Abstract

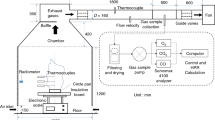

In this study, a series of ethanol–water mixture and Chinese liquor combustion experiments were conducted using an ISO5660-1 cone calorimeter and an automatic flash point tester. The main purpose was to obtain key fire parameter data, including the burning duration, mass loss rate, mass loss rate per unit area, heat release rate per unit area, CO and CO2 volume fraction, CO2/CO ratio and closed-cup flash point. At the same time, the experimental differences between Chinese liquor and ethanol–water mixture were analyzed. Also, the fire risk classification was discussed based on the code of GB 50016-2014. When the ethanol volume fraction of Chinese liquor is greater than 34.8 vol%, the fire risk is the most dangerous level, Class I. While the critical ethanol volume fraction of ethanol–water mixture is 38.9 vol%, it needs to pay more attention to the fire safety of Chinese liquor storage and usage when the ethanol volume fraction is generally from 30 to 65 vol%.

Similar content being viewed by others

References

Mandelbaum DG. Alcohol and culture. Curr Anthropol. 1965;6(3):281–93.

Center for Chemical Process Safety. Guidelines for engineering design for process safety. 2nd ed. New York: American Institute of Chemical Engineers; 1993.

Guangyuan J, Zhu Y, Yan X. Mystery behind Chinese liquor fermentation. Trends Food Sci Technol. 2017;63:18–28.

Xiaowei Z, Han B. Baijiu, Chinese liquor: history, classification and manufacture. J Ethnic Foods. 2016;3(1):19–25.

Turner C. How much alcohol is in a ‘standard drink’? An analysis of 125 studies. Br J Addict. 1990;85(9):1171–5.

http://www.chinadaily.com.cn/life/2010-10/27/content_11692216.htm. Accessed 3 Mar 2018.

http://www.chinatraveldepot.com/C173-Chinese-Alcohol. Accessed 3 Mar 2018.

Song X. A discussion on the fire and explosion protection design of liquor factories. Master thesis. Chongqing University; 2005.

http://news.cnr.cn/native/gd/20160519/t20160519_522182613.shtml. Accessed 3 Mar 2018.

Yunlun Y. Discussion on the static hazard of wine with high spirit—cause determination for“8· 4”wine tank explosion in gongque wine factory of Luzhou. Fire Sci Technol. 2006;25(3):407–10.

GB 50016-2014. Code for fire protection design of building. Beijing: Ministry of Construction of China; 2014.

Hurley MJ, et al. SFPE handbook of fire protection engineering. New York: Springer; 2015.

Lyondell Chemical Company. Ethyl alcohol handbook. 6th ed. Houston: Lyondell Chemical Company; 2003.

Hakkarainen T, Korhonen T, Vaari J. Heat release characteristics of ethanol-water mixtures: small-scale experiments. Fire Saf J. 2017;91:174–81.

Fischer SJ, Hardouin-Duparc B, Grosshandler WL. The structure and radiation of an ethanol pool fire. Combust Flame. 1987;3:291–306.

Babrauskas V. Heat release rates. In: SFPE handbook of fire protection engineering. New York: Springer; 2015.

Degroote E, Garcia Ybarra PL. Flame propagation over liquid alcohols: Part I. Experimental results. J Therm Anal Calorim. 2005;80(3):541–8.

Degroote E, Garcia Ybarra PL. Flame propagation over liquid alcohols: Part III. Pulsating regime. J Therm Anal Calorim. 2005;80(3):555–8.

Degroote E, Garcia Ybarra PL. Flame propagation over liquid alcohols: Part II. Steady propagation regimes. J Therm Anal Calorim. 2005;80(3):549–53.

Gharagheizi F, Keshavarz MH, Sattari M. A simple accurate model for prediction of flash point temperature of pure compounds. J Therm Anal Calorim. 2011;110(2):1005–12.

GB 50160-2008. Fire prevention code of petrochemical enterprise design. Beijing: Ministry of Construction of China; 2008.

NFPA 30. Flammable and combustible liquids code. Quincy: National Fire Protection Association; 2011.

Biteau H, et al. Calculation methods for the heat release rate of materials of unknown composition. In: Proceedings of 9th IAFSS international symposium on fire safety science. 2008. https://doi.org/10.3801/iafss.fss.9-1165.

Mingyi C, et al. Investigation on the thermal hazards of 18650 lithium ion batteries by fire calorimeter. J Therm Anal Calorim. 2015;122(2):755–63.

ISO 5660-1:2015. Reaction-to-fire tests—heat release, smoke production and mass loss rate—Part 1: heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement). Geneva: International Organization for Standardization; 2015.

Wenxia Z, et al. Combustion calorimetry of carbonate electrolytes used in lithium ion batteries. J Fire Sci. 2015;33(1):22–36.

Junhyun K, Lee J-H, Kim S. Estimating the fire behavior of wood flooring using a cone calorimeter. J Therm Anal Calorim. 2011;110(2):677–83.

Chen R, Shouxiang L, et al. Correlation analysis of heat flux and cone calorimeter test data of commercial flame-retardant ethylene-propylene-diene monomer (EPDM) rubber. J Therm Anal Calorim. 2016;123(1):545–56.

Qiang X, Jin C, Jiang Y. Compare the flammability of two extruded polystyrene foams with micro-scale combustion calorimeter and cone calorimeter tests. J Therm Anal Calorim. 2017;127(3):2359–66.

Ran T, et al. Effects of low air pressure on radiation-controlled rectangular ethanol and n-heptane pool fires. Proc Combust Inst. 2013;34(2):2591–8.

Changfa T, et al. Effects of oblique air flow on burning rates of square ethanol pool fires. J Hazard Mater. 2013;260:552–62.

Chow WK. Comment on estimating heat release rate for a design fire in sprinkler protected area. Int J Eng Perform-Based Fire Codes. 2005;7(1):1–5.

NFPA 92B. Guide for smoke management systems in malls, atria, and large areas. Quincy: National Fire Protection Association; 2000. p. 2000.

Kim HJ, Lilley DG. Heat release rates of burning items in fires. J Propul Power. 2002;18(4):866–70.

McCaffrey BJ. Purely buoyant diffusion flames: some experimental results, NBSIR 79–1910. Maryland: National Bureau of Standards; 1979.

Hu J. Studies on the flame necking-in characteristic and temperature profile in developing area of pool fires. Master thesis. University of Science and Technology of China; 2015.

Liaw HJ, Chiu YY. The prediction of the flash point for binary aqueous-organic solutions. J Hazard Mater. 2003;101(2):83–106.

Le Cong T, Dagaut P. Experimental and detailed modeling study of the effect of water vapor on the kinetics of combustion of hydrogen and natural gas, Impact on NOx. Energ Fuel. 2009;23(2):725–34.

Dryer FL. Water addition to practical combustion systems—concepts and applications. Symp (Int) Combust. 1977;6(1):279–95. https://doi.org/10.1016/s0082-0784(77)80332-9.

Pandiana M, Sivapirakasamb SP, Udayakumarc M. Investigations on emission characteristics of the pongamia biodiesel–diesel blend fuelled twin cylinder compression ignition direct injection engine using exhaust gas recirculation methodology and dimethyl carbonate as additive. J Renew Sustain Ener. 2010;2(4):043110.

Bruno TJ, Wolk A, Naydich A, Huber ML. Composition-explicit distillation curves for mixtures of diesel fuel with dimethyl carbonate and diethyl carbonate. Energy Fuels. 2009;23(8):3989–97.

Li Dan, Fang Wenjun, et al. Effects of dimethyl or diethyl carbonate as an additive on volatility and flash point of an aviation fuel. J Hazard Mater. 2009;161:1193–201.

Acknowledgements

This research was supported by National Natural Science Foundation of China (No: 51376172 and No. 51706218). In addition, we deeply appreciate the support of Suqian City Public Security Fire Brigade in Jiangsu province of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Q., Wang, X., Zhou, T. et al. Investigation on the fire hazard characteristics of ethanol–water mixture and Chinese liquor by a cone calorimeter. J Therm Anal Calorim 135, 2297–2308 (2019). https://doi.org/10.1007/s10973-018-7323-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7323-7