Abstract

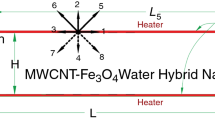

Numerical analysis is carried out on heat transfer performance of industrial-length double-tube heat exchanger, by using hybrid nanofluid as a coolant with the effect of external magnetic field. The double-tube heat exchanger contains two tubes, namely inner and outer, and has lengths of 1.39 m and 1.03 m, respectively. The hot oil passes into the outer tube, and the coolant (hybrid nanofluid) passes into the inner tube. Two types of hybrid nanofluids are used for this investigation: (a) CNT-Al2O3/water and (b) CNT-Fe3O4/water. Volume fraction and Reynolds number are considered as 0.1% to 0.5% and 800 to 2400, respectively. This study is carried out with mixture model wherein the equations are solved with control volume approach combined with second-order upwind scheme. Results indicate that Nusselt number is found higher for CNT-Fe3O4/water hybrid nanofluid in the presence of magnetic field. On using hybrid nanofluid, higher thermal efficiency and better performance index of heat exchanger are achieved. The effectiveness increased nearly ~ 30% at higher Reynolds number with Ha = 20. About 40% better performance index is achieved at lower Reynolds number for CNT-Fe3O4/water when compared with CNT-Al2O3/water hybrid nanofluid. Increment in thermal efficiency of heat exchanger is improved almost 30% by increasing the Reynolds number.

Graphic abstract

Similar content being viewed by others

Abbreviations

- Cp:

-

Heat capacity (J kg−1 K−1)

- D :

-

Diameter (m)

- g :

-

Gravity (m s−2)

- h :

-

Heat transfer coefficient (W m−2 K−1)

- K :

-

Thermal conductivity (W m−1 K−1)

- l :

-

Length (m)

- n :

-

Shape factor (−)

- Nu:

-

Nusselt number (−)

- q :

-

Heat transfer rate (W)

- Re:

-

Reynolds number (−)

- T :

-

Temperature (°C (or) K)

- u,v,w :

-

Velocity components (m s−1)

- U :

-

Overall heat transfer coefficient (W m−2 K−1)

- VG:

-

Viscosity grade (−)

- ∆p :

-

Pressure drop (Pa)

- ∆T :

-

Temperature difference (K)

- bf:

-

Base fluid

- f :

-

Fluid

- hnf:

-

Hybrid nanofluid

- in:

-

Inlet

- nf :

-

Nanofluid

- p :

-

Secondary phase

- s :

-

Nanoparticle (solid particle)

- w :

-

Wall

- \(\rho\) :

-

Density (kg m−3)

- \(\gamma\) :

-

Kinematic viscosity (m2 s−1)

- λ :

-

Mean free path (−)

- \(\beta\) :

-

Thermal expansion coefficient (K−1)

- \(\alpha\) :

-

Thermal diffusivity (m2 s−1)

- \(\varphi\) :

-

Volume concentration (%)

- \(\mu\) :

-

Viscosity (kg m−1 s−1)

References

Xuan Y, Li Q. Heat transfer enhancement of nanofluids. Int J Heat Fluid Flow. 2000;21:58–64.

Vanaki SM, Ganesan P, Mohammed HA. Numerical study of convective heat transfer of nanofluids: a review. Renew Sustain Energy Rev. 2016;54:1212–39.

Nazari S, Toghraie D. Channel with a porous medium numerical simulation of heat transfer and fluid flow of water-CuO nanofluid in a sinusoidal channel with a porous medium. Phys E Low Dimensional Syst Nanostruct. 2016. https://doi.org/10.1016/j.physe.2016.11.035.

Chandrasekar M, Suresh S, Bose AC. Experimental investigations and theoretical determination of thermal conductivity and viscosity of Al2O3/water nanofluid. Exp Therm Fluid Sci. 2010;34:210–6.

Fares M, AL-Mayyahi M, AL-Saad M. Heat transfer analysis of a shell and tube heat exchanger operated with graphene nanofluids. Case Stud Therm Eng. 2020;18:100584.

Ajeel RK, Salim WSI, Sopian K, Yusoff MZ, Hasnan K, Ibrahim A. Turbulent convective heat transfer of silica oxide nanofluid through corrugated channels: an experimental and numerical study. Int J Heat Mass Transf. 2019;145:118806.

Chen Z, Zheng D, Wang J, Chen L, Sundén B. Experimental investigation on heat transfer characteristics of various nanofluids in an indoor electric heater. Renew Energy. 2020;147:1011–8.

Yang L, Du K. Numerical simulation of nanofluid flow and heat transfer in a microchannel: the effect of changing the injection layout arrangement. Int J Mech Sci. 2020;172:105415.

Wang N, Maleki A, Nazari MA, Tlili I, Shadloo MS. Thermal conductivity modeling of nanofluids contain MgO particles by employing different approaches. Symmetry. 2020;12:1–17.

Mabood F, Yusuf TA, Khan WA. Cu–Al2O3–H2O hybrid nanofluid flow with melting heat transfer, irreversibility analysis and nonlinear thermal radiation. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09720-w.

Ilyas SU, Pendyala R, Narahari M. Experimental investigation of natural convection heat transfer characteristics in MWCNT-thermal oil nanofluid. J Therm Anal Calorim. 2019;135(2):1197–209.

Guo W, Li G, Zheng Y, Dong C. The effect of flow pulsation on Al2O3 nanofluids heat transfer behavior in a helical coil: a numerical analysis. Chem Eng Res Des. 2020;156:76–85.

Manay E, Mandev E. Experimental investigation of mixed convection heat transfer of nanofluids in a circular microchannel with different inclination angles. J Therm Anal Calorim. 2019;135:887–900.

Ahmed F, Iqbal M. Numerical simulation of forced convective power law nanofluid through circular annulus sector. J Therm Anal Calorim. 2019;135:861–71.

Mousavi SB, Heyhat MM. Numerical study of heat transfer enhancement from a heated circular cylinder by using nanofluid and transverse oscillation. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7343-3.

Sekrani G, Poncet S, Proulx P. Conjugated heat transfer and entropy generation of Al2O3–water nanofluid flows over a heated wall-mounted obstacle. J Therm Anal Calomet. 2018. https://doi.org/10.1007/s10973-018-7349-x.

Maleki A, Elahi M, Assad MEH, Alhuyi M, Mostafa N, et al. Thermal conductivity modeling of nanofluids with ZnO particles by using approaches based on artificial neural network and MARS. J Therm Anal Calorim. 2020;1:0123456789.

Water AO, Flow N. SS symmetry numerical investigation of forced convective heat transfer and performance evaluation criterion of Al2O3/water nanofluid flow inside an axisymmetric microchannel. Symmetry. 2020;120(12):1–13.

Komeilibirjandi A, Hossein A, Akbar R. Thermal conductivity prediction of nanofluids containing CuO nanoparticles by using correlation and artificial neural network. J Therm Anal Calorim. 2019;139:0123456789.

Maleki A, Haghighi A, Irandoost M, Zahra S. Applying different types of artificial neural network for modeling thermal conductivity of nanofluids containing silica particles. J Therm Anal Calorim. 2020;1:0123456789.

Zhang Y, Jiang J, Bai Y. MHD flow and heat transfer analysis of fractional oldroyd-B nanofluid between two coaxial cylinders. Comput Math Appl. 2019;78(10):3408–21.

Izadi A, Siavashi M, Rasam H, Xiong Q. MHD enhanced nanofluid mediated heat transfer in porous metal for CPU cooling. Appl Therm Eng. 2020;168:114843.

Vinita V, Poply V. Materials today: proceedings Impact of outer velocity MHD slip flow and heat transfer of nanofluid past a stretching cylinder. Mater Today Proc. 2019;26:3429–35.

Singh SK, Sarkar J. Improving hydrothermal performance of hybrid nanofluid in double tube heat exchanger using tapered wire coil turbulator. Adv Powder Technol. 2020. https://doi.org/10.1016/j.apt.2020.03.002.

Qi C, Luo T, Liu M, Fan F, Yan Y. Experimental study on the flow and heat transfer characteristics of nanofluids in double-tube heat exchangers based on thermal efficiency assessment. Energy Convers Manag. 2019;197:111877.

Karimi A, Al-rashed AAAA, Afrand M, Mahian O, Wongwises S, Shahsavar A. International journal of mechanical sciences the effects of tape insert material on the flow and heat transfer in a nanofluid-based double tube heat exchanger: two-phase mixture model. Int J Mech Sci. 2019;156:397–409.

Moya-rico JD, Molina AE, Belmonte JF, Tendero JIC. Experimental characterization of a double tube heat exchanger with inserted twisted tape elements. Appl Therm Eng. 2020;174:115234.

Dogonchi AS, Ganji DD. Impact of Cattaneo–Christov heat flux on MHD nanofluid flow and heat transfer between parallel plates considering thermal radiation effect. J Taiwan Inst Chem Eng. 2017;80:1–12.

Souayeh B, Reddy MG, Sreenivasulu P, Poornima T, Rahimi-gorji M, Alari IM. Comparative analysis on non-linear radiative heat transfer on MHD Casson nano fluid past a thin needle. J Mol Liq. 2019;284:163–74.

Shah Z, Alzahrani EO, Dawar A, Alghamdi W. Entropy generation in MHD second-grade nanofluid thin film flow containing CNTs with Cattaneo-Christov heat flux model past an unsteady stretching sheet. Appl Sci. 2020;2720:1–24.

Jawad M, Shah Z, Islam S, Bonyah E, Khan AZ. Darcy–Forchheimer flow of MHD nanofluid thin film flow with Joule dissipation and Navier’s partial slip. J Phys Commun. 2018;2:115014.

Khan NS, Shah Z, Shutaywi M, Kumam P. A comprehensive study to the assessment of Arrhenius activation energy and binary chemical reaction in swirling flow. Sci Rep. 2020;10:1–21.

Bahiraei M, Akbar A. Thermohydraulic performance analysis of a spiral heat exchanger operated with water–alumina nano fluid: effects of geometry and adding nanoparticles. Energy Convers Manag. 2018;170:62–72.

Bahiraei M, Kiani H, Reza M. Effect of employing a new biological nano fluid containing functionalized graphene nanoplatelets on thermal and hydraulic characteristics of a spiral heat exchanger. Energy Convers Manag. 2019;180:72–82.

Bahiraei M, Jamshidmofid M, Amani M, Barzegarian R. Investigating exergy destruction and entropy generation for flow of a new nanofluid containing graphene–silver nanocomposite in a micro heat exchanger considering viscous dissipation. Powder Technol. 2018;336:298–310.

Iacobazzi F. A critical analysis of clustering phenomenon in Al2O3 nanofluids. J Therm Anal Calorim. 2018;135:371–7.

Milanese M, Iacobazzi F, Colangelo G, De RA. An investigation of layering phenomenon at the liquid–solid interface in Cu and CuO based nanofluids. Int J Heat Mass Transf. 2016;103:564–71.

Ahmadi MH, Ahmadi M, Maleki A, Pourfayaz F. Exergetic sustainability evaluation and multi-objective optimization of performance of an irreversible nanoscale Stirling refrigeration cycle operating with Maxwell–Boltzmann gas. Renew Sust Energ Rev. 2017;78:80–92.

Zhang G, Shi Y, Maleki A, Rosen MA. Optimal location and size of a grid-independent solar/hydrogen system for rural areas using an eicient heuristic approach. Renew Energ. 2020;156:1203–14.

Maleki A. Design and optimization of autonomous solar-wind-reverse osmosis desalination systems coupling battery and hydrogen energy storage by an improved bee algorithm. Desalination. 2018;435:221–34.

Zhang W, Maleki A, Rosen MA. A heuristic-based approach for optimizing a small independent solar and wind hybrid power scheme incorporating load forecasting. J Clean Prod. 2019;241:117920.

Cai W, Li X, Maleki A, Pourfayaz F, Rosen MA, Nazari MA. Optimal sizing and location based on economic parameters for an off-grid application of a hybrid system with photovoltaic, battery and diesel technology. Energy. 2020;201:117480.

Maleki A, Alhuyi M, Pourfayaz F. Harmony search optimization for optimum sizing of hybrid solar schemes based on battery storage unit. Energy Rep. 2020. https://doi.org/10.1016/j.egyr.2020.03.014.

Loganathan K, Mohana K, Mohanraj M, Sakthivel P, Rajan S. Impact of third grade nanofluid flow across a convective surface in the presence of inclined Lorentz force: an approach to entropy optimization. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09751-3.

Kaska SA, Khalefa RA, Hussein AM. Hybrid nanofluid to enhance heat transfer under turbulent flow in a flat tube. Case Stud Therm Eng. 2019;13:4–13.

Huminic G, Huminic A. Hybrid nanofluids for heat transfer applications—a state-of-the-art review. Int J Heat Mass Transf. 2018;125:82–103.

Yıldız Ç, Arıcı M, Karabay H. Comparison of a theoretical and experimental thermal conductivity model on the heat transfer performance of Al2O3–SiO2/water hybrid-nanofluid. Int J Heat Mass Transf. 2019;140:598–605.

Dalkılıç AS, Türk OA, Mercan H, Nakkaew S, Wongwises S. An experimental investigation on heat transfer characteristics of graphite-SiO2/water hybrid nanofluid flow in horizontal tube with various quad-channel twisted tape inserts. Int Commun Heat Mass Transf. 2019;107:1–13.

Waini I, Ishak A, Pop I. Transpiration effects on hybrid nanofluid flow and heat transfer over a stretching/shrinking sheet with uniform shear flow. Alex Eng J. 2020;59:91–9.

Sun B, Zhang Y, Yang D, Li H. Experimental study on heat transfer characteristics of hybrid nanofluid impinging jets. Appl Therm Eng. 2019;151:556–66.

Khashi’ie NS, Arifin NM, Nazar R, Hafidzuddin EH, Wahi N, Pop I. Magnetohydrodynamics (MHD) axisymmetric flow and heat transfer of a hybrid nanofluid past a radially permeable stretching/shrinking sheet with Joule heating. Chin J Phys. 2020;64:251–63.

Hussanan A, Qasim M, Chen ZM. Heat transfer enhancement in sodium alginate based magnetic and non-magnetic nanoparticles mixture hybrid nanofluid. Phys A Stat Mech Appl. 2020. https://doi.org/10.1016/j.physa.2019.123957.

Huminic G, Huminic A. Heat transfer capability of the hybrid nanofluids for heat transfer applications. J Mol Liq. 2018;272:857–70.

Bahiraei M, Mazaheri N, Rizehvandi A. Application of a hybrid nanofluid containing graphene nanoplatelet–platinum composite powder in a triple-tube heat exchanger equipped with inserted ribs. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2018.12.072.

Ashorynejad HR, Shahriari A. MHD natural convection of hybrid nanofluid in an open wavy cavity. Results Phys. 2018;9:440–55.

Ma Y, Mohebbi R, Rashidi MM, Yang Z. MHD convective heat transfer of Ag–MgO/water hybrid nanofluid in a channel with active heaters and coolers. Int J Heat Mass Transf. 2019;137:714–26.

Abraham L, Thomas T, Pichumani M. Journal of Colloid and Interface Science Correlation of micellar aggregation—complexation regimes to discern stability of micellar structure and nano-encapsulation. J Colloid Interface Sci. 2019;547:234–44.

Chamkha AJ. Magnetohydrodynamic natural convection heat transfer of hybrid nanofluid in a square enclosure in the presence of a wavy circular conductive cylinder. J Therm Sci Eng Appl. 2020;12:1–10.

Olatundun AT, Makinde OD. Analysis of blasius flow of hybrid nanofluids over a convectively heated surface. Defect Diffus Forum. 2017;377:29–41.

Saba F, Ahmed N, Khan U, Mohyud-din ST. A novel coupling of (CNT-Fe3O4/H2O) hybrid nanofluid for improvements in heat transfer for flow in an asymmetric channel with dilating/squeezing walls. Int J Heat Mass Transf. 2019;136:186–95.

Anitha S, Thomas T, Parthiban V, Pichumani M. What dominates heat transfer performance of hybrid nanofluid in single pass shell and tube heat exchanger? Adv Powder Technol. 2019;30(12):3107–17.

Rosdzimin M, Rahman A, Yuen K, Azam L, Idris C, Rashdan M, et al. Numerical analysis of the forced convective heat transfer on Al2O3–Cu/water hybrid nanofluid. Heat Mass Transf. 2016;53:1835–42.

Li F, Zhu W, He H. Numerical optimization on microchannel flow and heat transfer performance based on field synergy principle. Int J Heat Mass Transf. 2019;130:375–85.

Yin Z, Bao F, Tu C, Hua Y, Tian R. Numerical and experimental studies of heat and flow characteristics in a laminar pipe flow of nanofluid. J Exp Nanosci. 2017. https://doi.org/10.1080/17458080.2017.1413599.

Chen L, Cheng M, Yang D, Yang L. Enhanced thermal conductivity of nanofluid by synergistic effect of multi-walled carbon nanotubes and Fe2O3 nanoparticles. Appl Mech Mater. 2014;549:118–23.

Acknowledgements

We highly acknowledge the Management of Sri Ramakrishna Engineering College, Coimbatore, India. This research work is funded by Department of science and Technology-WOS (A) (SR/WOSA/PM-86/2017). Also this work is partly supported by Government of India-DST INSPIRE project 04/2013/000209.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Anitha, S., Loganathan, K. & Pichumani, M. Approaches for modelling of industrial energy systems: correlation of heat transfer characteristics between magnetohydrodynamics hybrid nanofluids and performance analysis of industrial length-scale heat exchanger. J Therm Anal Calorim 144, 1783–1798 (2021). https://doi.org/10.1007/s10973-020-10072-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10072-8