palizdar A. Energy and exergy analyses of five conventional liquefied natural gas processes. Int J Energy Res. 2014;38(14):1843–63.

Forg W. Liquefaction of natural gas. Google Patents; 1978.

Mehrpooya M, Jarrahian A, Pishvaie MR. Simulation and exergy-method analysis of an industrial refrigeration cycle used in NGL recovery units. Int J Energy Res. 2006;30(15):1336–51.

Mehrpooya M, Vatani A. System and method for recovering natural gas liquids with auto refrigeration system. Google Patents; 2013.

Ebrahimi A, Ziabasharhagh M. Optimal design and integration of a cryogenic Air Separation Unit (ASU) with Liquefied Natural Gas (LNG) as heat sink, thermodynamic and economic analyses. Energy. 2017;126:868–85.

Ebrahimi A, Ghorbani B, Lohrasbi H, Ziabasharhagh M. Novel integrated structure using solar parabolic dish collectors for liquid nitrogen production on offshore gas platforms (exergy and economic analysis). Sustain Energy Technol Assess. 2020;37:100606.

Ebrahimi A, Ghorbani B, Ziabasharhagh M. Pinch and sensitivity analyses of hydrogen liquefaction process in a hybridized system of biomass gasification plant, and cryogenic air separation cycle. J Clean Prod. 2020;258:120548.

Linnhoff B, Hindmarsh E. The pinch design method for heat exchanger networks. Chem Eng Sci. 1983;38(5):745–63.

Alfellag MAA. Modeling and experimental investigation of parabolic trough solar collector. Embry-Riddle Aeronautical University; Master of Science in Mechanical Engineering. 2014.

Ghorbani B, Hamedi M-H, Amidpour M, Mehrpooya M. Cascade refrigeration systems in integrated cryogenic natural gas process (natural gas liquids (NGL), liquefied natural gas (LNG) and nitrogen rejection unit (NRU)). Energy. 2016;115:88–106.

Khan MS, Chaniago YD, Getu M, Lee M. Energy saving opportunities in integrated NGL/LNG schemes exploiting: thermal-coupling common-utilities and process knowledge. Chem Eng Process. 2014;82:54–64.

Ghorbani B, Hamedi M-H, Amidpour M. Development and optimization of an integrated process configuration for natural gas liquefaction (LNG) and natural gas liquids (NGL) recovery with a nitrogen rejection unit (NRU). J Nat Gas Sci Eng. 2016;34:590–603.

Brostow AA, Roberts MJ. Integrated NGL recovery in the production of liquefied natural gas. Google Patents; 2006.

Roberts MJ, Brostow AA. Integrated NGL Recovery And Liquefied Natural Gas Production. Google Patents; 2010.

Ransbarger WL. Intermediate pressure LNG refluxed NGL recovery process. Google Patents; 2006.

Qualls W, Ransbarger W, Huang S, Yao J, Elliot D, Chen J et al. Lng facility with integrated ngl extraction technology for enhanced ngl recovery and product flexibility. Google Patents; 2006.

Cuellar KT, Wilkinson JD, Hudson PHM, Pierce PMC. Co-Producing LNG from Cryogenic NGL Recovery Plants. 81th Annual Convention of the Gas Processors Association. 2002.

Martinez TL, Wilkinson JD, Hudson HM, Cuellar KT. Liquefied natural gas and hydrocarbon gas processing. Google Patents; 2014.

Mak J, Graham C. Configurations and methods of integrated NGL recovery and LNG liquefaction. Google Patents; 2006.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

BG involved in supervision, conceptualization, methodology, investigation, software, validation, original draft. AE took part in conceptualization, methodology, investigation, writing original draft, software, validation. FS participated in methodology, investigation, writing original draft, software, validation. MZ took part in conceptualization, methodology, investigation, methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghorbani, B., Ebrahimi, A., Skandarzadeh, F. et al. Energy, exergy and pinch analyses of an integrated cryogenic natural gas process based on coupling of absorption–compression refrigeration system, organic Rankine cycle and solar parabolic trough collectors. J Therm Anal Calorim 145, 925–953 (2021). https://doi.org/10.1007/s10973-020-10158-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10158-3