Abstract

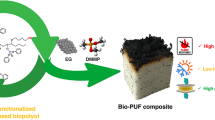

Liquefied lignin-based polyol (LBP) was successfully obtained by liquefying calcium lignosulphonate with a polyhydroxy alcohol mixture, which can substitute 30 % petroleum-based polyether polyol to prepare rigid polyurethane foam (RPUF). In an effort to reduce the flammability and smoke release from RPUF, liquefied LBP in combination with commercial flame retardant polyol (FRP), polyurethane microencapsulated ammonium polyphosphate (MAPP) and organically modified layered double hydroxide (OLDH) were used to fabricate halogen-free flame retardant RPUF nanocomposite. The influences of incorporating LBP, FRP, MAPP and OLDH into RPUF on the thermal conductivity, mechanical property, thermal performance, flame retardancy and fire behaviors of RPUFs were comprehensively investigated. It is noteworthy that simultaneously incorporating LBP, FRP, MAPP and OLDH into RPUF can significantly improve the mechanical property, thermal performance, flame retardancy and fire behavior of RPUF. The improved flame retardancy and fire behavior of RPUF are attributable to combined effects among LBP, FRP, MAPP and OLDH in gas phase and condensed phase.

Similar content being viewed by others

References

Levchik SV, Weil ED. Thermal decomposition, combustion and fire-retardancy of polyurethanes-a review of the recent literature. Polym Int. 2004;53:1585–610.

Chiellini E, Cinelli P, Chiellini F, Imam SH. Environmentally degradable bio-based polymeric blends and composites. Macromol Biosci. 2004;4:218–31.

Petrović ZS. Polyurethanes from vegetable oils. Polym Rev. 2008;48:109–55.

Ionescu M, Wan X, Bilić N, Petrovic ZS. Polyols and rigid polyurethane foams from cashew nut shell liquid. J Polym Environ. 2012;20:647–58.

Lora JH, Glasser WG. Recent industrial applications of lignin: a sustainable alternative to nonrenewable materials. J Polym Environ. 2002;10:39–48.

Stewart D. Lignin as a base material for materials applications: chemistry, application and economics. Ind Crops Prod. 2008;27:202–7.

Hatakeyama H. Lignin structure, properties, and applications. Adv Polym Sci. 2010;232:1–63.

Pan H. Synthesis of polymers from organic solvent liquefied biomass: a review. Renew Sustain Energy Rev. 2011;15:3454–63.

Evtuguin DV, Andreolety JP, Gandini A. Polyurethanes based on oxygen organosolv lignin. Eur Polym J. 1998;34:1163–9.

Cateto CA, Barreiro MF, Rodrigues AE. Monitoring of lignin based polyurethanes synthesis by FTIR-ATR. Ind Crops Prod. 2008;27:168–74.

Hatakeyama H, Hirogaki A, Matsumura H, Hatakeyama T. Glass transition temperature of polyurethane foams derived from lignin by controlled reaction rate. J Therm Anal Calorim. 2013;114:1075–82.

Wu LCF, Glasser WG. Polyurethane adhesives and coatings from modified lignin. J Appl Polym Sci. 1984;9:1111.

Hatakeyama H, Kosugi R, Hatakeyama T. Thermal properties of lignin- and molasses-based polyurethane foams. J Therm Anal Calorim. 2008;92:419–24.

Nadji H, Bruzzese C, Belgacem MN, Benaboura A, Gandini A. Oxypropylation of lignins and preparation of rigid polyurethane foams from the ensuing polyols. Macromol Mater Eng. 2005;209:1009–16.

Cateto CA, Barreiro MF, Rodrigues AE, Belgacem MN. Optimization study of lignin oxypropylation in view of the preparation of polyurethane rigid foams. Ind Eng Chem Res. 2009;48:2583–9.

Gao LP, Zheng GY, Zhou YH, Hu LH, Feng GD. Thermal performances and fire behaviors of rosin-based rigid polyurethane foam nanocomposites. J Therm Anal Calorim. 2015;119:411–24. doi:10.1007/s10973-014-4192-6.

Jasiukaityté E, Kunaver M, Crestini C. Lignin behaviour during wood liquefaction-characterization by quantitative 31P, 13C NMR and size-exclusion chromatography. Catal Today. 2010;156:23–30.

D’Souza J, Yan N. Producing bark-based polyols through liquefaction: effect of liquefaction temperature. ACS Sustain Chem Eng. 2013;1:534–40.

Hatakeyama T, Quinn FX. Thermal analysis, fundamentals and applications to polymer science. 2nd ed. Chichester: Wiley; 1999.

Zhang H, Pang H, Ji H, Fu T, Liao B. Investigation of liquefied wood residues based on cellulose, hemicellulose and lignin. J Appl Polym Sci. 2012;123:850–6.

Thirumal M, Khastgir D, Nando GB, Naik YP, Singh NK. Halogen-free flame retardant PUF: effect of melamine compounds on mechanical, thermal and flame retardant properties. Polym Degrad Stab. 2010;95:1138–45.

Gao LP, Zheng GY, Zhou YH, Hu LH, Feng GD, Zhang M. Synergistic effect of expandable graphite, diethyl ethylphosphonate and organically-modified layered double hydroxide on flame retardancy and fire behavior of polyisocyanurate–polyurethane foam nanocomposite. Polym Degrad Stab. 2014;101:92–101.

Thirumal M, Khastgir D, Singha NK, Manjunath BS, Naik YP. Mechanical, morphological and thermal properties of rigid polyurethane foam: effect of the fillers. Cell Polym. 2007;26:245–59.

Lu SY, Hamerton I. Recent developments in the chemistry of halogen-free flame retardant polymers. Prog Polym Sci. 2002;27:1661–712.

Hatakeyamaa T, Matsumoto Y, Asano Y, Hatakeyama H. Glass transition of rigid polyurethane foams derived from sodium lignosulfonate mixed with diethylene, triethylene and polyethylene glycols. Thermochim Acta. 2004;416:29–33.

Matusinovic Z, Wilkie CA. Fire retardancy and morphology of layered double hydroxide nanocomposites: a review. J Mater Chem. 2012;22:18701–4.

Kashiwagi T, Du FM, Douglas JF, Winey KI, Harris RH, Shields JR. Nanoparticle networks reduce the flammability of polymer nanocomposites. Nat Mater. 2005;4:928–33.

Modestia M, Lorenzettia A, Simionia F, Checchinb M. Influence of various flame retardants on fire behavior of modified PIR/PUR polymers. Polym Degrad Stab. 2001;74:475–9.

Blomfeldt TOJ, Nilsson F, Holgate T, Xu JX, Johansson E, Hedenqvist MS. Thermal conductivity and combustion properties of wheat gluten foams. ACS Appl Mater Interfaces. 2012;4:1629–35.

Acknowledgements

This work was financially supported by the Jiangsu Province Natural Science Foundation of China (Grant No. BK20130071) and the National 12th Five-year Science and Technology Support Plan (Grant No. 2012BAD32B05).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, L., Zheng, G., Zhou, Y. et al. Improved mechanical property, thermal performance, flame retardancy and fire behavior of lignin-based rigid polyurethane foam nanocomposite. J Therm Anal Calorim 120, 1311–1325 (2015). https://doi.org/10.1007/s10973-015-4434-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4434-2