Abstract

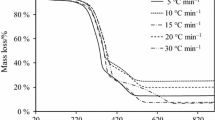

This study evaluates the thermal behavior of bagasse malt fresh and its heat capacity by means of calorimetry for samples with different moisture contents (50, 40, 30, 20, and 15 %). Chemical analysis was used to determine the content of volatiles, fixed carbon, and ash. The thermal degradation of malt bagasse presents two mass loss steps attributed to the release of moisture and to the decomposition of organic material. The calorific value of bagasse malt showed variation with moisture reduction as expected. Also showed variation with density. It was found a high percentage of volatile materials and the low percentage of ash and fixed carbon.

Similar content being viewed by others

References

Villanueva M, Proupín J, Rodríguez-Añón JA, Fraga-Grueiro L, Salgado J, Barros N. Energetic characterization of forest biomass by calorimetry and thermal analysis. J Therm Anal Calorim. 2011;104:61–7.

Mothé CG, Miranda IC. Characterization of sugarcane and coconut fibers by thermal analysis and FTIR. J Therm Anal Calorim. 2009;97:661–5.

Munir S, Daood SS, Nimmo W, Cunliffe AM, Gibbs BM. Thermal analysis and kinetics of cotton stalk, sugar cane bagasse and shea meal under nitrogen and air atmospheres. Biosource Technol. 2009;100:1413–8.

Ion IV, Popescu F, Rolea GG. A biomass pyrolysis model for CFD application. J Therm Anal Calorim. 2012. doi:10.1007/s10973-012-2552-7.

Yaman S. Pyrolysis of biomass to produce fuels and chemical feedstocks. Energy Convers Manag. 2004;45:651–71.

Ozbay N, Putun AE, Uzun BB, Putun E. Biocrude from biomass: pyrolysis of cottonseed cake. Renew Energy. 2001;24:615–25.

Buryan P, Staff M. Pyrolysis of the waste biomass. J Therm Anal Calorim. 2008;93:637–40.

Nocun′-Wczelik W, Bochenek A, Migdał M. Calorimetry and other methods in the studies of expansive cement hydrating mixtures. J Therm Anal Calorim. 2012. doi:10.1007/s10973-012-2379-2.

Santos MS, Ribeiro FM. Cervejas e Refrigerantes. São Paulo: CETESB; 2005. p. 58.

Costa AD, Mattos ES, Lima CAR, Vieira AA, Mattos MA, Ferreira RAD, Sarinho VC, Ramalho HF. Composição química e energia digestível do bagaço de malte em suínos machos nas fases de crescimento e terminação. Seropédica: Anais da Jornada de Iniciação Científica da UFRRJ; 2006.

Lima ML. Resíduo de cervejaria úmido: formas de conservação e efeitos sobre parâmetros ruminais. Piracicaba. Dissertação (Mestrado em Ciência Animal e Pastagens)—Universidade de São Paulo, Piracicaba; 1993. p. 98.

Silva JBA. Perspectivas biotecnológicas de aproveitamento de bagaço de malte. V Simpósio Latino Americano de Cevada, Malte e Malteação. Escola de Engenharia de Lorena. Universidade de São Paulo, Lorena-SP. 2010.

Brasil. Ministério da Saúde. Agência Nacional de Vigilância Sanitária. Métodos Físico-Químicos para Análise de Alimentos/Ministério da Saúde, Agência Nacional de Vigilância Sanitária. Brasília: Ministério da Saúde; 2005. p. 1018.

ABNT—Associação Brasileira de Normas Técnicas. NBR 8633/84–Carvão vegetal–Determinação do poder calorífico. p. 13.

ASTM D240 standard test method for heat of combustion of liquid hydrocarbon fuels by bomb calorimeter.

ASTM D3286-96 standard test method for gross calorific value of coal and coke by the isoperibol bomb calorimeter.

ASTM. American Society for Testing and Materials. D 1762-64 (Reapproved 1977).

ABNT–Associação Brasileira de Normas Técnicas. NBR 8112/83–Carvão vegetal–Análise imediata; 1983. p. 6.

Vale AT, Mendes RM, Amorim MRS, Dantas VFS. Potencial energético da biomassa e carvão vegetal do epicarpo e da torta de pinhão manso (Jatropha curcas). Cerne Lavras. 2011;17(2):267–73.

Brito JO, Barrichelo LEG. Carvão vegetal de madeira de desbaste de Pinus. Circ Técnica IPEF Piracicaba. 1982;146:1–12.

Acknowledgements

The authors acknowledge the Universidade Federal of Paraíba for the instrumental support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cordeiro, L.G., El-Aouar, Â.A. & de Araújo, C.V.B. Energetic characterization of malt bagasse by calorimetry and thermal analysis. J Therm Anal Calorim 112, 713–717 (2013). https://doi.org/10.1007/s10973-012-2630-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2630-x