Abstract

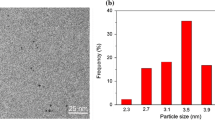

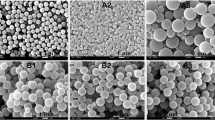

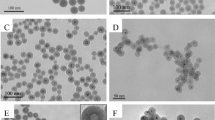

Core–shell silica (SiO2) coated CdS nanorods (NR) and nanospheres (NS) were prepared (SiO2@CdS) by deposition of a Si–O–Si amorphous layer over the CdS surface through the hydrolysis of 3-mercaptopropyltrimethoxysilane and tetraethylorthosilicate. Nanoporous SiO2 matrix (NPSM), hollow SiO2 nanotubes (HSNT) and nanospheres (HSNS) useful for efficient adsorption and catalytic processes were prepared by chemical dissolution of CdS–NS (size: 9–10 nm) and CdS–NR (length: 116–128 nm and width: 6–11 nm) template from SiO2@CdS with 2 M HNO3. These SiO2 nanostructures were characterized by optical absorption, TEM, EDX, SAED and BET surface area analysis. TEM images revealed the fabrication of slightly distorted HSNS (size: 9–12 nm) and closed HSNT (length: 30–45 nm and diameter: 9–14 nm) of shorter dimensions than the CdS–NR template used. The BET surface area (112–134 m2 g−1) of NPSM and HSNS is found to be larger than the surface area (29–51 m2 g−1) of SiO2@CdS composites indicating hollow SiO2 morphology. Silica coated Au (SiO2@Au) composites formed by CdS dissolution from Au (2 wt%) deposited CdS–NR core-encapsulated into SiO2 shell (SiO2@Au–CdS–NR) exhibited a surface plasmon band at 550 nm and displayed high catalytic activity for 4-nitrophenol reduction by Au nanoparticle.

Similar content being viewed by others

References

Liu S, Rao J, Sui X, Cool P, Vansant EF, Tendeloo GV, Cheng X (2008) J Non Cryst Solids 354:826–830

Miyao T, Minoshima K, Naito S (2005) J Mater Chem 15:2268–2270

Hah HJ, Um JI, Han SH, Koo SM (2004) Chem Commun (8):1012–1013

Chen JF, Ding HM, Wang JX, Shao L (2004) Biomaterials 25:723–727

Bae E, Chah S, Yi J (2000) J Colloid Interface Sci 30:367–376

Taniguchi T, Obi S, Kamata Y, Kashiwakura T, Kasuya M, Ogawa T, Kohri M, Nakahira T (2012) J Colloid Interface Sci 368:107–114

Teng F, Tian Z, Xiong G, Xu Z (2004) Catal Today 93–95:651–657

Chah S, Fendler JH, Yi J (2002) J Colloid Interface Sci 250:142–148

Hui YZ, Bin CH, Zhong J, Wei ZW, Yan L (2010) Chin Sci Bull 55:921–926

Mitchell DT, Lee SB, Trofin L, Li N, Nevaanen TK, Soderlund H, Martin CR (2002) J Am Chem Soc 124:11864–11865

Yoon JH, Chae WS, Cho HM, Choi MG, Kim YR (2006) Mater Res Bull 41:1657–1663

Sardar R, Funston AM, Mulvaney P, Murray RW (2009) Langmuir 25:13840–13851

Tao AR, Habas S, Yang P (2008) Small 4:310–325

Wu SH, Tseng CT, Lin YS, Lin CH, Hung Y, Mou CY (2011) J Mater Chem 21:789–794

Park JC, Song H (2011) Nano Res 4:33–49

Pal B, Torimoto T, Ikeda S, Shibayama T, Sugawara K, Takahashi H, Ohtani B (2005) Top Catal 35:321–325

Pal B, Torimoto T, Iwasaki K, Shibayama T, Takahashi H, Ohtani B (2005) J Appl Electrochem 35:751–756

Wei C, Zhou W, Du Y, Xu J, Yang P (2010) Colloid J 72:158–162

Pal B, Torimoto, T, Okazaki, K, Ohtani, B (2007) Chem Commun (5):483–485

Torimoto T, Reyes JP, Iwasaki K, Pal B, Shibayama T, Sugawara K, Takahashi H, Ohtani B (2003) J Am Chem Soc 125:316–317

Lin YS, Wu SH, Tseng CT, Hung Y, Chang C, Mou CY (2009) Chem Commun (24):3542–3544

Gupta N, Pal B (2012) J Colloid Interface Sci 368:250–256

Torimoto T, Hashitani M, Konishi T, Okazaki K, Shibayama T, Ohtani B (2009) J Nanosci Nanotechnol 9:506–513

Yang H (2006) Met Mater Inter 12:351–355

Chang SY, Liu L, Asher SA (1994) J Am Chem Soc 116:6739–6744

Henglein A (1982) J Phys Chem 86:2291–2293

Dijken AV, Janssen AH, Smitsmans HP, Vanmaekelbergh D, Meijerink A (1998) Chem Mater 10:3513–3522

Arellano MA, Ung T, Blanco A, Mulvaney P, Marzán LML (2000) Pure Appl Chem 72:257–267

Chen X, Berger A, Ge M, Hopfe S, Dai N, Gosele U, Schlecht S, Steinhart M (2011) Chem Mater 23:3129–3131

Bergbreiter DE (1999) Angew Chem Int Ed 38:2870–2872

Liu MP, Li CH, Du HB, You XZ (2012) Chem Commun 48:4950–4952

Saunders AE, Popov I, Banin U (2006) J Phys Chem B 110:25421–25429

Khon E, Mereshchenko A, Tarnovsky AN, Acharya K, Klinkova A, Hewa-Kasakarage NN, Nemitz I, Zamkov M (2011) Nano Lett 11:1792–1799

Kaur R, Pal B (2012) J Mol Catal A Chem 355:39–43

Kobayashi Y, Duarte MAC, Marza′n LML (2001) Langmuir 17:6375–6379

Cong H, Toftegaard R, Arnbjerg J, Ogilby PR (2010) Langmuir 26:4188–4195

Pradhan N, Pal A, Pal T (2001) Langmuir 17:1800–1802

Zhang Z, Shao C, Zou P, Zhang P, Zhang M, Mu J, Guo Z, Li X, Wang C, Liu Y (2011) Chem Commun 47:3906–3908

Chang G, Luo Y, Lu W, Qin X, Asiri AM, Al-Youbi AO, Sun X (2012) Catal Sci Technol 2:800–806

Chen J, Dai RJ, Tong B, Xiao SY, Meng WW (2007) Chin Chem Lett 18:10–12

Acknowledgments

We are grateful to the Department of Science and Technology (DST), Govt. of India, for providing financial support for this work. We also thank Dr. Satnam Singh and Mr. Inderpreet Singh Grover for their timely help in surface area measurement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, N., Badhwar, N. & Pal, B. Fabrication of hollow SiO2 and Au (core)–SiO2 (shell) nanostructures of different shapes by CdS template dissolution. J Sol-Gel Sci Technol 68, 284–293 (2013). https://doi.org/10.1007/s10971-013-3165-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-013-3165-8