Abstract

We have developed a new method to measure the thermal conductivity of powders by differential scanning calorimetry that works with masses in amounts as low as tens of mg. The method is based on that used by Camirand to determine the thermal conductivity of materials in the form of thin sheets but introducing a hemispherical pan to contain powders in such a way that the issue of heat transfer is reduced to a one-dimensional problem. The modification of the method was successfully validated on obtaining identical results in determining the thermal conductivity of a commercial silicone with both Camirand’s method and the modified method. We have also tested our method with materials that, in bulk, cover a wide range of thermal conductivities and have performed the experiments with several atmospheres and reference metals. The results are consistent with already published general trends in that they confirm that thermal conductivity of powders is mainly governed by thermal conduction through the surrounding gas.

Similar content being viewed by others

References

Novichenok LN, Ovchinniko SM, Marshak VA. Thermal conductivity probe e.g. for complex liquids and powders—has cylinder wound alternately with heater and resistance thermometer turns. 1986; Patent n.SU1264053-A.

Roura P, Sanchez-Rodriguez D, Farjas J. Measurement by differential scanning calorimetry of specific heat capacity variation due to crystallization: application to amorphous silicon. Thermochim Acta. 2011;522:161–5.

Marcus SM, Blaine RL. Thermal-conductivity of polymers, glasses and ceramics by modulated DSC. J Therm Anal Calorim. 1994;243:231–9.

Kalogiannakis G, Van Hemelrijck D, van Assche G. Measurements of thermal properties of carbon/epoxy and glass/epoxy using modulated temperature differential scanning calorimetry. J Compos Mater. 2004;38:163–75.

Camirand CP. Measurement of thermal conductivity by differential scanning calorimetry. Thermochim Acta. 2004;417:1–4.

Flynn JH, Levin DM. A method for the determination of thermal conductivity of sheet materials by differential scanning calorimetry. Thermochim Acta. 1988;126:93–100.

Tavman I, Aydogdu Y, Kök M, Turgut A, Ezan A. Measurement of heat capacity and thermal conductivity of HDPE/expanded graphite nanocomposites by differential scanning calorimetry. Arch Mater Sci Eng. 2011;50:56–60.

Hakvoort G, Vanreijen LL, Aartsen AJ. Measurement of the thermal conductivity of solid substances by DSC. Thermochim Acta. 1985;93:317–20.

Klemensiewicz Z. Thermal conductivity of powders. Nature. 1949;164:589.

Huang L, El-Genk MS. Thermal conductivity measurements of alumina powders and molded Min-K in vacuum. Energy Convers Manag. 2001;42:599–612.

Ming Y, Purewal J, Liu D, Sudik A, Xu Ch, Yang J, Veenstra M, Rhodes K, Soltis R, Warner J, Gaab M, Müller U, Siegel DJ. Thermophysical properties of MOF-5 powders. Microporous Mesoporous Mater. 2014;185:235–244.

Huang BL, Ni Z, Millward A, McGaughey AJH, Uher C, Kaviany M, Yaghi O. Thermal conductivity of a metal-organic framework (MOF-5): part II. Measurement. Int J Heat Mass Transf. 2007;50:405–11.

Mullokandov RL. J Tech Phys. U.S.S.R., 1947; 17:1149 (Phys. Abstr., 1432 (1947)).

Acknowledgements

This work was partially funded by the Spanish Programa Nacional de Materiales through projects MAT2011-28874-C02-02 and by the Generalitat de Catalunya contract No. 2009SGR-185. The authors wish to thank the University of Girona for the PhD fellowship granted to Daniel Sánchez-Rodríguez and for the use of the thermal analysis facilities (ServeisTècnics de Recerca).

Author information

Authors and Affiliations

Corresponding author

Appendix: Slope of the DSC signal during melting

Appendix: Slope of the DSC signal during melting

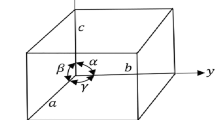

During melting, the metal reference remains at the melting temperature, T M, whereas the DSC furnace is heated at a constant heating rate, β. Let us first demonstrate that any point r of the powder contained in the hemispherical holder (Fig. 1) will experience a constant heating rate according to the formula:

where t is time, f is a time-independent function and R is the thermal resistance of the powder inside the radius r, i.e.:

where κ is the powder thermal conductivity. Notice that the heating rate of the powder varies from zero at r i to its maximum value β e at r e.

We must simply verify that T(r,t) of Eq. (4) satisfies the heat transport equation that, given the spherical symmetry of the system, can be written as:

or, substituting r by R in the partial derivatives:

where ρ and c are the density and specific heat of the powder, respectively. This verification is straightforward after the introduction of Eq. (4) into (7), and is left for the reader.

Once demonstrated that the powder in contact with the pan (at r = r e ) is heated at a constant rate, the value of β e will be calculated with the assumption that we can neglect both the pan resistance and its contact resistance with the DSC sensor (i.e. T S = T e—see Fig. 1). We must simply impose a power measured by the DSC, \( \dot{Q}_{{_{\text{DSC}} }} \) equal to the heat that enters into the powder through the pan’s inner surface, \( \dot{Q}_{\text{e}} \). \( \dot{Q}_{{_{\text{DSC}} }} \) can be easily calculated through the formula:

where R is the thermal resistance of the DSC sensor, T REF is the reference temperature that changes at the programmed heating rate:

and T e is given by Eq. (4) at r = r e. We obtain:

where A is time-independent. On the other hand, \( \dot{Q}_{\text{e}} \) is proportional to the temperature gradient at r e :

Introduction of Eqs. (4) and (5) into Eq. (11) gives:

where B is time-independent. Now, the condition \( \dot{Q}_{\text{DSC}} = \dot{Q}_{\text{e}} \) delivers the value of β e:

And, finally, the slope of the DSC signal can be obtained after the substitution of β e in Eq. (10):

If the contact resistance between the pan and the DSC sensor were not negligible, the result would be 1/R + R c + R e.

Rights and permissions

About this article

Cite this article

Sánchez-Rodríguez, D., López-Olmedo, J.P., Farjas, J. et al. Determination of thermal conductivity of powders in different atmospheres by differential scanning calorimetry. J Therm Anal Calorim 121, 469–473 (2015). https://doi.org/10.1007/s10973-015-4429-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4429-z