Abstract

In the study, the effect of lactose–maltodextrin and trehalose–maltodextrin matrices on the glass transition temperatures and moisture sorption characteristics of spray-dried β-lactoglobulin–vitamin D3 complexes was investigated. Incorporation of sugars into complexes can influence the thermal properties and moisture sorption characteristics of powders. The glass transition temperature as an important physiochemical parameter that determines the processing conditions, product quality and stability of the final product was studied with the use of modulated differential scanning calorimetry method. Moisture sorption isotherms, water activity and moisture content as parameters related to sorption properties, were also investigated. Additionally, particle size, wettability and insolubility index were studied to characterise newly synthesized products. For the samples tested, two well-separated glass transitions were found. The dominant effect of maltodextrin on the glass transition temperatures was observed. An increase in the percentage of maltodextrin added resulted in increasing T g value of studied complexes. At low water activity all powdered complexes showed typical sorption behaviour of food systems. Trehalose as a carbohydrate component of powdered complexes, in comparison to lactose, delayed the occurrence of crystallization.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The glass transition temperature and moisture sorption behaviour are important physiochemical parameters that largely determine the processing conditions, product quality (such as stickiness, hygroscopicity and caking behaviour) and stability (storability and handling) of the final product [1]. The glass transition temperature (T g) is the temperature at which polymeric materials change from an amorphous solid (glass) to an amorphous rubber and is assumed to control the rate of physical changes in food [2]. The glass transition temperature affects the texture of foods as well as storage stability of dried foods [3]. Food products are expected to be fairly stable below the T g but when the temperature rises above T g, a solid structure is transformed to a supercooled liquid state with time-dependent flow [3–5]. The glass transition behaviour of carbohydrates (lactose, trehalose, maltodextrin) is well-known, but higher T g may be obtained for carbohydrate–protein systems than for carbohydrates alone. The higher T g of carbohydrate–protein mixtures may increase the stability of food products [6]. In drying of food products, glass transition temperature is one of the important factors that needs to be considered seriously [7]. The technique that gives the possibility to analyse many aspects of the thermal response of materials, including particularly the glass transition is modulated differential scanning calorimetry (ang. MDSC) [8]. It involves the application of a sinusoidal heating or cooling signal to a sample and the subsequent measurement of the reversing and non-reversing components of the heat flow response [9–11].

Food powders are often prone to sticking and caking problems. Since water is responsible for such problems, moisture sorption isotherms are a useful tool for understanding the moisture relationship of powders and consequently their stability problems. The relationship between water content and water activity (a w) is complex. An increase in a w is almost always accompanied by an increase in the water content, but in a nonlinear trend. Moisture sorption isotherms describe the equilibrium relationship between the moisture content of the powder and the relative humidity of the surrounding environment [12, 13]. There are many water sorption models in food science. Those having strong theoretical basis and position in food science are proposed by: Halsey, Lewicki, Henderson, Chung and Pfost, Ferro Fontan et al. and Guggenheim, Anderson and De Boer (GAB) [14]. The knowledge of T g profiles together with isotherms can provide important information about the stability of newly synthesized β-lactoglobulin (β-LG)–cholecalciferol complexes with lactose–maltodextrin and trehalose–maltodextrin addition, obtained in form of spray-dried powders. β-LG was employed to create complexes with cholecalciferol due to its amino-acid sequence and 3-D structure, which make it capable of binding a variety of fat-soluble ligands [15–18]. The binding properties of β-LG make it a potential ingredient to deliver vitamin D3 in a form of spray-dried complex with β-LG to fat free food systems. Spray drying belongs to one of the mostly used drying methods in the food industry due to the wide availability of the equipment, a large variety of carriers and good final product stability [19, 20]. Spray-dried powders are economical compared to other processes such as freeze-drying with advantages of fascinating manipulation, transport, storage and consumption. During the drying process, proteins can unfold due to dehydration stress [21], although the droplets reach only the relatively low wet bulb temperature by high rates of moisture evaporated [22]. It can result in dissociation of the complex and low retention of vitamin D3. Certain sugars, such as lactose, trehalose were found to limit the conformational changes and stabilize whey protein during spray drying [23, 24]. The saccharides are able to form a glassy state of a very high viscosity and low mobility and restrict the mobility of protein as well as its unfolding [25]. Additives such as lactose, trehalose remain in the amorphous phase with the protein and bind to the protein in the place of water during drying which prevents the stability problems. Large polymers, such as maltodextrin do not inhibit protein unfolding during drying because steric hindrance prevents effective hydrogen bonding to proteins [26]. Incorporation of polymers to complexes could be beneficial because of their relatively high T g values. Maltodextrin–lactose and maltodextrin–trehalose mixtures used in spray drying are thought to improve the process and provide optimal protection to proteins during drying. Such molecular matrices forming glassy state have received relatively little attention.

The aim of the present study was to determine the effect of lactose–maltodextrin and trehalose–maltodextrin systems on the glass transition temperatures and sorption characteristics of β-LG–vitamin D3 complexes. Water activity and moisture content as parameters related to sorption properties were also studied. Additionally, particle size, wettability and insolubility index were investigated to characterise newly synthesized products.

Materials and methods

Materials

BioPURE β-LG containing 95 % β-LG was provided as powder by Davisco Foods International, Inc. (Le Sueur, Minnesota). Cholecalciferol (vitamin D3) and α-lactose monohydrate were purchased from Sigma Chemical Co. (St. Louis, Missouri) and were of the highest analytical quality. Trehalose and maltodextrin with the dextrose equivalent (D.E.) 15 were purchased from Hortimex Ltd Co. (Konin, Poland).

Methods

Solution preparation

400 ml of β-LG (M = 18 400 g mol−1) solution was prepared by gently adding distilled water into 8.6 g (0.47 mmol) of the protein while stirring slowly to avoid heavy foaming. The mixture was kept at room temperature until a homogenous clear solution was formed. Then 0.36 g (0.94 mmol) of cholecalciferol (vitamin D3) (M = 384 g mol−1) dissolved in 800 μL absolute ethanol was added into the solution to obtain 2:1 molar ratio of vitamin D3 to protein. The solution was incubated at 40 °C for 2 h according to the method described by Kontopidis et al. [17]. Then the mixtures of maltodextrin (D.E. 15) with lactose or trehalose were added to the β-LG–vitamin D3 complexes. Maltodextrin were mixed with lactose or trehalose at different ratios for products D1–D6 as presented in Table 1.

Powder production

The β-LG–vitamin D3–carbohydrates complexes were spray-dried in a laboratory spray-dryer (Anhydro, Denmark) by a peristaltic pump, and atomised to small droplets by a centrifugal vaned atomizer wheel with a rotational speed of 39,000 rpm. The operational conditions of the spray drying were: air inlet temperature: 120 °C and flow rate: 51.4 mL min−1. The powders were collected at the bottom of the dryer’s cyclone. The products were kept in vacuum desiccators over CaCl2 at room temperature, in a dry place and in the absence of light. Powders were further dried in a vacuum oven at 50 °C for 24 h before experiments were carried out to remove residual moisture. The processes and analyses were carried out in triplicate.

MDSC studies

Modulated DSC experiments were performed on a TA Instrument Q200 differential scanning calorimeter (New Castle, USA). MDSC was used to determine the glass transition temperature of β-LG–vitamin D3 complexes with lactose–maltodextrin or trehalose–maltodextrin addition at water activity about 0. The cell was purged with 50 mL min−1 dry nitrogen and calibrated for baseline on an empty oven and for temperature using standard pure indium. Specific heat capacity (C p) was calibrated using a sapphire. An empty sealed aluminium pan was used as a reference in each test.

Complexes powders (10–13 mg) were non-hermetically sealed in aluminium pans (volume 30 μL) and cooled from room temperature to 10 °C at heating rate 5 °C per min and equilibrated for 5 min. In the case of MDSC, samples were scanned from 10 to 170 °C at a constant heating rate of 2 °C per min with an amplitude of ±1 °C and 60 s period of modulation. Curves were analysed with respect to the total, reversible and non-reversible heat flow [5, 27]. Glass transition was reported with parameters indicating its onset, midpoint and endpoint of a vertical shift in the reversing transition curve. TA Instruments Universal analysis software was used to analyse the glass transition temperature. The measurements were done in three replicates for each sample.

The change in heat capacity, ΔC p, was determined by taking the heat capacity difference between the solid and liquid baselines at the T g. The quasi-isothermal runs were done in the modulated mode using an amplitude of ±0.30 °C, a period of 120 s, and stepped incrementally every 3 °C. Measurements were conducted in 5 min intervals. Each measurement lasted 5 min.

Water content

Water content was measured by mass loss (0.5 g of a sample) after drying at 105 °C for 4 h [28].

Water activity

Water activity was measured using a Rotronic HygroLab C1 (Rotronic AG, Germany) at temperature 22 ± 1 °C.

Particle size

The mean particle size was determined with the solid particle size analyser in air AWK-V97 (Kamika, Warsaw, Poland), which uses a particle size measuring method based on measurement of changes in infrared radiation beam dispersed by particles moving within the measurement zone [29].

Wettability

Wettability of powders was determined according to Jinapong et al. [30]. 100 mL of distilled water (at 22 ± 1 °C) was poured into a beaker. A powder sample (0.1 g) was placed around the pestle (inside the funnel so that it blocked the lower opening) and lifted the pestle and started the stop. Finally, time was recorded when the powder became completely wetted (visually assessed when all the powder particles penetrated the surface of the water).

Insolubility index

Insolubility index was measured for the ability of a powder to dissolve in water. It is defined as the volume of sediments in milliliter after centrifuging [31].

Sorption isotherms

Water vapour sorption isotherms were determined using the static-gravimetric method. The products were stored at a stable relative humidity, which ranged from 0.0 to 0.92, for 3 months [32]. The products to be analysed were placed in desiccators and were kept at a constant temperature of 25 °C. Saturated salt solutions were prepared as hygroscopic factors. The salts used were: CaCl2, LiCl, CH3COOK, MgCl2, K2CO3, Mg(NO3)2, NaNO2, NaCl, (NH4)2SO4 and NH4H2PO4 with corresponding water activities of 0, 0.11, 0.23, 0.33, 0.44, 0.53, 0.65, 0.75, 0.81 and 0.92, respectively [29]. Sample weight was measured at time intervals during storage.

Sorption kinetics

The measurement of water vapour sorption kinetics was conducted using a stand which ensured continuous measurement of mass increase in the conditions of constant temperature and relative humidity [29]. Adsorption kinetics was determined at a temperature of 25 °C within 24 h at three levels of relative humidity of the environment (0.33, 0.65 and 0.92) obtained using saturated MgCl2, NaNO2 and NH4H2PO4 solutions. The investigated samples mass increase was registered using the Measurement for DOS software.

Statistical analysis

Each measurement was triplicate. The data were reported as the mean ± SD. Two-way ANOVA was conduced using Statgraphics Plus for Windows programme, version 4.1 (Statistical Graphics Corporation, Warrenton, VA, USA). Differences were considered to be significant at a P value of 0.05, according to Tukey’s Multiple Range Test.

Results and discussion

In the present study, the capability of β-LG to bind hydrophobic ligands was used to obtain β-LG–vitamin D3 complexes. In order to synthesize such complexes in spray-dried powders with high vitamin yield, it is important to protect β-LG from denaturation and the complex from dissociation during the drying process. In order to provide optimal protection to β-LG during drying, to decrease stickiness and improve shelf life of the final products, trehalose and lactose were combined with maltodextrin. Additives chosen for the study help to maintain protein structure during drying via hydrogen bonding and form an amorphous phase [33]. Incorporation of maltodextrin to complexes could be beneficial because of its relatively high T g values. Thus, β-LG–vitamin D3–lactose/maltodextrin and β-LG–vitamin D3–trehalose/maltodextrin complexes were synthesized in a form of spray-dried powders.

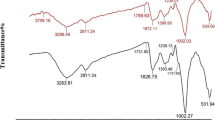

The glass transition temperature has been proven to be an effective indicator for food quality changes during storage. In the present study, DSC curves of reversing heat flow versus temperature were recorded to determine glass transitions’ temperatures of products. For clarity, two model DSC curves are presented in Fig. 1—first-recorded for β-LG–vitamin D3 complex containing lactose/maltodextrin system (D1) and second-recorded for β-LG–vitamin D3 complex containing trehalose/maltodextrin system (D5). Experimental values of the glass transition temperatures and specific heat change through the glass transition zone for the tested samples are presented in Tables 2 and 3, respectively. For the samples tested, it was possible to find two glass transitions well separated (Fig. 1). This is in agreement with the results obtained by Sacha and Nail [34]. They studied a series of sugars, including sucrose, lactose, trehalose, maltose, fructose, galactose, fucose, mannose and glucose, and observed double transitions for all sugars examined. The glass transitions presented in Table 2 are reported with parameters indicating their onset, midpoint and endpoint, so the width of the transitions is clear. In the case of first glass transition, the onset T g ranged from 42.59 ± 0.289 to 54.82 ± 0.566, the midpoint T g from 46.38 ± 0.331 to 58.13 ± 0.349 and the endpoint T g from 50.12 ± 0.179 to 61.43 ± 0.425. The obtained results show that glass transition temperatures vary depending on the composition of studied complexes. The dominant effect of maltodextrin on the glass transition temperatures was observed. An increase in the percentage of maltodextrin added resulted in increasing T g value of studied complexes. Complexes containing mixtures of lactose–maltodextrin and trehalose–maltodextrin in the ratio 70:30 (D-3 and D-6) showed the highest T g. The similar relationship can be seen in the case of second glass transition. The second glass transition temperatures (T g2 onset, T g2 midpoint, T g2 endpoint) are found to be about 5–11 above these, obtained for β-LG–vitamin D3–lactose complexes, without maltodextrin addition [35]. The dependance of glass transition temperature on the average molecular mass of the system has been previously mentioned [36]. The addition of polymers, such as maltodextrins results in increasing the T g of the product and consequently its stability [37]. It is worth mentioning that in applied conditions no glass transition was detected at a w = 0 in the case of β-LG–vitamin D3 complexes, without carbohydrates addition [35]. In food systems a higher T g can be assumed to improve protection and stability of encapsulated compounds. The glass transition temperatures of synthesized complexes were measured for powders conditioned at a w = 0. Therefore, in the future, the glass transition temperature should be obtained for a wide range of water activities.

Quasi-isothermal operation mode was used to reach the highest precision for the measurement of heat capacity. The heat capacity changes of β-LG–vitamin D3–lactose–maltodextrin complexes during first glass transition (ΔC p1) ranged from 0.048 J g−1 °C−1 ± 0.005 in the case of D2 powder to 0.323 J g−1 °C−1 ± 0.023 in the case of D1. For β-LG–vitamin D3–trehalose–maltodextrin complexes, the heat capacity changes ranged from 0.014 ± 0.004 for D-5 to 1.067 ± 0.037 for D-6. Higher heat capacity changes, ranged from 0.246 ± 0.027 to 0.376 ± 0.018, were observed in the case of second glass transition (ΔC p2). It is well recognised the heat capacity is determined by both composition and mass. It is also known that ΔC p decreases when strong crosslinkages or intermolecular hydrogen bonds or weaker van der Waals forces increase in the system, restraining the chain mobility and increasing the stiffness of the polymer chains [38, 39].

Analysed β-LG–vitamin D3–carbohydrates complexes were characterised by low water content below 4.2 %, which is acceptable for such type of products in powdered form (Table 4). The water activity of studied complexes ranged from 0.167 to 0.193. In the case of β-LG–vitamin D3 complex, without carbohydrates addition, obtained by spray drying in the same conditions (air inlet temperature: 120 °C, flow rate: 51.4 mL min−1) (D7), water activity was significantly higher (Table 4). Powdered complexes of β-LG–vitamin D3–carbohydrates obtained by spray drying were characterised by a small particle size, very good wettability and solubility, independently on chemical composition. Lower values of particle size was observed for powdered β-LG–vitamin D3–lactose/maltodextrin (D1–D3) complexes. The effect of maltodextrin addition on particle size of powdered complexes was unclear. β-LG–vitamin D3 complex (D7), without carbohydrates addition, was characterised by similar values of water content, particle size and solubility index as its analogues containing lactose/maltodextrin and trehalose/maltodextrin systems (D1–D6). Wettability of β-LG–vitamin D3 complex was significantly poorer than in the case of products D1–D6. The powder D7 was characterised by wetting time longer than 15 s, which indicates that the complex does not possess characteristics of “instant’’ product contrary to samples D1–D6 (Table 4).

Water activity plays an important role in glass transition and crystallization behaviour of amorphous powders that determine their caking, flowability, stickiness and storage stability [1]. Moisture sorption isotherms illustrate the steady-state amount of water held by the food solids as a function of a w or %RH at constant temperature [40]. Moisture vapour sorption of foods depends on many factors, including chemical composition, physical–chemical state of the ingredients and physical structure. Figure 2 shows the sorption isotherm curves obtained for powdered complexes at a temperature of 25 °C. In the case of presented curves, the sigmoid shape typical of most food materials and high molecular weight hydrophilic polymers can be observed. The amount of maltodextrin in powdered complexes had no influence on shape of water vapour isotherms. Sorption isotherms of powdered complexes with lactose as a main component showed a dramatic decrease in sorbed water at water activity a w > 0.44 (Fig. 2a). This result is related to phase transformations of lactose, i.e. transition of the sugar from an amorphous to a crystalline state [41–43]. The amount of water sorbed by powdered β-LG–vitamin D3–trehalose/maltodextrin complexes (D4–D6) increased within full range of analysed water activity. Crystallization has not been observed for these products. This result is in agreement with studies presented by Sitaula and Bhowmick [44] who observed no crystallization in the case of trehalose–PBS (phosphate-buffered saline) mixtures. The amount of water sorbed by complexes containing lactose (D1–D3) was lower comparing to those with trehalose (D4–D6), in the range of a w from 0.44 to 0.92. The previous study showed that powdered β-LG–vitamin D3 complex without carbohydrates addition sorbed much more water than its analogues containing carbohydrates. Additionally, no decrease in sorbed water was observed in the shape of moisture sorption isotherm for β-LG–vitamin D3 complex without carbohydrates.

Adsorption kinetics of β-LG–vitamin D3–carbohydrates complexes is presented in Fig. 3. Higher water adsorption within 24 h was observed for powdered β-LG–vitamin D3–trehalose/maltodextrin complexes (D4–D6), independently on environmental water activity. In the case of β-LG–vitamin D3 complex the tendency to water sorption was much higher than for its analogues containing lactose/maltodextrin and trehalose/maltodextrin systems. At low water activity (a w 0.33) all powdered complexes showed typical sorption behaviour of food systems (Fig. 3a, b). Lactose crystallization observed at water activity 0.65 was affected by the maltodextrin presence in powdered complexes (Fig. 3c). This observation is in agreement with results obtained by Potes and Roos [45]. Trehalose as a main carbohydrate component of powdered complexes D4–D6, in comparison to lactose, reduced the occurrence of crystallization. In the case of β-LG–vitamin D3–trehalose/maltodextrin complex (D6), with trehalose/maltodextrin ratio 7:3, no crystallization within 24 h at water activity of 0.65 (Fig. 3d) was observed. Addition of the polymer, to an amorphous matrix, has been found to delay crystallization by reducing the crystal growth rate. The loss of adsorbed water at water activity of 0.65 in β-LG–vitamin D3 complexes with lactose/maltodextrin or trehalose/maltodextrin matrices is the result of carbohydrates crystallization. Crystallization of carbohydrates is a time-dependent process, which may occur from an amorphous state formed by spray drying [41]. Crystallization properties of lactose and trehalose are quite different [46]. It was observed that crystallization in powdered complexes with trehalose was delayed in comparison to powdered complexes containing lactose. At a w 0.92, crystallization of lactose or trehalose—the components of powdered complexes have not been observed (Fig. 3e, f). In general, at a w 0.92 the final water content of spray-dried powdered complexes increased with increasing maltodextrin concentration.

Conclusions

β-LG has been reported to be capable of binding a variety of fat-soluble ligands, including vitamin D3. The importance of the binding property is that it is possible to deliver vitamin D3 using β-LG as a carrier without the presence of the fat in which it normally associates. In order to provide optimal protection to β-LG during spray drying, to decrease stickiness and improve shelf life of the final products, trehalose and lactose were combined with maltodextrin and added to complexes. For the samples tested, it was possible to find two glass transitions well separated. The obtained results show that glass transition temperatures vary depending on the composition of studied complexes. The T g values were increased with increasing maltodextrin content. This was due to high molecular weight of maltodextrin. The glass transition temperature depended primarily on molecular weight; therefore, maltodextrins addition could be beneficial for improvement of final product stability. Sorption isotherm curves obtained for powdered complexes at a temperature of 25 °C showed the sigmoid shape typical of most food materials and high molecular weight hydrophilic polymers. Higher water adsorption within 24 h was observed for powdered β-LG–vitamin D3–trehalose/maltodextrin complexes, independently on environmental water activity. The addition of maltodextrin to food systems could improve the quality of the powders by delaying crystallization. It is of great importance because the extent of crystallization critical to acceptance of the final product powdered complexes of β-LG–vitamin D3–carbohydrates obtained by spray drying was characterised by a small particle size, very good wettability and solubility, independently on chemical composition.

References

Shrestha AK, Howes T, Adhikari BP, Wood BJ, Bhandari BR. Effect of protein concentration on the surface composition, water sorption and glass transition temperature of spray-dried skim milk powders. Food Chem. 2007;104:1436–44.

Bhandari BR, Howes T. Implication of glass transition for the drying and stability of dried foods. J Food Eng. 1999;40:71–9.

Roos YH. Thermal analysis, state transitions and food quality. J Therm Anal Calorim. 2003;71:197–203.

Roos YH. Phase transitions in foods. San Diego: Academic Press; 1995. p. 73–192.

Jakubczyk E, Ostrowska-Ligęza E, Gondek E. Moisture sorption characteristics and glass transition temperature of apple puree powder. Int J Food Sci Technol. 2010;45:2515–23.

Haque M, Roos Y. Water sorption and plasticization behaviour of spray-dried lactose/protein mixtures. J Food Sci. 2004;69(8):384–91.

Kasapis S. Definition and applications of the network glass transition temperature. Food Hydrocolloid. 2006;20:218–28.

Zeng JL, Yu SB, Cao Z, Yang DW, Sun LX, Znahg L, Zhang XF. Synthesize, crystal structure, heat capacities and thermodynamic properties of a potential enantioselective catalyst. J Therm Anal Calorim. 2011;105:961–8.

Gill PS, Sauerbrunn SR, Reading M. Modulated differential scanning calorimetry. J Therm Anal Calorim. 1993;40:931–9.

Reading M, Elliott D, Hill VL. MDSC, a new approach to the calorimetric investigation of physical and chemical transitions. J Therm Anal. 1993;40:949–55.

Reading M. Modulated differential scanning calorimetry—a new way forward in materials characterisation. Trends Polym Sci. 1983;1:248–53.

Labuza T. Sorption phenomena in foods. Food Technol. 1968;22:263–72.

Foster K, Bronlund J, Paterson A. The prediction of moisture sorption isotherms for dairy powders. Int Dairy J. 2005;15:411–8.

Furmaniak S, Terzyk A, Gołembiewski R, Gauden P, Czepirski L. Searching the most optimal model of water sorption on foodstuffs in the whole range of relative humidity. Food Res Int. 2009;42:1203–14.

Brownlow S, Cabral JHM, Cooper R, Flower DR, Yewdall SJ, Polikarpov I, North AC, Sawyer L. Bovine β-lactoglobulin at 1.8 Å resolution—still an enigmatic lipocalin. Structure. 1997;5(4):481–95.

Papiz MZ, Sawyer L, Eliopoulos EE, North AC, Findlay JB, Sivaprasadarao R, Jones TA, Newcomer ME, Kraulis PJ. The structure of beta-lactoglobulin and its similarity to plasma retinol-binding protein. Nature. 1986;324(6095):383–5.

Kontopidis G, Holt C, Sawyer L. Invited review: β-lactoglobulin: binding properties, structure, and function. J Dairy Sci. 2004;87:785–96.

Sawyer L, Kontopidis G. Review: the core lipocalin, bovine β-lactoglobulin. Biochim Biophys Acta. 2000;1482:136–48.

Mermelstein N. Spray drying. Food Technol. 2001;55(4):92–5.

Reineccius GA. Flavor encapsulation. Food Rev Int. 1989;5(1):146–76.

Carpenter JF, Manning MC. Rational design of stable protein formulations: theory and practice. Norwell: Kluwer Academic/Plenum Publishers; 2002.

Broadhead J, Edmond Rouan SK, Rhodes CT. The spray drying of pharmaceuticals. Drug Dev Ind Pharm. 1992;18(11):1169–206.

De Wit JN. Structure and functional behavior of whey proteins. Neth Milk Dairy J. 1981;35:47–64.

Murray BS, Liang HJ. Evidence for conformational stabilization of β-lactoglobulin when dried with trehalose. Langmuir. 2000;16:6061–3.

Patist A, Zoerb H. Preservation mechanisms of trehalose in food and biosystems. Colloids Surf B. 2005;40:107–13.

DePaz RA, Dale DA, Barnett CC, Carpenter JF, Gaertner AL, Randolph TW. Effects of drying methods and additives on the structure, function, and storage stability of subtilisin: role of protein conformation and molecular mobility. Enzyme Microb Technol. 2002;31:765–74.

Rahman M, Al-Marhubi I, Al-Mahrouqi A. Measurement of glass transition temperature by mechanical (DMTA), thermal (DSC and MDSC), water diffusion and density methods: a comparison study. Chem Phys Lett. 2007;440:372–7.

Szulc K, Lenart A. Effect of agglomeration on flowability of baby food powders. J Food Sci. 2010;75:E276–84.

Szulc K, Lenart A. Water vapour adsorption properties of agglomerated baby food powders. J Food Eng. 2012;109:135–41.

Jinapong N, Suphantharika M, Jamnong P. Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. J Food Eng. 2008;84:194–205.

IDF, International IDF Standard 129. Dried milk and dried milk products. Determination of insolubility index. 2005; (ISO 8156:2005)

Spiess WEL, Wolf W. Critical evaluation of methods to determine moisture sorption isotherms. In: Rockland LB, Beuchat LR, editors. Water activity: theory and applications to Food. New York: CRC Press; 1987. p. 215–43.

Allison SD, Chang B, Randolph TW, Carpenter JF. Hydrogen bonding between sugar and protein is responsible for inhibition of dehydration-induced protein unfolding. Arch Biochem Biophys. 1999;365:289–98.

Sacha GA, Nail SL. Thermal analysis of frozen solutions: multiple glass transitions in amorphous systems. J Pharm Sci. 2009;98(9):3397–405.

Górska A, Ostrowska-Ligęza E, Szulc K, Wirkowska M. A differential scanning calorimetric study of β-lactoglobulin and vitamin D3 complexes. J Therm Anal Calorim. 2012;110(1):473–7.

Sonthipermpoon W, Suwonsichon T, Wittaya-Areekul S, Wuttijumnong P. Effect of maltodextrin on glass transition temperature and water activity of production banana flake. Nat Sci. 2006;40:708–15.

Roos YH, Karel M. Phase transitions of mixtures of amorphous polysaccharides and sugars. Biotechnol Prog. 1991;7:49–53.

Donth EJ. Relaxation and thermodynamics in polymers: glass transition. Berlin: Akademie Verlag GmbH; 1992. p. 207–13.

Van Krevelen DW. Properties of polymers. Amsterdam: Elsevier; 1997. p. 71–8.

Labuza TP. Sorption phenomena in foods. J Food Technol. 1968;22:263–72.

Haque KMD, Roos YH. Water plasticization and crystallization of lactose in spray-dried lactose/protein mixtures. J Food Sci. 2004;69:FEP23–9.

Debnath S, Hemavathy J, Bhatb KK. Moisture sorption studies on onion powder. Food Chem. 2002;78:479–82.

Tomas M, Scher J, Desobry S. Study of lactose/β-lactoglobulin interactions during storage. Lait. 2005;85:325–33.

Sitaula R, Bhowmick S. Moisture sorption characteristics and thermophysical properties of trehalose-PBS mixtures. Cryobiology. 2006;52:369–85.

Potes N, Roos YH. Crystallization in amorphous lactose-maltodextrin mixtures. 11th International Congress on Engineering and Food, May 22–26. Athens, FMS198; 2011.

Miao S, Ross YH. Crystallization kinetics and X-ray diffraction of crystals formed in amorphous lactose, trehalose, and lactose/trehalose mixtures. J Food Sci. 2005;70(5):E350–8.

Acknowledgements

This work was supported by the Ministry of Science and Higher Education Grant No. N N312 068639.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Górska, A., Szulc, K., Ostrowska-Ligęza, E. et al. The influence of trehalose–maltodextrin and lactose–maltodextrin matrices on thermal and sorption properties of spray-dried β-lactoglobulin–vitamin D3 complexes. J Therm Anal Calorim 112, 429–436 (2013). https://doi.org/10.1007/s10973-013-2980-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-2980-z