Abstract

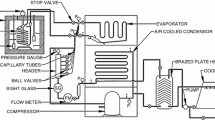

Domestic refrigerator is one of the major energy-consuming appliances, and the enhancement of its energy efficiency plays a vital role in implementing the energy conservation policies and green building concepts in residential sector. The major strategies used to improve the performance of domestic refrigerators are the replacement of existing components, use of alternative refrigerants and the reduction in condensing pressure. Therefore, in this work, the conventional air-cooled condenser has been replaced with water-cooled condensers such as shell-and-coil and brazed-plate heat exchangers to maintain a low compression ratio and condensing pressure. The performance of a domestic refrigeration system retrofitted with water-cooled condensers has been studied using experimental methods. The result showed that the system with water-cooled condensers reduces the pull-down time and the per day energy consumption by 70% and 3.5%, respectively. Moreover, the proposed system can improve the COP and exergy efficiency by 6.4% and 4.9%, respectively. Compared to shell-and-coil heat exchanger, the system with brazed-plate heat exchanger can reduce irreversibility and TEWI by 3.9% and 3.7%, respectively. In this study, the system with brazed-plate heat exchanger showed better performance than the shell-and-coil heat exchanger for all operating conditions.

Similar content being viewed by others

References

IEA. World Energy Outlook 2010. International Energy Agency.Paris.IndiaStat.com. India Statistical Information Database. Delhi; 2010.

van Ruijven BJ, van Vuuren DP, de Vries BJM, Isaac M, van der Sluijs JP, Lucas PL, Balachandra P. Model projections for household energy use in India. Energy Policy. 2011;2011(39):7747–61.

Geppert J, Stamminger R. Analysis of effecting factors on domestic refrigerator’s energy consumption in use. Energy Convers Manag. 2013;76:794–800.

Jones RV, Fuertes A, Lomas KJ. The socio-economic, dwelling and appliance related factors affecting electricity consumption in domestic buildings. Renew Sustain Energy Rev. 2015;43:901–17.

McNeil, MA. Progress towards managing residential electricity demand: impacts of standards and labeling for refrigerators and air conditioners in India. In: 5th international conference on energy efficiency on domestic appliances and lighting EEDAL, Berlin, Germany; 2009.

Yu H, Pan SY, Tang BJ, Mi ZF, Zhang Y, Wei Y-M. Urban energy consumption and CO2 emissions in Beijing: current and future. Energ Effic. 2015;8:527–43.

Raja B, Santhappan SJ, Dhasan LM. Heat transfer correlation for a refrigerant mixture in a vertical helical coil evaporator. Therm Sci. 2009;13:197–206.

Mohanraj M, Jayaraj S, Muraleedharan C, Chandrasekar P. Experimental investigation of R290/R600a mixture as an alternative to R134a in a domestic refrigerator. Int J Therm Sci. 2009;48:1036–42.

Ayub ZH. Plate heat exchanger literature survey and new heat transfer and pressure drop correlations for refrigerant evaporators. Tex Heat Transf Eng. 2003;24:3–16.

Sonnenrein G, Elsner A, Baumhogger E, Morbach A, Fieback K, Vrabec J. Reducing the power consumption of household refrigerators through the integration of latent heat storage elements in wire-and tube condensers. Int J Refrig. 2015;51:154–60.

Zhang Z, Huang D, Zhao R, Leng Y. Effect of airflow field optimization around spiral wire-on-tube condenser on a frost-free refrigerator performance. Appl Therm Eng. 2017;114:785–92.

Gupta JK, Gopal MR. Modeling of hot-wall condensers for domestic refrigerators. Int J Refrig. 2008;31:979–88.

Bansal PK, Chin TC. Design and modelling of hot-wall condensers in domestic refrigerators. Appl Therm Eng. 2002;22:1601–17.

Hosoz M, Kilicarslan A. Performance evaluations of refrigeration systems with air-cooled, water-cooled and evaporative condensers. Int J Energy Res. 2004;28:683–96.

Li Y, Wua J, Shiochi S. Modelling and energy simulation of the variable refrigerant flow air conditioning system with water-cooled condenser under cooling conditions. Energy Build. 2009;41:949–57.

Raveendran PS, Sekhar SJ. Performance studies on a domestic refrigerators retrofitted with building-integrated water-cooled condenser. Energy Build. 2017;134:1–10.

Gupta A, Kumar R, Gupta A. Condensation of R-134a inside a helically coiled tube-in-shell heat exchanger. Exp Therm Fluid Sci. 2014;54:279–89.

ASHRAE Handbook. HVAC systems and equipment. Atlanta: ASHRAE. Inc; 2008.

Raveendran PS, Sekhar SJ. Experimental studies on domestic refrigeration system with brazed plate heat exchanger as condenser. J Mech Sci Technol. 2016;30:2865–71.

Longo GA. Refrigerant R134a condensation heat transfer and pressure drop inside a small brazed plate heat exchanger. Int J Refrig. 2008;31:780–9.

Jia J, Lee WL. Applying storage-enhanced heat recovery room air-conditioner (SEHRAC) for domestic water heating in residential buildings in Hong Kong. Energy Build. 2014;78:132–42.

de Marchi Neto IM, Padilha A, Scalon VL. Refrigerator COP with thermal storage. Appl Therm Eng. 2009;29:2358–64.

ISO, International Standard Organization, International Standard-8187, Household refrigerating appliances (refrigerators/freezers) characteristic and test methods, International Organization for Standardization, Switzerland; 1991.

Holman JP. Experimental methods for engineers. 7th ed. New York: McGraw Hill Publishers; 2000.

Raveendran PS, Sekhar SJ. Exergy analysis on domestic refrigeration system with brazed plate heat exchanger as condenser. J Therm Anal Calorim. 2017;127:2439–46.

Saravanakumar R, Selladurai V. Exergy analysis of a domestic refrigerator using eco-friendly R290/R600a refrigerant mixture as an alternative to R134a. J Therm Anal Calorim. 2014;115:933–40.

Anand S, Tyagi SK. Exergy analysis and experimental study of a vapour compression refrigeration cycle. J Therm Anal Calorim. 2012;110:961–71.

Prabakaran R, Lal DM. A novel exergy based charge optimisation for a mobile air conditioning system. J Therm Anal Calorim. 2018;132:1–12.

Lemmon EW, Huber ML, McLinden MO. Reference fluid thermodynamic and transport properties (REFPROP), Version 9.1.in NIST Standard Reference Database 23. Gaithersburg: National Institute of Standards and Technology; 2007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Raveendran, P.S., Sekhar, S.J. Investigation on the energy and exergy efficiencies of a domestic refrigerator retrofitted with water-cooled condensers of shell-and-coil and brazed-plate heat exchangers. J Therm Anal Calorim 136, 381–388 (2019). https://doi.org/10.1007/s10973-018-7742-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7742-5