Abstract

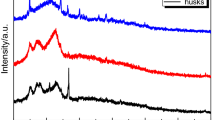

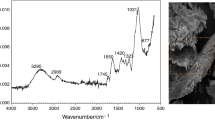

The increase in sugarcane production and processing in order to obtain important products such as sugar and ethanol has the negative aspect of also increasing industrial residues. The most important residues originated during processing are bagasse, hydrolyzed bagasse, filter cake, vinasse, and ash. Thermal analysis revealed that these residues have peculiar properties, such as the presence of lignocellulosic material, except in the ash. The amount of organic matter decreases during the treatment process, due to the addition of chemical products to the residues, which are responsible for some alteration in their thermal properties. Colorimetric analysis showed considerable K and P concentrations in the vinasse and filter-cake residues. EDX and infrared spectroscopy showed the presence of Si in the residues. A higher percent of Si in ash sample was also observed, as a product of the thermal decomposition, by TG, FTIR, and X-ray diffractometry.

Similar content being viewed by others

References

Zardo AM, et al. Utilização da cinza de bagaço cana-de-açúcar como “filler” em compostos de fibrocimento. In: Conferência Latino-Americana de Construção Sustentável, 10., 2004; Encontro Nacional de Tecnologia, 1.,2004. São Paulo: Anais. São Paulo; 2004.

Piacente EA, Piacente FJ. Agricultura para um desenvolvimento sustentável: cana-de-açúcar. In: Seminário Internacional Ciência e Tecnoçogia na América Latina, 1., 2004. Campinas: Resumos… Campinas UNICAMP; 2004. p. 25.

Cortez L, Magalhães P. Principais subprodutos da agroindústria canavieira e sua valorização. Revista Brasileira de Energia. 1992;2:1–17.

Oliveira ER. Fiscalização de laboratórios de análise da qualidade da cana-de-açúcar. Piracicaba: Orplana; 2006. (1 CD––ROM).

Ramalho JFGP, Amaral Sobrinho NMB. Metais pesados em solos cultivados com cana de açúcar pelo uso de resíduos agroindustriais. Revista de Floresta e Ambiente. 2001;8:120–9.

CETESB Technique Norm P4.231 (Norma Técnica P4.231/2006).

Ernesto VART, Ribeiro CA, Hojo O, Fertonani FL, Crespi MS. Thermal characterization of lignocellulosic residue from different sugarcanes. J Therm Anal Calorim. 2009;97:653–6.

Silva AR, Crespi MS, Ribeiro CA, Oliveira SC, Silva MRS. Kinetic of thermal decomposition of residues from different kinds of composting. J Therm Anal Calorim. 2004;75:401–9.

Dell’Abate MT. Thermal methods of organic matter maturation monitoring during a composting process. J Therm Anal Calorim. 2000;61:389–96.

Almeida S, Lima EN, Crespi MS, Ribeiro CA, Schalch V. Kinetic studies of urban solid and leachate from sanitary landfill. J Therm Anal Calorim. 2009;97:529–33.

Acknowledgements

The authors are grateful to CNPq and FAPESP for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Crespi, M.S., Martins, Q.V., de Almeida, S. et al. Characterization and thermal behavior of residues from industrial sugarcane processing. J Therm Anal Calorim 106, 753–757 (2011). https://doi.org/10.1007/s10973-011-1397-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-1397-9