Abstract

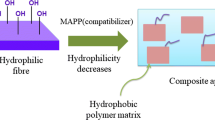

In this work, carbon fiber (CF)-reinforced polypropylene (PP) composites were prepared by melt processing with maleic anhydride-grafted polypropylene as compatibilizer. The mechanical properties and crystallization behaviors of the resulting composites were investigated detailedly. The interfacial compatibility of CRP composites was fine and CF dispersed in PP matrix homogeneously. CF played a nucleation agent for the crystallization of PP. The crystallization temperature increased with increasing CF content. Carbon fibers could act as the heterogeneous nucleation agent for PP, which would decrease the activation energy of crystallization, shorten the crystallization time and raise the crystallization rate dramatically. The original spherulite morphology of neat PP was also destroyed by CF. CF exhibited obvious reinforcing effects on PP matrix and improved the mechanical properties of PP materials. The tensile strength and flexural strength were increased over 100% with 20 mass% CF.

Similar content being viewed by others

References

Feng J, Zhou H, Wang X, Mi J. Theory of crystals and interfaces in polyethylene and isotactic polypropylene. J Phys Chem C. 2016;120:8630–9.

Kersch M, Schmidt H-W, Altstädt V. Influence of different beta-nucleating agents on the morphology of isotactic polypropylene and their toughening effectiveness. Polymer. 2016;98:320–6.

Wang K, Bahlouli N, Addiego F, Ahzi S. Elastic and yield behaviors of recycled polypropylene-based composites: experimental and modeling study. Compos Part B Eng. 2016;99:132–53.

Lin Z, Cao L, Guan Z, Lin H, Chongming D, Wang Y, Gaosun W, Li W. Grafting polypropylene and treatment of calcium carbonate to improve structure and properties of polypropylene composites. J Therm Anal Calorim. 2014;117:65–772.

Chen S, Wang X, Ma X, Wang K. Morphology and properties of polypropylene/nano-CaCO3 composites prepared by supercritical carbon dioxide-assisted extrusion. J Mater Sci. 2016;51:708–18.

Majka TM, Bartyzel O, Raftopoulos KN, Pagacz J, Leszczyńska A, Pielichowski K. Recycling of polypropylene/montmorillonite nanocomposites by pyrolysis. J Anal Appl Pyrol. 2016;119:1–7.

Pedrazzoli D, Pegoretti A, Kalaitzidou K. Interfacial interactions in silica-reinforced polypropylene nanocomposites and their impact on the mechanical properties. Polym Compos. 2016;37:2018–26.

Fukuyama Y, Senda M, Kawai T, Kuroda S, Toyonaga M, Taniike T, Terano M. The effect of the addition of polypropylene-grafted SiO2 nanoparticle on the thermal conductivity of isotactic polypropylene. J Therm Anal Calorim. 2014;117:1397–405.

Dou Q, Duan J. Melting and crystallization behaviors, morphology, and mechanical properties of β-polypropylene/polypropylene-graft-maleic anhydride/calcium sulfate whisker composites. Polym Compos. 2016;37:2121–32.

Cabrera A, Sharma P, Ayala M, Rubio-Perez L, Amézquita-Valencia M. Fabrication of exfoliated graphene-based polypropylene nanocomposites with enhanced mechanical and thermal properties. Polymer. 2011;52:4001–10.

Hu D, Chen J, Zhao L, Liu T. Melting and non-isothermal crystallization behaviors of polypropylene and polypropylene/montmorillonite nanocomposites under pressurized carbon dioxide. Thermochim Acta. 2015;617:65–75.

Abadchi MR, Jalali-Arani A. Crystallization and melting behavior of polypropylene (PP) in (vulcanized nanoscale polybutadiene rubber powder/PP) polymer-nanocomposites. Thermochim Acta. 2015;617:120–8.

Ameli A, Jung PU, Park CB. Electrical properties and electromagnetic interference shielding effectiveness of polypropylene/carbon fiber composite foams. Carbon. 2013;60:379–91.

Xu S, Akchurin A, Liu T, Wood W, Tangpong XW, Akhatov I, Zhong W. Thermal properties of carbon nanofiber reinforced High-Density polyethylene nanocomposites. J Compos Mater. 2015;49:795–805.

Li J. The research on the interfacial compatibility of polypropylene composite filled with surface treated carbon fiber. Appl Surf Sci. 2009;255:8682–4.

Savasa LA, Tayfun U, Dogan M. The use of polyethylene copolymers as compatibilizers in carbon fiber reinforced high density polyethylene composites. Compos Part B Eng. 2016;99:188–95.

Shen L, Wang FQ, Yang H, Meng QR. The combined effects of carbon black and carbon fiber on the electrical properties of composites based on polyethylene or polyethylene/polypropylene blend. Polym Test. 2011;30:442–8.

Molazemhosseini A, Tourani H, Naimi-Jamal MR. Nanoindentation and nanoscratching responses of PEEK based hybrid composites reinforced with short carbon fibers and nano-silica. Polym Test. 2013;32:525–34.

Rezaei F, Yunus R. Development of short-carbon-fiber-reinforced polypropylene composite for car bonnet. Polym Plast Technol Eng. 2008;47:351–7.

Xu Z, Chen L, Huang Y, Li J, Wu X, Li X, Jiao Y. Wettability of carbon fibers modified by acrylic acid and interface properties of carbon fiber/epoxy. Eur Polym J. 2008;44:494–503.

Fu SY, Lauke B, Mäder E, Yue CY, Hu X. Tensile properties of short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Compos Part A Appl Sci Manuf. 2000;31:1117–25.

Rezaei F, Yunus R, Ibrahim NA. Effect of fiber length on thermomechanical properties of short carbon fiber reinforced polypropylene composites. Mater Des. 2009;30:260–3.

Xiang G, Huafeng T, Qian L, Yan L, Aimin X. Effect of compatilizer on rheological and mechanical properties of polypropylene/carbon fiber composite. Plast. 2016;45:4–6.

Sperling LH. Introduction to physical polymer science. New York: Wiley; 2005.

Shi J, Yang X, Wang X, Lu L. Non-isothermal crystallization kinetics of nylon 6/attapulgite nanocomposites. Polym Test. 2010;29:596–602.

Lin F, Tian H, Jia Q, Xiang A, Li Y, Pan W, Xu H. Non-isothermal crystallization behaviors of polyvinyl alcohol/hydroxyethyl cellulose blend films. J Polym Environ. 2013;21:343–9.

Lorenzo AT, Arnal ML, Albuerne J, Müller AJ. DSC isothermal polymer crystallization kinetics measurements and the use of the Avrami equation to fit the data: guidelines to avoid common problems. Polym Test. 2007;26:222–31.

Fu SY, Lauke B, Mader E, Hu X, Yue CY. Tensile properties of short-glass-fiber and short-carbon-fiber-reinforced polypropylene composites. Compos Part A: Appl Sci Manuf. 2000;31:1117–25.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51373004), Innovation Ability Promotion Plan of Beijing Municipal Commission of Education (PXM2013_014213_000097), Beijing Top Young Innovative Talents Program (2014000026833ZK13) and Open Funding of State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, Donghua University (LK1406).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, H., Zhang, S., Ge, X. et al. Crystallization behaviors and mechanical properties of carbon fiber-reinforced polypropylene composites. J Therm Anal Calorim 128, 1495–1504 (2017). https://doi.org/10.1007/s10973-016-5996-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5996-3