Abstract

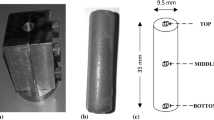

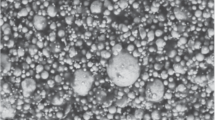

The objective of this work is to study the sintering behavior of polyamide 6 (PA6) powders and PA6 nanocomposites by means of thermomechanical (TMA) and dimensionless analysis in view of its technological application in rotational molding. TMA analysis was used to monitor the bulk density evolution of PA6 powders and PA6 nanocomposites when heated above the melting temperature. Experimental TMA results indicate that the sintering of PA6 and PA6 nanocomposites occurs in two different steps, namely powder coalescence and void removal. Furthermore, TMA analysis showed that relevant degradation phenomena occur during the sintering of PA6 and PA6 nanocomposites, leading to gas formation in the molten polymer. The suitability of these materials in rotational molding was then assessed by defining a processing window, as the temperature difference between the endset sintering and the onset degradation. The heating rate dependence of the processing window was explained by means of dimensionless analysis, showing that powder coalescence is influenced by the viscosity evolution of the matrix, whereas void removal is influenced by the gas diffusivity inside the molten matrix. Therefore, the diffusion activation energy correlates the endset sintering temperature to the heating rate. On the other hand, the onset degradation temperature depends on the heating rate, due to the characteristic activation energy of the degradation process. Accordingly, the width of the processing window mainly depends on the values of the activation energies for diffusivity and degradation. The width of the processing window for neat PA6 was found to be too narrow to candidate this polymer for rotational molding. The addition of nanofiller causes a narrowing of the processing window, whereas the PA6 matrix modified with a thermal stabilizer showed a sufficiently broad processing window, compatible for use in rotational molding.

Similar content being viewed by others

References

Kandis M, Bergman TL. Observation, prediction, and correlation of geometric shape evolution induced by non-isothermal sintering of polymer powder. J Heat Transf-Trans ASME. 1997;119:824–31.

Liu SJ. International polymer processing XIII. Munich: Hanser Publishers; 1998.

Bellehumeur CT, Bisaria MK, Vlachopoulos J. An experimental study and model assessment of polymer sintering. Polym Eng Sci. 1996;36:2198–207.

Kontopoulou M, Vlachopoulos J. Bubble dissolution in molten polymers and its role in rotational molding. Polym Eng Sci. 1999;39:1189–98.

Greco A, Maffezzoli A. Polymer melting and polymer powder sintering by thermal analysis. J Therm Anal Calorim. 2003;72:1167–74.

Greco A, Maffezzoli A. Powder-shape analysis and sintering behavior of high-density polyethylene powders for rotational molding. J Appl Polym Sci. 2004;92:449–60.

Bellehumeur CT, Kontopulou M, Vlachopoulos J. The role of viscoelasticity in polymer sintering. Rheol Acta. 1998;37:270–8.

Kontopoulou M, Vlachopoulos J. Melting and densification of thermoplastic powders. Polym Eng Sci. 2001;41:155–69.

Gogos G. Bubble removal in rotational molding. Polym Eng Sci. 2004;44:388–94.

Rezaei M, Ebrahimi NG, Kontopoulou M. Thermal properties, rheology and sintering of ultra high molecular weight polyethylene and its composites with polyethylene terephthalate. Polym Eng Sci. 2005;45:678–86.

Drummer D, Rietzel D, Kuhnlein F. Development of a characterization approach for the sintering behavior of new thermoplastics for selective laser sintering. Phys Procedia. 2010;5:533–42.

Kim J, Creasy TS. Selective laser sintering characteristics of nylon 6/clay-reinforced nanocomposite. Polym Test. 2004;23:629–36.

Chung H, Das S. Functionally graded nylon-11/silica nanocomposites produced by selective laser sintering. Mater Sci Eng. 2008;487:251–7.

Salmoria GV, Leite JL, Paggi RA. The microstructural characterization of PA6/PA12 blend specimens fabricated by selective laser sintering. Polym Test. 2009;28:746–51.

Dong L, Makradi A, Ahzi S, Remond Y, Sun X. Simulation of the densification of semicrystalline polymer powders during the selective laser sintering process: application to nylon 12. Polym Sci Ser A. 2008;50:704–9.

Asgarpour M, Bakir F, Khelladi S, Khavandi A, Tcharkhtchi A. Characterization and modeling of sintering of polymer particles. J Appl Polym Sci. 2001;119:2784–92.

Jain PK, Pandey PM, Rao PVM. Selective laser sintering of clay-reinforced polyamide. Polym Compos. 2010;31:732–43.

Oliveira MJ, Cramez MC, Garcia CB, Kearns MP, Maziers E. Effect of the processing conditions on the microstructure and properties of rotational molded polyamide 11. J Appl Polym Sci. 2008;108:939–46.

Opfermann J, Blumm J, Emmerich WD. Simulation of the sintering behavior of a ceramic green body using advanced thermokinetic analysis. Thermochim Acta. 1998;318:213–20.

Greco A, Strafella A, La Tegola C, Maffezzoli A. Assessment of the relevance of sintering in thermoplastic commingled yarn consolidation. Polym Compos. 2011;32(4):657–64.

Dealy JM, Larson RG. Structure and rheology of molten polymers. Munich: Carl Hanser Verlag; 2006.

Ojovan MI, Lee WE. Fragility of oxide melts as a thermodynamic parameter. Phys Chem Glasses. 2005;46(1):7–11.

Vogel H. The law of temperature dependence of the viscosity of fluids. Phys Z. 1921;22:65.

Greco A, Maffezzoli A, Vlachopoulos J. Simulation of heat transfer during rotational molding. Adv Polym Tech. 2003;22:271–9.

Shah RK, Paul DR. Organoclay degradation in melt processed polyethylene nanocomposites. Polymer. 2006;47:4075–84.

Esposito Corcione C, Cavallo A, Pesce E, Greco A, Maffezzoli A. Evaluation of the degree of dispersion of nanofillers by mechanical, rheological, and permeability analysis. Polym Eng Sci. 2011;51:1280–5.

Esposito Corcione C, Mensitieri G, Maffezzoli A. Analysis of the structure and mass transport properties of nanocomposite polyurethane. Polym Eng Sci. 2009;49:1708–18.

Son Y. Measurement of interfacial tension between polyamide-6 and poly(styrene-co-acrylonitrile) by breaking thread method. Polymer. 2001;42:1287–91.

Van Krevelen DW, te Nijenhuis K. Properties of polymers. 4th ed. Amsterdam: Elsevier; 2009.

Acknowledgements

Authors wish to thank the “Regione Puglia” for financial support of the project “INCOR—Innovative thermoplastic matrix composites for rotational moulding”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Greco, A., Maffezzoli, A., Calò, E. et al. An investigation into sintering of PA6 nanocomposite powders for rotational molding. J Therm Anal Calorim 109, 1493–1502 (2012). https://doi.org/10.1007/s10973-011-1916-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-1916-8