Abstract

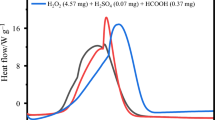

It is known that rubber mixes containing vegetable oils and vulcanized vegetable oils give better flow properties, plasticizing action, low temperature flexibility and ozone resistance. Now, in this investigation, the aim was to provide additional information about the effect of two vegetable oils (linseed oil and peanut oil) upon accelerated sulfur vulcanization system using thermal analysis—differential scanning calorimetry (DSC) and thermogravimetry. Several combinations of curatives (ZnO, sulfur and 2-t-butylbenzothiazole sulfenamide or TBBS) with stearic acid or vegetable oils were investigated, and DSC curves showed that vulcanization systems where linseed oil or peanut oil replaced stearic acid as activator proceeded an outline of basic steps similar to conventional mixture. However, the formation of the complex between Zn2+, sulfur and products of TBBS decomposition, main step in the vulcanization reaction, required much more energy. Exothermic ΔH values of 45.4 and 20.3 J g−1 were found for ZnO/S/TBBS/linseed oil and ZnO/S/TBBS/peanut oil, respectively, against only 5.8 J g−1 in the case of ZnO/S/TBBS/stearic acid mixture.

Similar content being viewed by others

References

Coran AY. Chemistry of the vulcanization and protection of elastomers: a review of the achievements. J Appl Polym Sci. 2003;87(1):24–30.

Joseph AM, George B, Madhusoodanan KN, Alex R. Current status of sulphur vulcanization and devulcanization chemistry: process of vulcanization. Rubber Sci. 2015;28(1):82–121.

Bateman L, Moore CG, Porter M, Saville B. In: Bateman L, editor. The chemistry and physics of Rubber-like substances. London: Maclaren and Sons Ltda; 1963.

Chapman AV, Porter M. Sulphur vulcanization chemistry. In: Roberts AD, editor. Natural rubber science and technology. London; 1988. p. 511.

Apreem AS, Joseph K, Thomas S. Recent developments in crosslinking of elastomers. Rubber Chem Technol. 2005;78(3):458–88.

Henning SK. Reduced zinc loading: using ZMMA to active accelerated sulphur vulcanization. Rubber World. 2008;238:35–42.

Suarez PAZ, Maneghetti SMP, Maneghetti MR, Wolf CR. Transformação de triglicerídeos em combustíveis, materiais poliméricos e insumos químicos: algumas aplicações da catálise na oleoquímica. Quim Nova. 2007;30(3):667–76.

Gamage PK, O’Brien M, Karunanayake L. Epoxidation of some vegetable oils and their hydrolysed products with peroxyformic acid—optimized to industrial scale. J Nat Sci Found Sri Lanka. 2009;37(4):229–40.

Dlugogorski BZ, Kennedy EM, Mackie JC. Low temperature oxidation of linseed oil: a review. Fire Sci Rev. 2012;1(3):1–36.

Datta J, Glowinska E. Chemical modifications of natural oils and examples of their usage for polyurethane synthesis. J Elastomers Plast. 2014;46(1):33–42.

Kuriakose AP, Varghese M. The compounding of nitrile and polychloroprene rubbers with rice bran oil. Iran Polym J. 1999;8(4):247–55.

Jayewardhana WGD, Perera GM, Edirisinghe DG, Karunanayake L. Study on natural oils as alternative processing aids and activators in carbon black filled natural rubber. J Nat Sci Found Sri Lanka. 2009;37(3):187–93.

Chandrasekara G, Mahanama MK, Edirisinghe DG, Karunanayake L. Epoxidized vegetable oils as processing aids and activators in carbono-black filled natural rubber compounds. J Nat Sci Found of Sri Lanka. 2011;39(3):243–50.

Ismail H, Salmiah I, Tsukahara Y. Palm oil fatty acid as an activator in carbon black filled natural rubber compounds: effect of vulcanization system. Polym Int. 1997;44(4):523–9.

Ismail H, Ruhaizat TA. Effect of palm oil fatty acid on curing characteristics and mechanical properties of CaCO3 filled natural rubber compounds. Iran Polym J. 1997;6(2):97–104.

Ismail H, Kamal SK, Mark SE. The comparison effects of palm oil fatty acid and stearic acid in various natural rubber compounds. J Elastomers Plast. 2001;33(2):100–13.

Bezerra A, Santos ACS, da Costa HM, Ramos VD. Efeito do óleo de linhaça e do óleo de amendoim sobre a vulcanização da borracha natural (NR). Parte I: modelo generalizado. Polímeros. 2013;23(3):395–401.

Bezerra A, Santos ACS, da Costa HM, Ramos VD. Efeito do óleo de linhaça e do óleo de amendoim sobre a vulcanização da borracha natural (NR). Parte II: modelo detalhado. Polímeros. 2013;23(4):493–500.

Aboissa óleos vegetais. 2015. http://www.aboissa.com.br/produtos. Accessed 20 Jan 2015.

Ganjali ST, Malekzadeh M, Farahani M, Abbasian A, Khosravi M. Effect of surface-modified zinc oxide as cure activator on the properties of a rubber compound based on NR/SBR. J Appl Polym Sci. 2011;122(1):249–56.

Kok CM. A thermal analysis study of the interactions of curatives in the accelerated sulphur vulcanization system. Eur Polym J. 1985;21(6):579–82.

Gradwell MHS, McGill WJ. The thermal decomposition of sulfenamide accelerators. J Appl Polym Sci. 1994;51(1):169–76.

Gradwell MHS, McGill WJ. Sulfur vulcanization of polyisoprene accelerated by benzothiazole derivatives. IV. The reaction of polyisoprene with N-cyclohexylbenzothiazole sulfenamide, sulfur, and zinc oxide. J Appl Polym Sci. 1996;61(9):1515–23.

Morrison NJ. The formation of crosslink precursors in the sulfur vulcanization of natural rubber. Rubber Chem Technol. 1984;57(1):97–103.

Ding R, Leonov AI. A kinetic model for sulfur accelerated vulcanization of a natural rubber compound. J Appl Polym Sci. 1996;61(3):455–63.

Solomons TWG. Alkenes and alkynes I. Properties and synthesis. In: Fundamentals of organic chemistry. 3rd ed. New York: Wiley; 1990. (chapter 6).

Moser BR. Comparative oxidative stability of fatty acid alkyl esters by accelerated methods. J Am Oil Chem Soc. 2009;86(7):699–706.

Acknowledgements

The authors gratefully acknowledge the research grant provided by Programa Bolsista Produtividade da UNESA/2016 and thank FAPERJ, CAPES and CNPq for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

da Costa, H.M., Ramos, V.D., da Costa Campbell, B. et al. Thermal analysis of the sulfur vulcanization. J Therm Anal Calorim 129, 755–766 (2017). https://doi.org/10.1007/s10973-017-6199-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6199-2