Summary

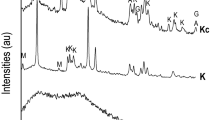

In this paper the optimization of the kaolin calcination is studied, aiming at using the produced metakaolin as supplementary cementitious material. Representative samples of poor Greek kaolin (Milos island) and a high purity commercial kaolin were tested. Samples were heated at different temperatures during different times. The optimization of calcination conditions was studied by DTA-TG and XRD analysis of the raw and thermal treated kaolin samples, by pozzolanic activity analysis of metakaolins and finally by strength development analysis of cement-metakaolin mixtures. This approach showed that heating at 650°C for 3 h is efficient to convert poor kaolins with low alunite content to highly reactive metakaolins. However in the case of kaolin with a high alunite content, thermal treatment at 850°C for 3 h is required in order to remove undesirable SO3. Evidence was found that poor kaolins can be efficiently used for the production of highly reactive metakaolins.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Badogiannis, E., Kakali, G. & Tsivilis, S. Metakaolin as supplementary cementitious material. J Therm Anal Calorim 81, 457–462 (2005). https://doi.org/10.1007/s10973-005-0806-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-005-0806-3