Abstract

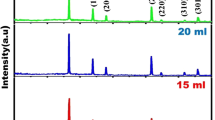

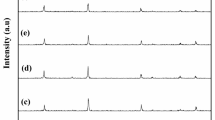

In the present paper, tin dioxide (SnO2) thin films had been fabricated with different precursor concentration in the range of 0.01–0.09 M onto amorphous glass substrates utilizing nebulizer spray method. The effect of precursor concentration on electrical, morphological, structural, optical, and photoluminescence properties has been investigated. XRD spectrum revealed that the polycrystalline nature of SnO2 thin films with tetragonal structure in the range of precursor concentration 0.03–0.09 M, which are having a favorable growth orientation along (110) direction. The estimated average crystallite size varied between 22 and 53 nm. UV-Visible spectrum exposes the transmittance of SnO2 thin films lies between 90 and 78% in the visible range. The direct band gap energy reduced from 3.83 to 3.71 eV on increasing precursor concentration upto 0.07 M and then it was further increased. Photoluminescence spectra at room temperature exhibited a strong peak at 362 nm with shoulder peak at 376 nm and two broad peaks are 493 nm and 518 nm. SEM analysis illustrated that the polyhedron-like grains were homogeneously arranged over the film surface. The film prepared at 0.07 M precursor concentration shows the least resistivity 2.41 × 10−3 Ω-cm and good figure of merit 16.41 × 10−3 (Ω/sq)−1.

Highlights

-

SnO2 thin films were deposited with different precursor concentration (0.01–0.09 M) using nebulized spray pyrolysis (NSP) technique.

-

Crystallite size in the range of 22–53 nm.

-

Transmittance decreased from 90 to 78% in the visible region.

-

Minimum electrical resistivity 2.41 × 10−3 Ω-cm obtained at 0.07 M precursor concentration.

-

Highest figure of merit is found to be 16.41 × 10−3 (Ω/sq)−1.

Similar content being viewed by others

References

Godbole VP, Vispute RD, Chaudhari SM, Kanetkar SM, Ogale SB (1990) J Mater Res 5:372–377

Phillips HM, Li Y, Bi Z, Zhang B (1996) Appl Phys A 63:347–351

Dolbec R, El Khakani MA, Serventi AM, Trudeau M, Saint-Jacques RG (2002) Thin Solid Films 419:230–236

Bagheri-Mohagheghi MM, Shokooh-Saremi M (2010) Phys B Condens Matter 405:4205–4210

Park JH, Lee JH (2009) Sens Actuators B 136:151–157

Pusawale SN, Deshmukh PR, Lokhande CD (2011) Appl Surf Sci 257:9498–9502

Zhang Y, Liu Y (2006) Chem Mater 18:4643–4646

Vaufrey D, Ben khalifa M, Besland MP, Sandu C, Balanchin MG, Teodorescu V (2002) Synth Met 127:207–211

Zaouk D, Zaatar Y, Khoury A, Llinares C, Charles JP, Bechara J (2000) Microelectron Eng 51-52:627–631

Kumar KDA, Valanarasu S, Kathalingam A, Jeyadheepan K (2018) Mater Res Bull 101:264–271

Seo J, Kim GW, Sung CH, Anwar MS, Lee CG, Koo BH (2011) Curr Appl Phys 11:S310–S313

Ebrahimiasl S, Yunus WMZW, Kassim A, Zainal Z (2011) Sensors 11:9207–9216

Zdenek M, Remes, Vanecek HM, Yates P, Evans DW (2009) Thin Solid Films 517:6287–6289

Gnanam S, Rajendran V (2010) J Sol-Gel Sci Tech 56:128–133

Boyali E, Baran V, Asar T, Ozcelik S, Kasap M (2017) J Alloy Compd 692:119–123

Anitha N, Anitha M, Saravanakumar K, Valanarasu S (2018) J Phys Chem Solids 119:9–18

Anitha M, Amalraj L, Anitha N (2017) Appl Phys A 123:764

Thirumoorthi M, Prakash JTJ (2016) Superlattices Microstruct 89:378–389

Chiad SS, Oboudi SF, Mohamed GH, Habubi NF (2014) PCAIJ 9(6):189–194

Abdelkrim A, Rahmane S, Abdelouahab O, Abdelmalek N, Brahim G (2016) Optik 127:2653–2658

Mariappan R, Ponnuswamy V, Suresh P (2013) Mater Sci Semicond Process 16:825–832

Kumar KDA, Valanarasu S, Tamilnayagam V, Amalraj L (2017) J Mater Sci Mater Electron 28:14209–14216

Sankar C, Ponnuswamy V, Manickam M, Mariappan R, Suresh R (2015) Appl Surface Sci 349:931–939

Perednis D, Gauckler LJ (2005) J Elect Ceram 14(2):103–111

Lokhande BJ, Patil PS, Uplane MD (2004) Mater Chem Phys 84:238–242

Benhaoua B, Abbas S, Rahal A, Benhaoua A, Aida MS (2015) Superlattices Microstruct 83:78–88

Sakhare RD, Khuspe GD, Navale ST, Mulik RN, Chougule MA, Pawar RC, Lee CS, Shashwati Sen, Patil VB (2013) J Alloy Compd 563:300–306

Patil LA, Suryawanshi DN, Pathan IG, Patil DG (2013) Bull Mater Sci 36(7):1153–1160

Turgut G, Keskenler EF, Aydın S, Sonmez E, Dog˘an S, Duzgun B, Ertug˘rul M (2010) Superlattices Microstruct 56:107–116

Paloly A R, Satheesh M, Carmen Martinez-Tomas M, Munoz- Sanjose V, Achary S R, Junaid Bushiri M (2015) Appl Surf Sci 357:915–921

Rahal A, Benhaoua A, Jlassi M, Benhaoua B (2015) Superlattices Microstruct 86:403–411

Suresh R, Ponnuswamy V, Mariappan R, Senthilkumar N (2014) Ceram Int 40:437–445

Mariappan R, Ponnuswamy V, Suresh P, Ashok N, jayamurugan P, Chandra Bose A (2014) Superlattices Microstruct 71:238–249

Raj Mohamed J, Sanjeeviraja C, Amalraj L (2016) J Mater Sci Mater Electron 27:4437–4446

Khelifi Chafia, Attaf Abdallah, Saidi Hanane, Yahia Anouar, Dahnoun Mohamed, Saadi Abdelhakim (2016) Optik 127:11055–11062

Lu YM, Jiang J, Xia C, Kramm B, Polity A, He YB, Klar PJ, Meyer BK (2015) Thin Solid Films 594:270–276

Mrabet C, Boukhachem A, Amlouk M, Manoubi T (2016) J Alloy Compd 666:392–405

Kumar KDA, Valanarasu S, Ganesh V, Shkir Mohd, AlFaify, Algarni H (2018) J Mater Res 33:1523–1533

Kumar KDA, Ganesh V, Valanarasu S, Shkir M, Kulandaisamy I, Kathalingam A, AlFaify S (2018) Mater Chem Phys 212:167–174

Jeong J, Choi SP, Chang CI, Shin DC, Park JS, Lee BT, Park YJ, Song HJ (2003) Solid State Commun 127:595–597

Mariammal RN, Rajamanickam N, Ramachandran K (2011) J Nano-Electron Phys 3:92–100

Mitra A, Thareja RK (2001) J Appl Phys 89:2025–2028

Babar AR, Shinde SS, Moholkar AV, Bhosale CH, Kim JH, Rajpure KY (2011) J Alloy Compd 509:3108–3115

Ergin B, Ketenci E, Atay F (2009) Int J Hydrog Energy 34:5249–5254

Tran Q-P, Fang J-S, Chin T-S (2015) Mater Sci Semicond Process 40:664–669

Deepu DR, Sudha Kartha C, Vijayakumar KP (2016) J Anal Appl Pyrolysis 121:24–28

Prathap P, Subbaiah YPV, Ramakrishna Reddy KT (2007) J Phys D Appl Phys 40:5275–5282

Anand V, Sakthivelu A, Kumar KDA, Valanarasu S, Kathalingam A, Ganesh V, Shkire M, AlFaify S (2018) I S Yahia Ceram Inter 44:6730–6738

Devika M, Koteeswara Reddy N, Ramesh K, Gunasekhar KR, Gopal ESR, Reddy KTR (2006) Semicond Sci Technol 21:1125–1131

Kumar KDA, Valanarasu S, Jeyadheepan K, Kim H-S, Vikraman D (2018) J Mater Sci Mater Electron 29:3648–3656

Joshi BN, Yoon H, Yoon SS (2013) J Electro 71:48–52

Acknowledgements

We are thankful to Dr. R. Ramesh Babu, Assistant Professor, Department of Physics, Bharathidasan University, Tiruchirappalli, India for analyzing the electrical characterization using Hall measurement instrument.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Palanichamy, S., Mohamed, J.R., Kumar, K.D.A. et al. Effect of molar concentration on physical properties of spraydeposited SnO2 thin films using nebulizer. J Sol-Gel Sci Technol 89, 392–402 (2019). https://doi.org/10.1007/s10971-018-4894-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4894-5