Abstract

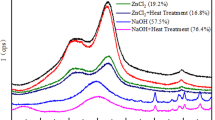

Moso bamboo (Phyllostachys pubescens) and sinocalamus affinis (Phyllostachys heterocycla) were used in the research. Thermogravimetry (TG), a combination of TG and Fourier transform infrared spectrometer (TG–FTIR), X-ray diffraction (XRD), and differential thermal analysis (DTA) were used to investigate thermal decomposition of bamboo. The calorific value and smoke release process of both bamboos were also tested, respectively. The results from TG indicated that degradation process of sinocalamus affinis and moso bamboo was similar, but their degradation temperatures were different. The main decomposition occurred in the second step and about 68.70 and 64.63% masses degraded for sinocalamus affinis and moso bamboo, whose temperature of maximum mass loss was 319 and 339 °C, respectively. DTA curve showed that the thermal decomposition of both bamboos was an absorbance heat process. TG–FTIR analysis showed that the main pyrolysis products of both bamboos were similar, including absorbed water (H2O), methane gas (CH4), carbon dioxide (CO2), acids and aldehydes, ammonia gas (NH3). The calorific value of moso bamboo (19,291 J g−1 K−1) was higher than that of sinocalamus affinis (18,082 J g−1 K−1). The initial time of smoke release process of moso bamboo was later, and its maximum smoke density was higher than that of sinocalamus affinis. The difference was probably attributed to different compositions and structure of sinocalamus affinis and moso bamboo. The results from this research are very helpful to better design manufacturing process of bio-energy, made from bamboo, by gasification and pyrolysis methods.

Similar content being viewed by others

References

Jiang ZH. World bamboo and rattan. China: Liaoning Science & Technology Press; 2002.

Travis F, Mohammad H, Bruce W, Diane K. Pyrolysis behavior and kinetics of biomass derived materials. J Anal Appl Pyrolysis. 2002;62:331–49.

Castelló ML, Dweck J, Aranda DAG. Kinetic study of thermal processing of glycerol by thermogravimetry. J Therm Anal Calorim. 2011;105:737–46.

Anker J, Kim DJ. TG–FTIR study of the influence of potassium chloride on wheat straw pyrolysis. Energy Fuels. 1998;12:929–38.

Robertis ED, Moreira GF, Silva RA, Achete CA. Thermal behavior study of biodiesel standard reference materials. J Therm Anal Calorim. 2011;106:347–54.

Teixeira KC, Moreira GF, Quirino WG, Legnani C, Silva RA, Cremona M, Brito HF, Achete CA. TG–FTIR thermal stability investigation of tetrakis beta-diketonates complexes. J Therm Anal Calorim. 2011;106:587–93.

Shoval S, Nathan Y. Analyzing the calcination of sulfur-rich calcareous oil shales using FT-IR spectroscopy and applying curve-fitting technique. J Therm Anal Calorim. 2011;105:883–96.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to phenolic plastic. J Polym Sci C. 1964;6:183–95.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand. 1956;57:217–21.

Flynn JH, Wall LA. General treatment of thermogravimetry of polymers. J Res Natl Bur Stand Sect A. 1966;A70:487–523.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–7.

Brown ME, Maciejewski M, Vyazovkin S, Nomen R, Sempere J, Burnham A. Computational aspects of kinetic analysis. Part A: the ICTAC kinetics project-data, methods and results. Thermochim Acta. 2000;355:125–43.

Doyle CD. Kinetic analysis of thermogravimetric data. J Appl Polym Sci. 1961;15:285–92.

Bradbury AW, Sakai Y, Shafizadeh F. A kinetic model for pyrolysis of cellulose. J Appl Polym Sci. 1979;23:3271–80.

Koufopanos CA, Maschio G, Lucchesi A. Kinetic modeling of the pyrolysis of biomass and biomass components. Can J Chem Eng. 1989;67:75–84.

Yao F, Wu QL, Lei Y, Guo WH, Xu YJ. Thermal decomposition kinetics of natural fibers: activation energy with dynamic thermogravimetric analysis. Polym Degrad Stab. 2008;93:90–8.

Jin PK, Zou XG. Investigation on kinetic of bamboo pyrolysis. Energy Conserv. 2008;6:20–2.

Li WZ, He YJ, Chen P. The factors influencing the characteristics of bamboo pyrolysis, a hot analytic approach. J Bamboo Res. 2006;2:31–5.

Hill AC. Wood modification. USA: Wiley; 2006. p. 25.

Bourgois J, Bartholin MC, Guyonnet R. Thermal treatment of wood: analysis of the obtained product. Wood Sci Technol. 1989;23:303–10.

Nassar MM, Mackay GD. Mechanism of thermal decomposition of lignin. Wood Fiber Sci. 1984;16:441–53.

Zhou HS, Zhong EY. Development and application of bamboo fiber. Text Sci Res. 2003;4:30–7.

Jiang ZH, Yu WJ, Yu YL. Analysis of chemical components of bamboo and characteristics of surface performance. J Northeast For Univ. 2006;4:1–3.

Mészáros E, Jakab E, Várhegyi G. TG/MS, Py-GC/MS and THM-GC/MS study of the composition and thermal behavior of extractive components of Robinia pseudoacacia. J Anal Appl Pyrolysis. 2007;79:61–70.

Shafizadeh F, Milne RP, Mudge LK. Fundamentals of thermochemical biomass conversion. London: Elsevier Applied Science Publishers; 1985.

Le Van SL. Thermal degradation. In: Schniewind AP, editor. Concise encyclopedia of wood and wood-based materials. New York: Elmsford; 1989.

Telmo C, Lousada J. Heating values of wood pellets from different species. Biomass Bioenergy. 2011;35:2634–9.

Acknowledgements

This research was financially supported by ‘Basic Scientific Research Funds of International Centre for Bamboo and Rattan’ (Grant No. 1632012002) and ‘Development and demonstration of bamboo/wood composite LVL and wallboard’ (Grant No. [2008] 16)

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, Z., Fei, B., Jiang, Z. et al. A comparative study of thermal properties of sinocalamus affinis and moso bamboo. J Therm Anal Calorim 111, 393–399 (2013). https://doi.org/10.1007/s10973-012-2266-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2266-x