Abstract

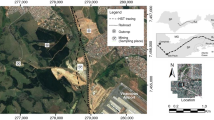

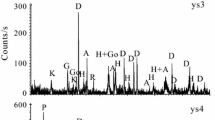

This article studied the thermal behavior and the evolution of the crystalline phases with temperature of the red mud (bauxite tailing) from an aluminum industry at Maranhão, North-Northwestern Brazil. The experiments were carried out by Field Emission Scanning Electron Microscopy (FE-SEM), Simultaneous Thermal Analysis (TG–DSC), Optical Dilatometry up to 1623 K, and X-ray diffraction (XRD) of previously heated samples between 523 and 1523 K. The crystalline phases and the amorphous contents were quantified on raw and heated samples (at 1523 K) according to the Rietveld Quantitative Analysis (RQA) method. The data obtained showed that the raw red mud is composed by a mixture of seven different phases (hematite, goethite, sodalite, anatase, gibbsite, calcite, and amorphous). Finally in the interval of 1023–1523 K the following crystalline phases: hematite, nepheline, sodalite, anatase, perovskite, and pseudobrookite have been observed.

Similar content being viewed by others

References

Bray EL. Bauxite and alumina. In: Survey USG, editor. Mineral commodity summaries 2008. Washington: US Geological Survey; 2008. p. 32.

Bayer KJ. 1972. German Patent No: 2150677.

Hall CM. 1889. US Patent No: 400766.

Heroult R. 1886. French Patent No: 175 711.

Authier-Martin M, Forté G, Ostap S, See J. The mineralogy of bauxite for producing smelter-grade alumina. JOM. 2001;53:36–40.

Hinda AR, Bhargava SK, Grocott SC. The surface chemistry of Bayer process solids: a review. Colloids Surf A Physicochem Eng Asp. 1999. doi:10.1016/S0927-7757(98)00798-5.

Thakur RS, Saint BR. Utilization of red mud-part I. J Sci Ind Res. 1974;33:403–512.

Departamento Nacional de Produção Mineral: Brazilian Mineral data base. 2010. www.dnpm.gov.br. Accessed 30 Mar 2010.

Motta Sobrinho MA, Alves MCM, Silva Filho EB. Lama vermelha da indústria de beneficiamento de alumina: produção, características, disposição e aplicações alternativas. Revista Matér. 2007;12:322–38.

Glenister D, Smirk D, Piskersgil G. Bauxite residue-development of a resource. In: Proceedings of the international bauxite tailings workshop, Perth, Western Australia; 1992. p. 301–8.

Paranguru RK, Rath PC, Misra VN. Trends in red mud utilization—a review. Min Process Extr Metall Rev. 2005. doi:10.1080/08827500490477603.

Associação Brasileira de Normas Técnicas—ABNT. NBR 10004: Resíduos sólidos—Classificação, Rio de Janeiro 2004.

Tauber E, Hill RK, Crook DN, Murray MJ. Red mud residues from alumina production as raw material for heavy clay products. J Aust Ceram Soc. 1971;7:12–7.

Knight JC, Wagh AS, Reid WA. The mechanical properties of ceramics from bauxite waste. J Mater Sci. 1986. doi:10.1007/BF00547967.

Moya JS, Morales F, Garcia AV. Utilizacion cerámica de los barros rojos de las plantas de alumina. Bol Soc Esp Cerám Vidr. 1987;26:21–9.

Morales F, Moya JS, De Aza SP. Obtención de ladrillos densos a partir de Barros Rojos, subproducto de las plantas de alúmina. In: Actas II del VIII Congreso-Exposición Argentino y II Iberoamericano de Cerámica, Vidrio y Refractarios, Buenos Aires; 1988. p. 117.

Pinnock WR, Gordon JN. Assessment of strength development in Bayer-process residues. J Mater Sci. 1992. doi:10.1007/BF02403881.

De La Gandara JLO, Alvarez P. La magnetita en la fabricación de ladrillos para la acumulación de calor. Rev Metal. 1994;30:135–44.

Gordon JN, Pinnock WR, Moore MM. A preliminary investigation of strength development in Jamaican red mud composites. Cem Conc Comp. 1996. doi:10.1016/S0958-9465(96)00027-3.

Rodriguez GAP, Rivera FG, De Aza SP. Obtención industrial de materiales cerámicos a partir de lodos rojos del proceso Bayer. Bol Soc Esp Cerám Vidr. 1999;38:220–6.

Sglavo VM, Campostrini R, Maurina S, Carturan G, Monagheddu M, Budroni G, Cocco G. Bauxite ‘red mud’ in the ceramic industry. Part 1: thermal behavior. J Eur Ceram Soc. 2000. doi:10.1016/S0955-2219(99)00088-6.

Sglavo VM, Maurina S, Conci A, Salviati A, Carturan G, Cocco G. Bauxite ‘red mud’ in the ceramic industry. Part 2: production of clay-based ceramics. J Eur Ceram Soc. 2000. doi:10.1016/S0955-2219(99)00156-9.

Alp A, Goral MS. The influence of soda additive on the thermal properties of red mud. J Therm Anal Calorim. 2003. doi:10.1023/A:102519792767.

Atasoy A. The comparison of the Bayer process waste on the base of chemical and physical properties. J Therm Anal Calorim. 2007. doi: 10.1007/s10973-005-7671-y.

Pascual J, Corpas FA, López-Beceiro J, Benítez-Guerrero M, Artiaga R. Thermal characterization of Spanish Red Mud. J Therm Anal Cal. 2009. doi: 10.1007/s10973-008-9230-9.

Palmer SJ, Frost RL. Thermal decomposition of Bayer precipitates formed at varying temperatures J Therm Anal Cal. 2010. doi:10.1007/s10973-009-0136-y.

Palmer SJ, Frost RL. Characterisation of bauxite and seawater neutralised bauxite residue using XRD and vibrational spectroscopic techniques. J Mater Sci. 2009. doi:10.1007/s10853-008-3123-y.

Rodríguez-Carvajal J. Recent advances in magnetic structure determination by neutron powder diffraction. Phys B Condens Matter. 1993. doi:10.1016/0921-4526(93)90108-I.

Smith P. The processing of high silica bauxites—review of existing and potential processes. Hydrometallurgy. 2009. doi:10.1016/j.hydromet.2009.04.015.

Snars K, Gilkes RJ. Evaluation of bauxite residues (red muds) of different origins for environmental applications. Appl Clay Sci. 2009. doi:10.1016/j.clay.2009.06.014.

Mackenzie RC. The differential thermal investigation of clays. London: Mineralogical Society; 1957. v. 1, cap. 12, 329–363.

Wefers K, Misra C. Oxides and hydroxides of aluminum. Pensilvania, USA: ALCOA, Laboratories; 1987. p. 20.

Ingram-Jones VJ, Slade RCT, Davies TW, Southern JC, Salvador S. Dehydroxylation sequences of gibbsite and boehmite: study of differences between soak and flash calcination and of particle-size effects. J Mater Chem. 1996. doi:10.1039/JM9960600073.

Rivas Mercury JM, De Aza AH, Turrillas X, Sheptyakov D, Pena, P. On the decomposition of synthetic Gibbsite studied by neutron thermodiffractometry. J Am Ceram Soc. 2006. doi:10.1111/j.1551-2916.2006.01191.x.

Derie R, Ghodsiand M, Calvo-Roche C. DTA study of the dehydration of synthetic goethite α-FeOOH. J Therm Anal Cal. 1976. doi:10.1007/BF01909409.

Šubrt J, Balek V, Criado JM, Pérez-Maqueda LA, Večerniková E. Characterisation of α-FeOOH grinding products using simultaneous DTA and TG/DTG coupled with MS. J Therm Anal Cal. 1998. doi:10.1023/A:1010197510542.

Laskoul M, Margomenou-Leonidopoulou G, Balek V. Thermal characterization of bauxite samples. J Therm Anal Cal. 2006. doi:10.1007/s10973-005-7126-5.

Alp A, Goral MS. The influence of soda additive on the thermal properties of red mud. J Therm Anal Cal. 2003. doi:10.1023/A:1025197927673.

Atasoy A. An investigation on the characterization and thermal analysis of the Aughinish red mud. J Therm Anal Cal. 2005. doi:10.1007/s10973-005-6419-z.

Todor DN. Thermal of mineral analysis. 1st ed. Bucharest: Abacus Press; 1976.

Bown WE, Dollimore D, Galvey AK. Reactions in the solid state: chemical kinetics, vol. 22, New York: Elsevier; 1980.

Whittington B, Ilievski D. Determination of the gibbsite dehydration reaction pathway at conditions relevant to Bayer refineries. Chem Eng J. 2004. doi:10.1016/S1385-8947(03)00207-9.

Gan BK, Madsen IC, Hockridge JG. In situ X-ray diffraction of the transformation of gibbsite to alumina through calcination: effect of particle size and heating rate. J Appl Cryst. 2009. doi:10.1107/S0021889809021232.

Mitov I, Paneva D, Kunev B. Comparative study of the thermal decomposition of iron oxyhydroxides. Thermochim Acta. 2002. doi:10.1016/S0040-6031(01)00808-5.

Armstrong JA, Dann SE. Investigation of zeolite scales formed in the Bayer process. Microporous Mesoporous Mater. 2000. doi:10.1016/S1387-1811(00)00276-6.

Borchert W, Keidel J. Reactivity of silicates at low temperatures: I. Heildelberg Beitr Mineral Petrogr. 1947;1:12–6.

Mead PJ, Weller MT. Synthesis, structure, and characterization of halate sodalites: M 8[AlSiO4]6(XO3)x(OH)2−x ; M = Na, Li, or K; X = Cl, Br, or I. Zeolites. 1995. doi:10.1016/0144-2449(95)00004-P.

Felsche J, Luger S. Phases and thermal decomposition characteristics of hydro-sodalites Na6+x,[AlSiO4]6,(OH)x·nH2O. Thermochim Acta. 1987. doi:10.1016/0040-6031(87)80069-2.

Schipper DJ, Lathouwers TJ, Van Doorn CZ. Thermal decomposition of sodalites. J Am Ceram Soc. 1973. doi:10.1111/j.1151-2916.1973.tb12402.x.

Acknowledgements

The authors wish to thank the Fundação ao Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) and Prof. Dr. José Anchieta Rodrigues at the Materials Engineering Department of The Federal University of São Carlos—São Paulo Brazil.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rivas Mercury, J.M., Cabral, A.A., Paiva, A.E.M. et al. Thermal behavior and evolution of the mineral phases of Brazilian red mud. J Therm Anal Calorim 104, 635–643 (2011). https://doi.org/10.1007/s10973-010-1039-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-1039-7