Abstract

With the rapid increasing heat fluxes released from micro electronic devices, thermal management of electric components faces huge challenge. High working temperature generated by the chip will directly affect its performance. It is essential to develop advanced model to enhance heat transfer. In this study, a new microchannel heat sinks with impinging jets and dimples (MHSIJD) model with side outlets was proposed. Computational fluid dynamics simulation methodology with RNG k–ε turbulence model was used to investigate the performance of MHSIJD with side outlets. Valuation indices including thermal capability, pump consumption and overall performance were analyzed. Three models were compared with basic model (MHSIJD without side outlets): the cross section of the side outlet was set as 0.2 × 0.2 mm (Case 1), 0.4 × 0.4 mm (Case 2), and 0.6 × 0.6 mm (Case 3). The results showed that: (1) the MHSIJD with side outlets performs better heat transfer characteristic due to the alleviation of drift phenomenon. The heat transfer capacity can be increased by up to 17.51%; (2) the MHSIJD with side outlets exhibits a lower pressure drop, which can be reduced up to 22.39%; and (3) the overall performance of MHSIJD with side outlets is better due to its higher cooling efficiency and lower pump consumption.

Similar content being viewed by others

Abbreviations

- C 1ε :

-

Empirical constants 1.42

- C 2ε :

-

Empirical constants 1.68

- C μ :

-

Empirical constants 0.085

- C p :

-

Isobaric specific heat (J K−1 kg−1)

- f :

-

Acceleration of gravity (m s−2)

- G k :

-

Turbulent kinetic energy caused by the average velocity gradient

- H :

-

Heat sink height (mm)

- H 1 :

-

Jet height (mm)

- H 2 :

-

Channel height (mm)

- H 3 :

-

Height of side outlet in cross section (mm)

- h :

-

Convective heat transfer coefficient (W m−2 K−1)

- k :

-

Turbulent kinetic energy

- k f :

-

Thermal conductivity of the fluid (W m−1 K−1)

- L :

-

Heat sink length (mm)

- L 1 :

-

Length of jet in cross section (mm)

- L 2 :

-

Spacing between jets (mm)

- \(\overline{Nu}\) :

-

Nusselt number (−)

- P :

-

Total pressure (Pa)

- \(Pr_{\text{T}}\) :

-

Turbulent Prandtl number

- \(\hat{q}\) :

-

Heat flux (W m−2)

- R :

-

Radius of dimple (mm)

- Re :

-

Reynolds number (−)

- S :

-

Deformation rate tensor

- t :

-

Time—for unsteady items (s)

- T :

-

Temperature (K)

- u :

-

Velocity (m s−1)

- W :

-

Heat sink width (mm)

- W 1 :

-

Channel width (mm)

- x, y, z :

-

Cartesian coordinates (−)

- α k :

-

Inverse effective Prandtl numbers for k

- α ε :

-

Inverse effective Prandtl numbers for ε

- β :

-

Volume coefficient of expansion (1 K−1)

- δ :

-

Kronecker delta

- ε :

-

Turbulent dissipation rate

- μ :

-

Dynamic viscosity (Pa s)

- μ t :

-

Turbulent viscosity

- τ :

-

Thear stress caused by viscosity (N m−2)

- ρ :

-

Density (kg m−3)

- ΔP :

-

Pressure drop (Pa)

- f:

-

Fluid

- in:

-

Impinging jet inlet

- out:

-

Channel outlet

- i, j :

-

Any direction of x, y and z

- w :

-

Cooled surface

- \(\bar{a}\) :

-

Time average of a

- T :

-

Temperature

References

Guo ZY. The frontier of international heat transfer research—fine-scale heat transfer. Adv Mech. 2000;30(1):1–6.

Dewan A, Srivastava P. A review of heat transfer enhancement through flow disruption in a microchannel. J Therm Sci. 2015;24(3):203–14.

Liou TM, Wei TC, Wang CS. Investigation of nanofluids on heat transfer enhancement in a louvered microchannel with lattice Boltzmann method. J Therm Anal Calorim. 2019;135(1):751–62.

Tuckerman DB, Pease RFW. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 1981;2(5):126–9.

Drummond KP, Doosan B, Sinanis MD, Janes DB, Peroulis D, Weibel JA, Garimella SV. Characterization of hierarchical manifold microchannel heat sink arrays under simultaneous background and hotspot heating conditions. Int J Heat Mass Transf. 2018;126:1289–301.

Li P, Luo Y, Zhang D, Xie YH. Flow and heat transfer characteristics and optimization study on the water-cooled microchannel heat sinks with dimple and pin-fin. Int J Heat Mass Transf. 2018;119:152–62.

Alipour Lalami A, Hassanzadeh Afrouzi H, Moshfegh A. Investigation of MHD effect on nanofluid heat transfer in microchannels. J Therm Anal Calorim. 2019;136(5):1959–75.

Manay E, Mandev E. Experimental investigation of mixed convection heat transfer of nanofluids in a circular microchannel with different inclination angles. J Therm Anal Calorim. 2019;135(2):887–900. https://doi.org/10.1007/s10973-018-7463-9.

Khodabandeh E, Rozati SA, Joshaghani M, Akbari OA, Akbari S, Toghraie D. Thermal performance improvement in water nanofluid/GNP–SDBS in novel design of double-layer microchannel heat sink with sinusoidal cavities and rectangular ribs. J Therm Anal Calorim. 2019;136:1333–45.

Guthrie DGP, Torabi M, Karimi N. Energetic and entropic analyses of double-diffusive, forced convection heat and mass transfer in microreactors assisted with nanofluid. J Therm Anal Calorim. 2019;137(2):637–58. https://doi.org/10.1007/s10973-018-7959-3.

Toghraie D, Abdollah MMD, Pourfattah F, Akbari OA, Ruhani B. Numerical investigation of flow and heat transfer characteristics in smooth, sinusoidal and zigzag-shaped microchannel with and without nanofluid. J Therm Anal Calorim. 2017;131(5):1–10.

Liou TM, Wei TC, Wang CS. Investigation of nanofluids on heat transfer enhancement in a louvered microchannel with lattice Boltzmann method. J Therm Anal Calorim. 2019;135(1):751–62.

Heydari A, Akbari OA, Safaei MR, Derakhshani M, Alrashed AAAA, Mashayekhi R, Shabani GAS, Zarringhalam M, Nguyen TK. The effect of attack angle of triangular ribs on heat transfer of nanofluids in a microchannel. J Therm Anal Calorim. 2018;131(3):2893–913.

Akbari OA, Khodabandeh E, Kahbandeh F, Toghraie D, Khalili M. Numerical investigation of heat transfer of nanofluid flow through a microchannel with heat sinks and sinusoidal cavities by using novel nozzle structure. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08227-3.

Mohammadi M, Abadeh A, Reza NF, Mohammad PF. An optimization of heat transfer of nanofluid flow in a helically coiled pipe using Taguchi method. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08167-y.

Abazar A, Majid M, Mohammad PF. Experimental investigation on heat transfer enhancement for a ferrofluid in a helically coiled pipe under constant magnetic field. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7478-2.

Li J, Peterson GP, Cheng P. Three-dimensional analysis of heat transfer in a micro-heat sink with single phase flow. Int J Heat Mass Transf. 2004;47(19):4215–31.

Wu HY, Cheng P. An experimental study of convective heat transfer in silicon microchannels with different surface conditions. Int J Heat Mass Transf. 2003;46(14):2547–56.

Li Z, Tao WQ, He YL. A numerical study of laminar convective heat transfer in microchannel with non-circular cross-section. Int J Therm Sci. 2006;45(12):1140–8.

Chen Y, Zhang C, Shi M, Wu J. Three-dimensional numerical simulation of heat and fluid flow in noncircular microchannel heat sinks. Int Commun Heat Mass Transf. 2009;36(9):917–20.

Gunnasegaran P, Mohammed HA, Shuaib NH, Saidur R. The effect of geometrical parameters on heat transfer characteristics of microchannels heat sink with different shapes. Int Commun Heat Mass Transf. 2010;37(8):1078–86.

Wang H, Chen Z, Gao J. Influence of geometric parameters on flow and heat transfer performance of micro-channel heat sinks. Appl Therm Eng. 2016;107:870–9.

Xie XL, Liu ZJ, He YL, Tao WQ. Numerical study of laminar heat transfer and pressure drop characteristics in a water-cooled minichannel heat sink. Appl Therm Eng. 2009;29(1):64–74.

Cao H, Chen G. Optimization design of microchannel heat sink geometry for high power laser mirror. Appl Therm Eng. 2010;30(13):1644–51.

Utriainen E, Sundén B. Numerical analysis of a primary surface trapezoidal cross wavy duct. Int J Numer Methods Heat Fluid Flow. 2000;10(6):634–48.

Mohammed HA, Gunnasegaran P, Shuaib NH. Numerical simulation of heat transfer enhancement in wavy microchannel heat sink. Int Commun Heat Mass Transf. 2011;38(1):63–8.

Gong L, Kota K, Tao W, Joshi Y. Parametric numerical study of flow and heat transfer in microchannels with wavy walls. J Heat Transf Trans ASME. 2011;133(5):746.

Lee DY, Vafai K. Comparative analysis of jet impingement and microchannel cooling for high heat flux applications. Int J Heat Mass Transf. 1999;42(9):1555–68.

Ming TZ, Ding Y, Gui JL, Tao YX. Transient thermal behavior of a microchannel heat sink with multiple impinging jets. J Zhejiang Universityence A. 2015;16(11):894–909.

Sung MK, Mudawar I. Single-phase and two-phase cooling using hybrid micro-channel/slot-jet module. Int J Heat Mass Transf. 2008;51(15):3825–39.

Sung MK, Mudawar I. Effects of jet pattern on two-phase performance of hybrid micro-channel/micro-circular-jet-impingement thermal management scheme. Int J Heat Mass Transf. 2009;52(13):3364–72.

Sung MK, Mudawar I. CHF determination for high-heat flux phase change cooling system incorporating both micro-channel flow and jet impingement. Int J Heat Mass Transf. 2009;52(3):610–9.

Jang SP, Kim SJ, Paik KW. Experimental investigation of thermal characteristics for a microchannel heat sink subject to an impinging jet, using a micro-thermal sensor array. Sens Actuators, A. 2003;105(2):211–24.

Shafeie H, Abouali O, Jafarpur K, Ahmadi G. Numerical study of heat transfer performance of single-phase heat sinks with micro pin-fin structures. Appl Therm Eng. 2013;58(1–2):68–76.

Mishra C, Peles Y. Laminar flow across a bank of low aspect ratio micro pin fins. J Fluids Eng. 2005;127(3):419–30.

Jin Z, Huang S, Liang G, Huang Z. Numerical study and optimizing on micro square pin-fin heat sink for electronic cooling. Appl Therm Eng. 2016;93:1347–59.

Hua J, Li G, Zhao X, Li Q, Hu J. Study on the flow resistance performance of fluid cross various shapes of micro-scale pin fin. Appl Therm Eng. 2016;107:768–75.

Hong F, Cheng P. Three dimensional numerical analyses and optimization of offset strip-fin microchannel heat sinks. Int Commun Heat Mass Transf. 2009;36(7):651–6.

Moores KA, Kim J, Joshi YK. Heat transfer and fluid flow in shrouded pin fin arrays with and without tip clearance. Int J Heat Mass Transf. 2009;52(25):5978–89.

Reyes M, Arias JR, Velazquez A, Vega JM. Experimental study of heat transfer and pressure drop in micro-channel based heat sinks with tip clearance. Appl Therm Eng. 2011;31(5):887–93.

Mei D, Lou X, Miao Q, Yao Z, Liang L, Chen Z. Effect of tip clearance on the heat transfer and pressure drop performance in the micro-reactor with micro-pin-fin arrays at low Reynolds number. Int J Heat Mass Transf. 2014;70(2):709–18.

Liu W, Liu P, Wang JB, Zheng NB, Liu ZC. Exergy destruction minimization: a principle to convective heat transfer enhancement. Int J Heat Mass Transf. 2018;122:11–21.

Xu M, Lu H, Gong L, Chai JC, Duan X. Parametric numerical study of the flow and heat transfer in microchannel with dimples. Int Commun Heat Mass Transf. 2016;76(5):348–57.

Lan J, Xie Y, Zhang D. Flow and heat transfer in microchannels with dimples and protrusions. J Heat Transf Trans ASME. 2012;134(2):021901.

Bi C, Tang GH, Tao WQ. Heat transfer enhancement in mini-channel heat sinks with dimples and cylindrical grooves. Appl Therm Eng. 2013;55(1–2):121–32.

Li P, Zhang D, Xie Y. Heat transfer and flow analysis of Al2O3–water nanofluids in microchannel with dimple and protrusion. Int J Heat Mass Transf. 2014;73(73):456–67.

Li P, Xie Y, Zhang D, Xie G. Heat transfer enhancement and entropy generation of nanofluids laminar convection in microchannels with flow control devices. Entropy. 2016;18(4):134.

Li P, Zhang D, Xie Y, Xie G. Flow structure and heat transfer of non-Newtonian fluids in microchannel heat sinks with dimples and protrusions. Appl Therm Eng. 2016;94:50–8.

Chang SW, Chiou SF, Chang SF. Heat transfer of impinging jet array over concave-dimpled surface with applications to cooling of electronic chipsets. Exp Thermal Fluid Sci. 2007;31(7):625–40.

Kanokjaruvijit K, Martinezbotas RF. Parametric effects on heat transfer of impingement on dimpled surface. J Turbomach. 2005;127(2):77–88.

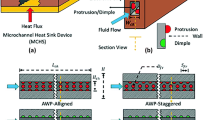

Huang X, Yang W, Ming T, Shen W, Yu X. Heat transfer enhancement on a microchannel heat sink with impinging jets and dimples. Int J Heat Mass Transf. 2017;112:113–24.

Ming T, Cai C, Yang W, Shen W, Feng W, Zhou N. optimization of dimples in microchannel heat sink with impinging jets-part B: the influences of dimple height and arrangement. J Therm Sci. 2018;14:1–10.

Ming T, Cai C, Yang W, Shen W, Gan T. Optimization of dimples in microchannel heat sink with impinging jets-part A: mathematical model and the influence of dimple radius. J Therm Sci. 2018;27(3):195–202.

Ming T, Peng C, Gui J, Tao Y. Analysis on the hydraulic and thermal performances of a microchannel heat sink with extended-nozzle impinging jets. Heat Transf Res. 2016;48(10):893–914.

Li CG, Zhou JM. Experimental and numerical simulation study of heat transfer due to confined impinging circular jet. Chem Eng Technol. 2010;30(11):1355–61.

El-Gabry LA, Kaminski DA. Experimental investigation of local heat transfer distribution on smooth and roughened surfaces under an array of angled impinging jets. J Turbomach Trans ASME. 2005;127(3):532–44. https://doi.org/10.1115/1.1861918.

Acknowledgements

This study is financially supported by the National Natural Science Foundation of China (Grant No. 51778511), the Hubei Provincial Natural Science Foundation of China (Grant No. 2018CFA029), and the Key Project of ESI Discipline Development of Wuhan University of Technology (WUT Grant No. 2017001).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gan, T., Ming, T., Fang, W. et al. Heat transfer enhancement of a microchannel heat sink with the combination of impinging jets, dimples, and side outlets. J Therm Anal Calorim 141, 45–56 (2020). https://doi.org/10.1007/s10973-019-08754-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08754-z